Static contact for switch cabinet, and switch cabinet

A switchgear and static contact technology, applied in electrical switches, contacts, contact meshing, etc., can solve the problem of high manufacturing cost of switchgear, and achieve the effects of improving heat dissipation efficiency, reducing costs, and improving current capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

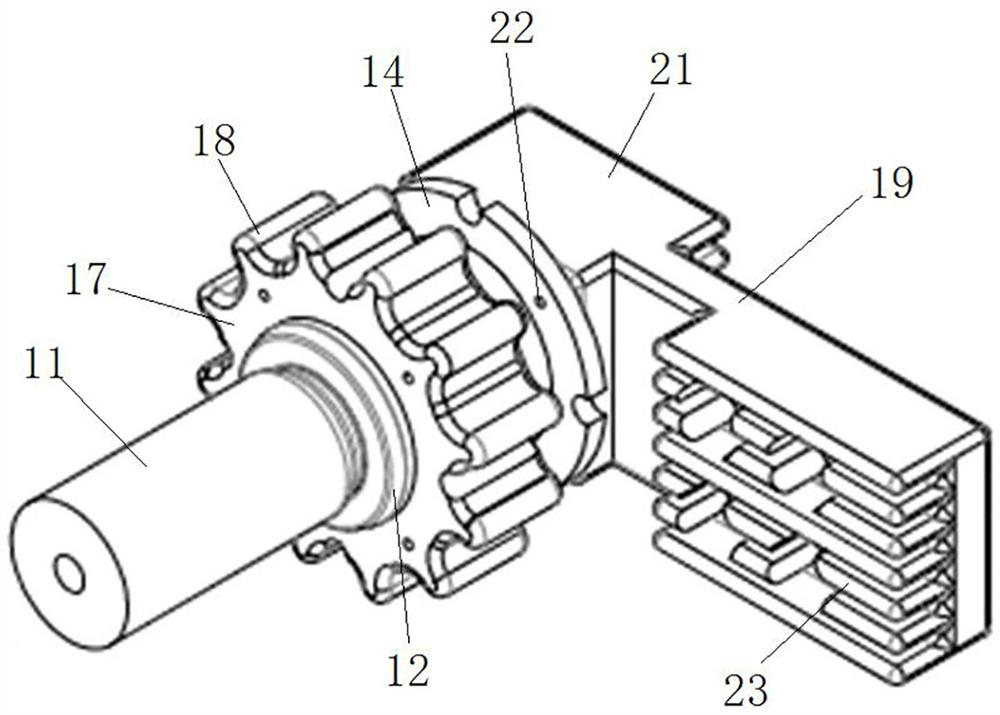

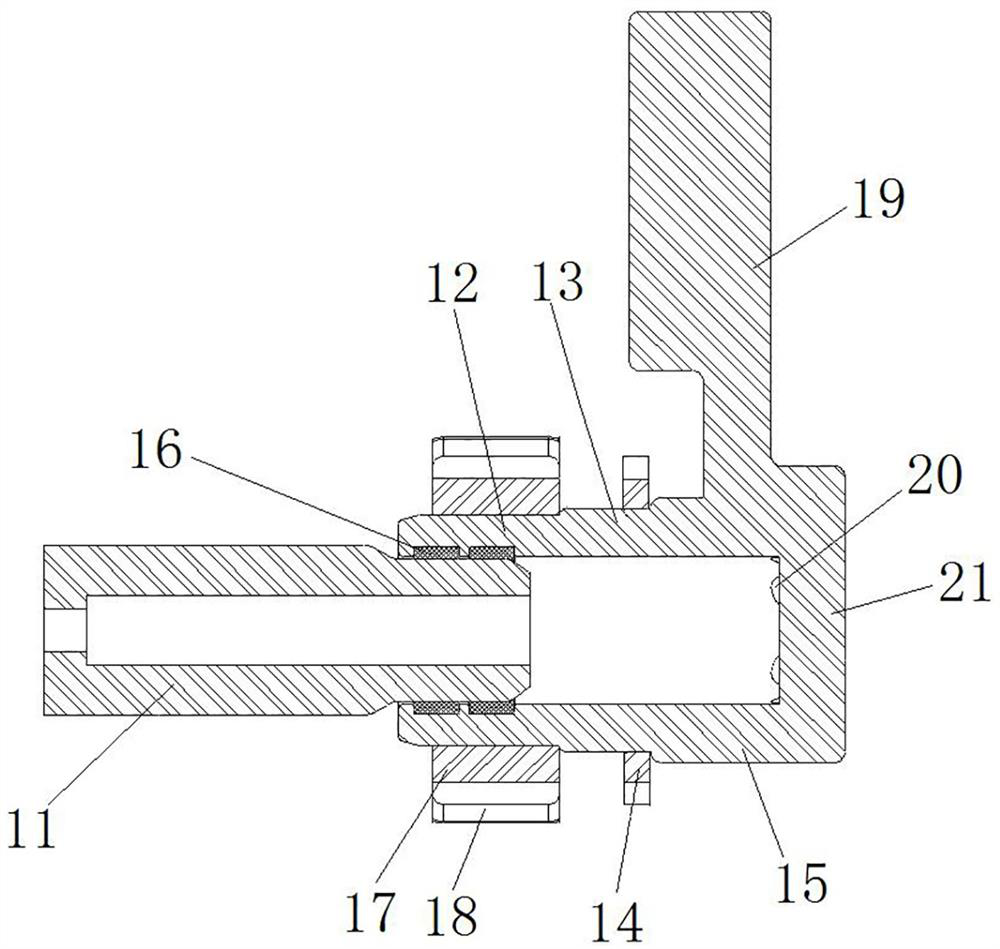

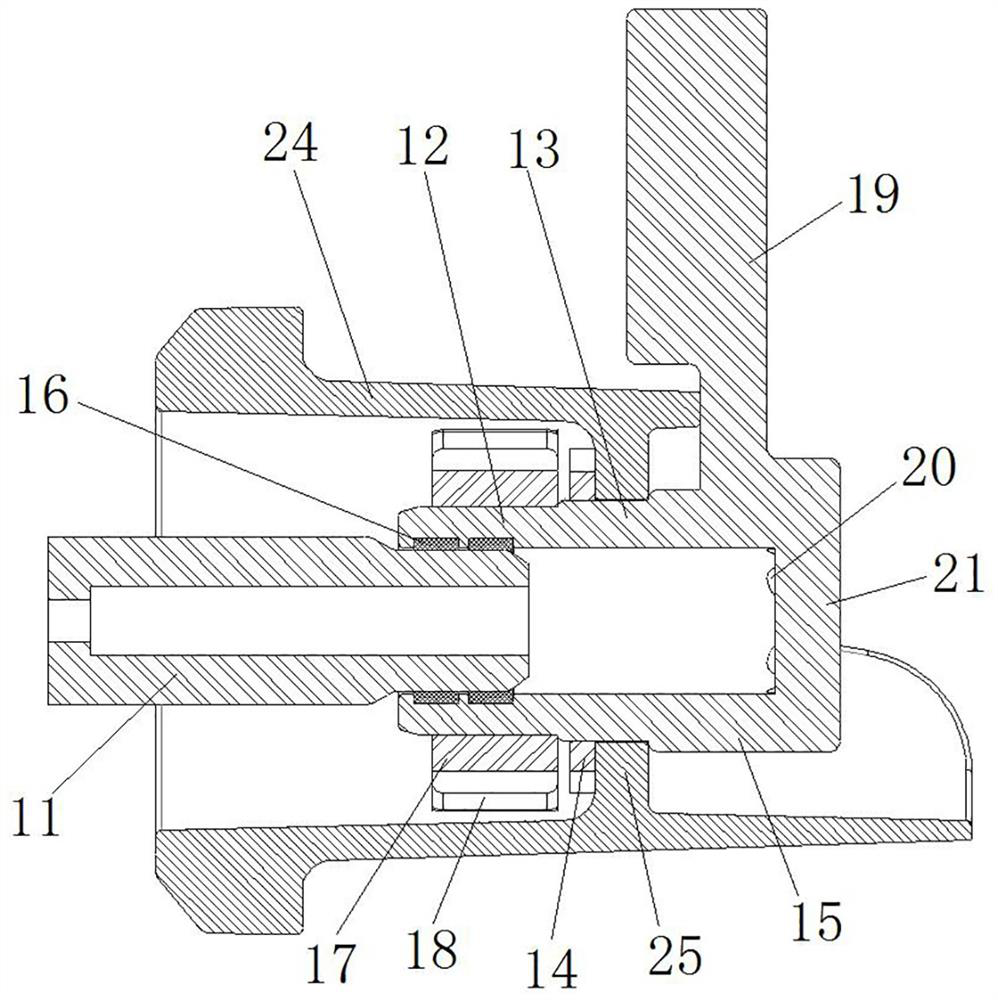

[0056] Such as figure 1 with figure 2 As shown, the static contact for switchgear includes a contact body, and the contact body includes a mating section 12, a small-diameter section 13 of the contact, a large-diameter section 15 of the contact, and a bus connection section 19, the mating section 12, the small-diameter section of the contact 13. The large-diameter section 15 of the contact and the connecting section 19 of the busbar are integrally formed, which makes the processing of the contact body convenient and stable in performance. Wherein, the small-diameter section 13 of the contact and the large-diameter section 15 of the contact jointly constitute a fixed part.

[0057] In this embodiment, the mating section 12, the small-diameter section 13 of the contact, and the large-diameter section 15 of the contact are connected in sequence, and all three are cylindrical structures; the mating section 12 is inserted into the contact arm 11 on the circuit breaker, mated The...

Embodiment 2

