Sound-blocking sheet member, sound-blocking structure using same, and method for manufacturing sound-blocking sheet member

A manufacturing method, technology of sheet parts, applied in the field of soundproof sheet parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

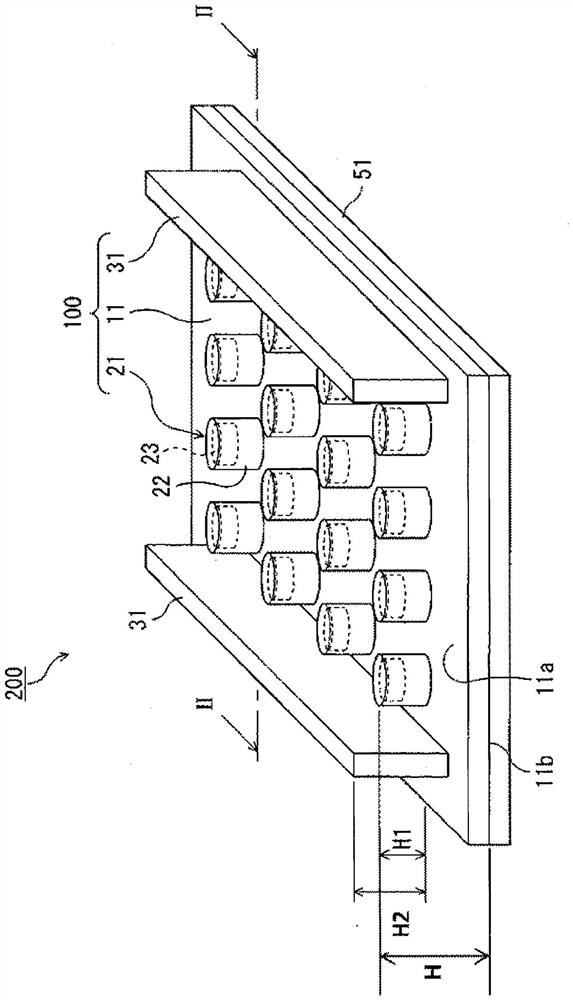

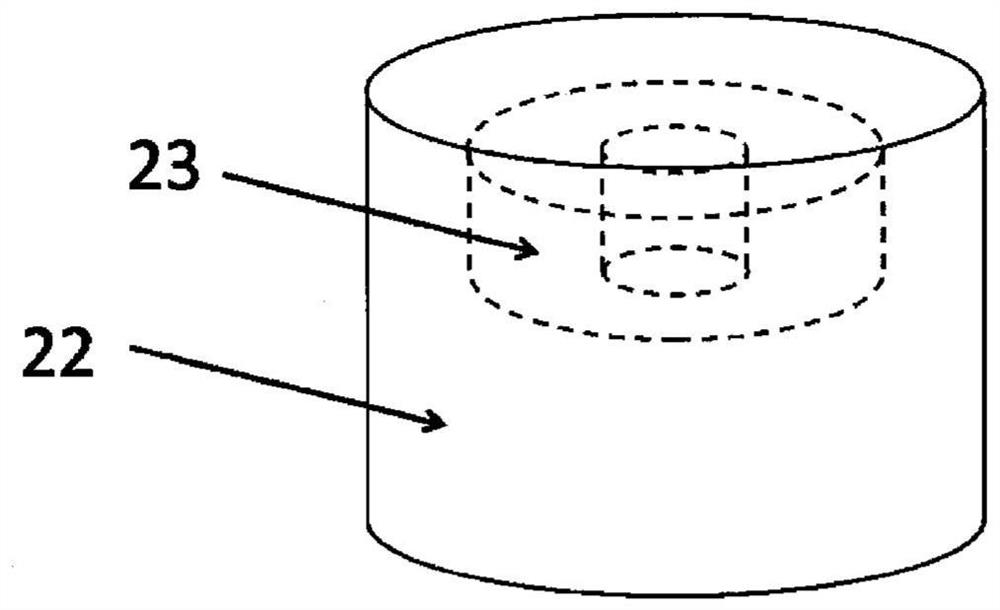

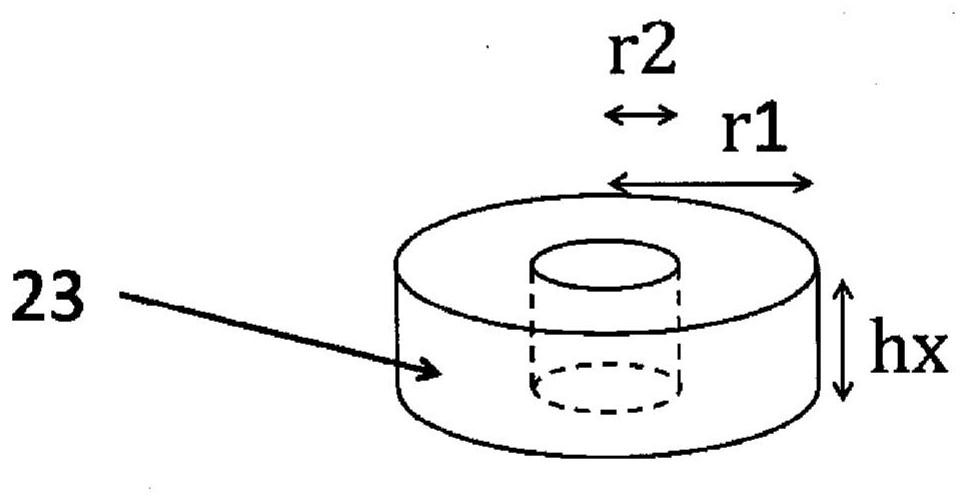

[0169] figure 1 and image 3 It is a schematic perspective view which shows the sound insulation sheet member 100 and the sound insulation structure 200 of this embodiment, and its II-II arrow cross-sectional view. The soundproof sheet member 100 includes: a sheet 11 having rubber elasticity; a plurality of resonance portions 21 provided on the sheet surface 11a of the sheet 11 so as to be in contact with the sheet surface 11a; At least one rib-shaped protrusion 31 on 11a. The sound-insulating sheet member 100 is supported by the support body 51 provided on the sheet surface 11 b side of the sheet 11 , thereby constituting the sound-insulating structure 200 .

[0170]In the sound-insulating sheet member 100 and the sound-insulating structure 200 , for example, when a sound wave is injected from a noise source on the side of the supporting body 51 , resonance of the sheet 11 and / or the resonance portion 21 occurs. At this time, there may be a frequency region in which the di...

no. 2 approach

