Preparation method of functional coating with surface insulation defect self-diagnosis and electric field intelligent regulation and control functions

A surface insulation and self-diagnosis technology, applied in coatings, conductive paints, luminous paints, etc., can solve problems such as surface insulation defects, high degree of electric field distortion on the surface of insulating parts, and insulation failures of power equipment, etc., to achieve uniform electric field distribution and optimization Electric field distribution along the surface, applicable to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

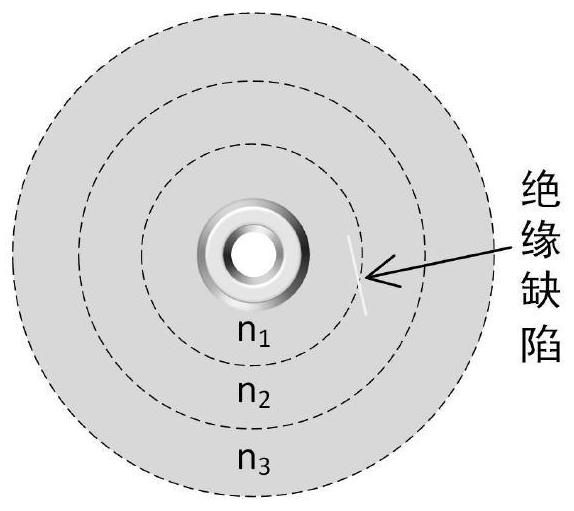

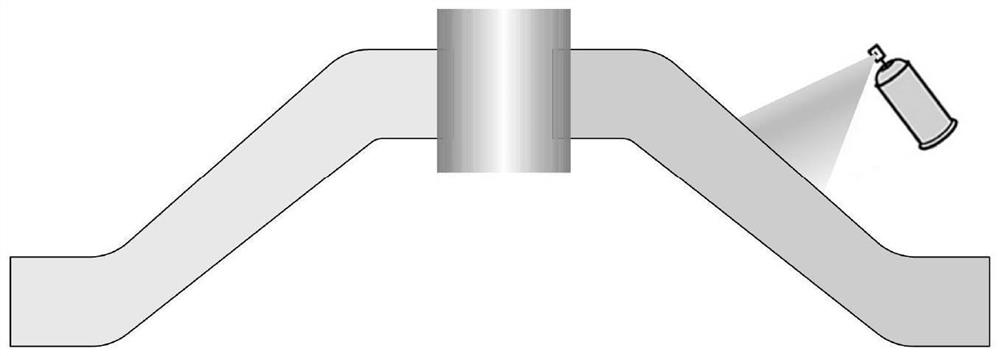

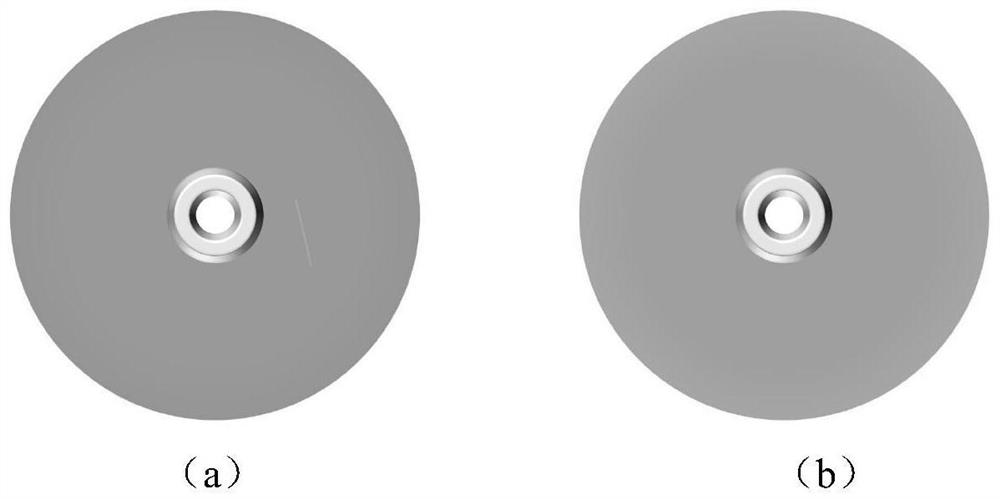

[0030] The purpose of the present invention is to provide a method for preparing a functional coating for self-diagnosis of creeping insulation defects and intelligent electric field regulation. The light intensity distribution in the area with surface insulation defects on the surface of the insulating member changes significantly, and the functional coating has the function of electric field regulation. The probability of insulation failure, the present invention provides a brand new method for the detection of creeping insulation defects of power insulation parts. The specific implementation steps are as follows:

[0031] 1) Add CT-5531 type epoxy resin, polyimide resin HY-651 curing agent, RF-2-α type alumina filler, DMP-30 type accelerator according to the mass ratio of 100:33:330:0.2 The epoxy vacuum pouring device is uniformly mixed and vacuumed. The temperature in the vacuum mixing chamber is set to 100 ° C, and the stirring time is set to 30 minutes. After mixing eve...

Embodiment 2

[0040] The silicone rubber insulating material is selected as the polymer matrix, which is sprayed into the insulating part, and other steps are the same as those in Example 1.

Embodiment 3

[0042] The polymer matrix is made of polyethylene insulating material, which is deposited in the insulating member, and other steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com