[0069] The difference between this embodiment and the first embodiment is that in embodiment 1, the static contact includes a mating section 12, a small-diameter contact section 13 and a large-diameter section 15 of the contact, and a fixing nut 14 is threaded on the small-diameter section 13 of the contact. The static contact is fixed in the contact box 24 through the fixing nut 14, and the mating section 12 is inserted into the contact arm. In this embodiment, the static contact only includes a mating section, a fixing hole is provided at the bottom of the mating section, and an insert is embedded in the contact box, and the static contact is fixed on the insert by screws to realize fixing on the contact box. inside the header box.

Embodiment 3

[0071] The difference between this embodiment and the first embodiment is that in embodiment 1, the contact small-diameter section 13 is located between the contact large-diameter section 15 and the mating section 12, and the heat dissipation device is detachably fixed on the mating section 12. The section 12, the small-diameter section 13 of the contact, the large-diameter section 15 of the contact and the busbar connection section 19 are integrally formed, and the static contact is loaded from the right side of the partition 25 as a whole when assembled. In this embodiment, the cooling device is integrally formed on the mating section, and the large-diameter section of the contact is detachably connected to the small-diameter section of the contact. When the static contact is assembled, the mating section and the small-diameter section of the contact are installed from the left side of the partition. The large-diameter section of the contact is loaded from the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com