[0259] Figure 8 It is a schematic perspective view which shows the sound insulation sheet member 101 and the sound insulation structure 201 of this embodiment, and its arrow cross-sectional view. In this embodiment, the sound-insulating sheet member 100 and the sound-insulating structure of the above-mentioned first embodiment are different except that the number of resonance parts, the shape of the base part and the weight part, and the shape and number of the rib-shaped protrusions are different. Body 200 has the same structure, so repeated descriptions are omitted here.

[0260] The resonator 21 of the present embodiment is constituted by a composite structure including a base 24 and a weight 25 supported by the base 24 and having a mass greater than that of the base 24 . In the present embodiment, a plurality of bases 24 having a substantially cylindrical outer shape are also provided on the sheet surface 11 a of the sheet 11 so as to be in contact with the sheet surface...

Embodiment 1

[0323] Example 1 is to include Figure 10A A single unit including the sound insulation sheet parts shown. Table 1 shows the dimensions, materials, and physical properties of the components of the unit cells. The acoustic band gap in the unit monomer is calculated based on the above calculation method.

[0324] As a result of calculation, in Example 1, the acoustic bandgap was 3461-4551 Hz and the normalized acoustic bandgap width was 0.27, and it was confirmed that there is a sufficient sound-insulating bandwidth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com