Method for improving ESD failure of protection ring region of planar Schottky product

A product protection and planar technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unstable operation and damage of electronic and electrical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Shown below with reference to Fig. 1-6; A kind of method that improves planar Schottky product protection ring area ESD failure, is characterized in that, comprises the following steps:

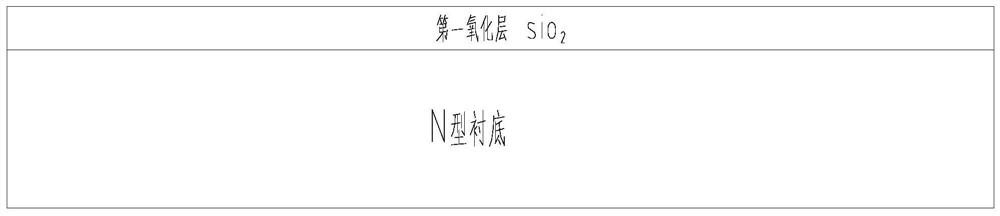

[0031] 1) Grow the first oxide layer (sio) on the surface of the N-type substrate (wafer) 2 ),Such as figure 1 shown;

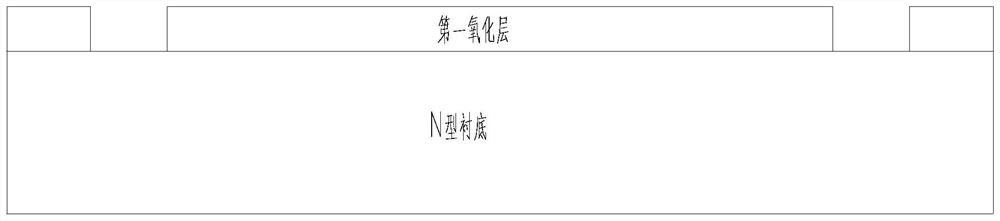

[0032] 2) Perform a photolithography process on the first oxide layer (the photolithography process includes glue coating, exposure and development; the purpose of the photolithography process is to transfer the pattern from the photolithography plate to the photoresist to the oxide layer, which belongs to the prior art), And through the wet process in the prior art, a ring-shaped groove is etched on the first oxide layer (the purpose of etching the ring-shaped groove is to reserve a region for implanting doping), such as figure 2 shown;

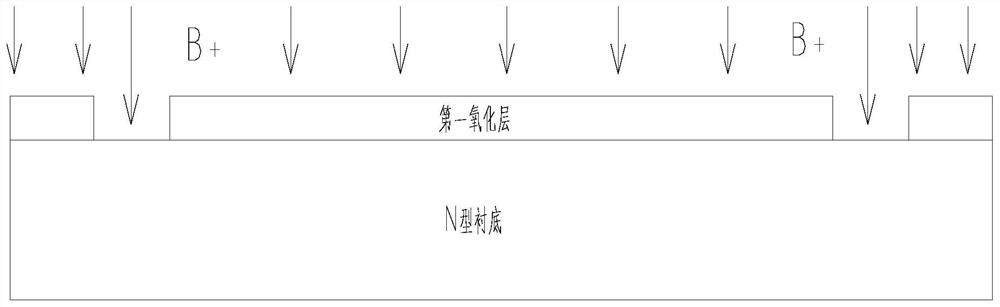

[0033] 3) Remove the surface photoresist and implant B elements; change the charge distribution in the annular groove area, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com