Infrared accurate temperature measurement-based composite insulator insulation defect detection method

A technology for composite insulators and accurate temperature measurement, which is applied in the direction of material thermal development, etc., to achieve the effect of improving accuracy, reducing misjudgment rate, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Composite insulator insulation defect detection method based on infrared precise temperature measurement,

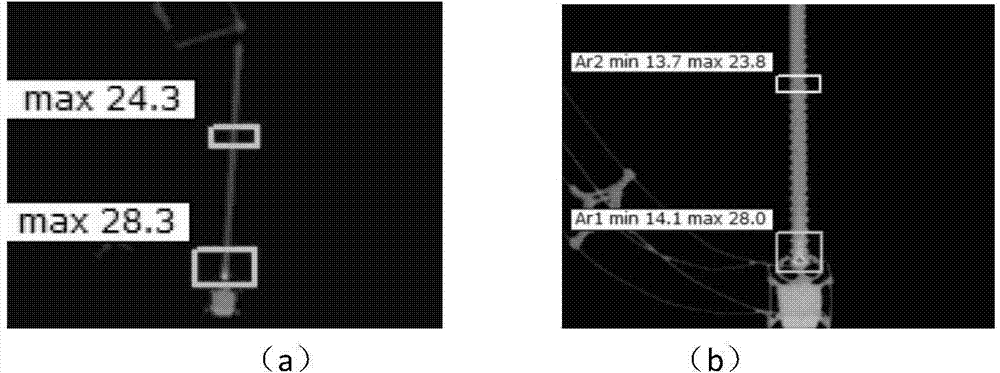

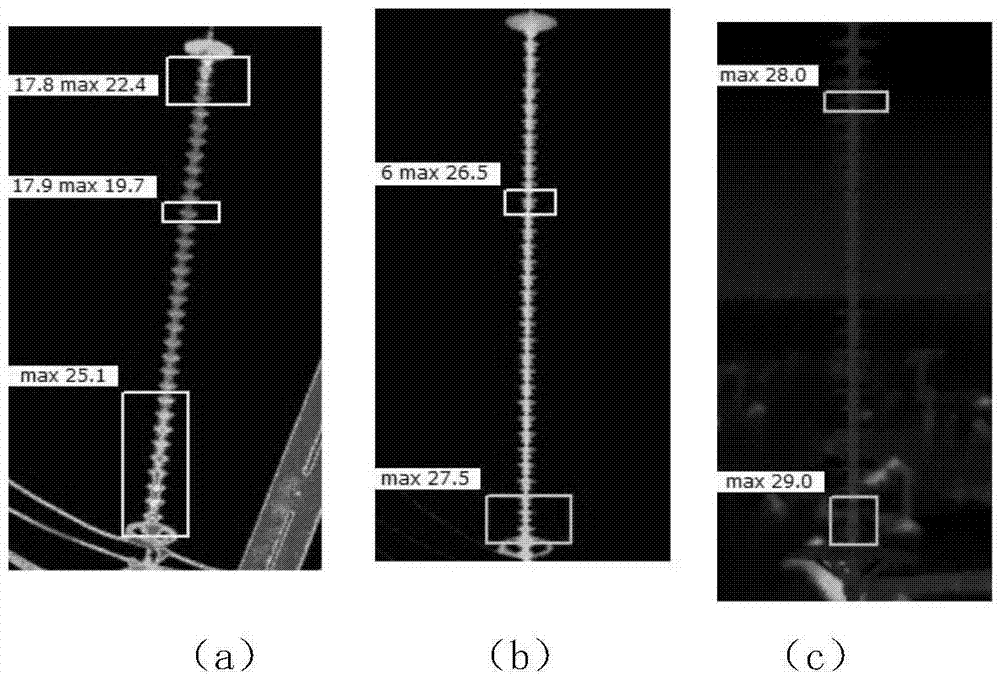

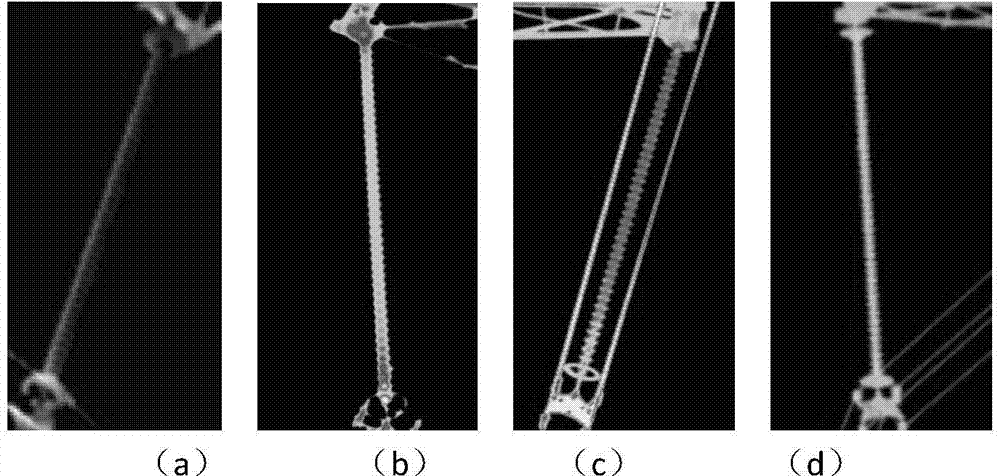

[0034] When detecting three-phase or double-string composite insulators in the same tower, the method steps for judging whether there is an insulation defect in the composite insulator by using the infrared temperature measurement image taken by the infrared thermal imager are as follows:

[0035] (1) According to the different temperatures represented by different colors in the thermal image, judge whether there is an abnormal heating part on the composite insulator. If there is no abnormal heating part, it is considered that the equipment is normal. If there is an abnormal heating part, go to step (2);

[0036] (2) Compare the temperature difference between the highest temperature of the abnormal heating part and the ambient temperature, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com