Winding stator core heading shield

A stator core and shield technology, which is applied in the field of stator core shields with windings, can solve the problems of damage to the insulation layer on the surface of enamelled copper wires, solder splashing, etc., and achieve simple manufacturing, reduced insulation faults, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

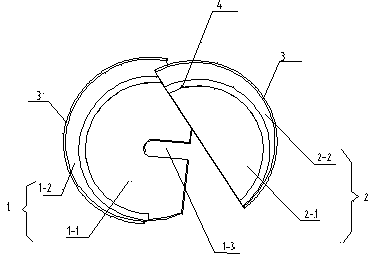

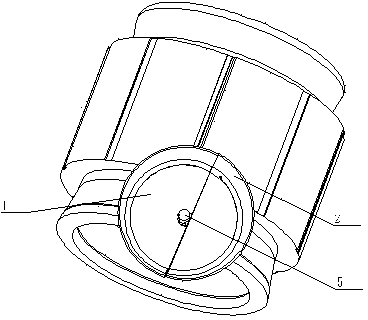

[0012] as attached figure 1 As shown, there is a winding stator core head shield, including a left shield 1 and a right shield 2, the left shield and the right shield are respectively provided with a base plate, the right base plate 2-1 is semicircular, and the left base plate 1-1 is a large semicircle, and the left base plate is provided with a horizontal notch 1-3 from the center of the circle to the straight edge of the plate body, and the left and right base plates are respectively provided with semicircular upright hoardings fixed along the arc edge of the plate body, See attached figure 1 Left upright hoarding 1-2 and right upright hoarding 2-2 shown in . During making, left upright coaming board 1-2 and right upright coaming board 2-2 are processed by thin steel plate, avoid damage winding, as attached figure 1 As shown, the upper edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com