Method for online monitoring of fault of insulator based on thermal infrared imaging technology

A technology of thermal infrared imaging and insulators, which is applied in the direction of using optical methods for testing, measuring electricity, and measuring devices. It can solve problems such as high sensitivity and low cost, temperature and humidity, microwave incident angle and antenna beam influence, and bulky devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

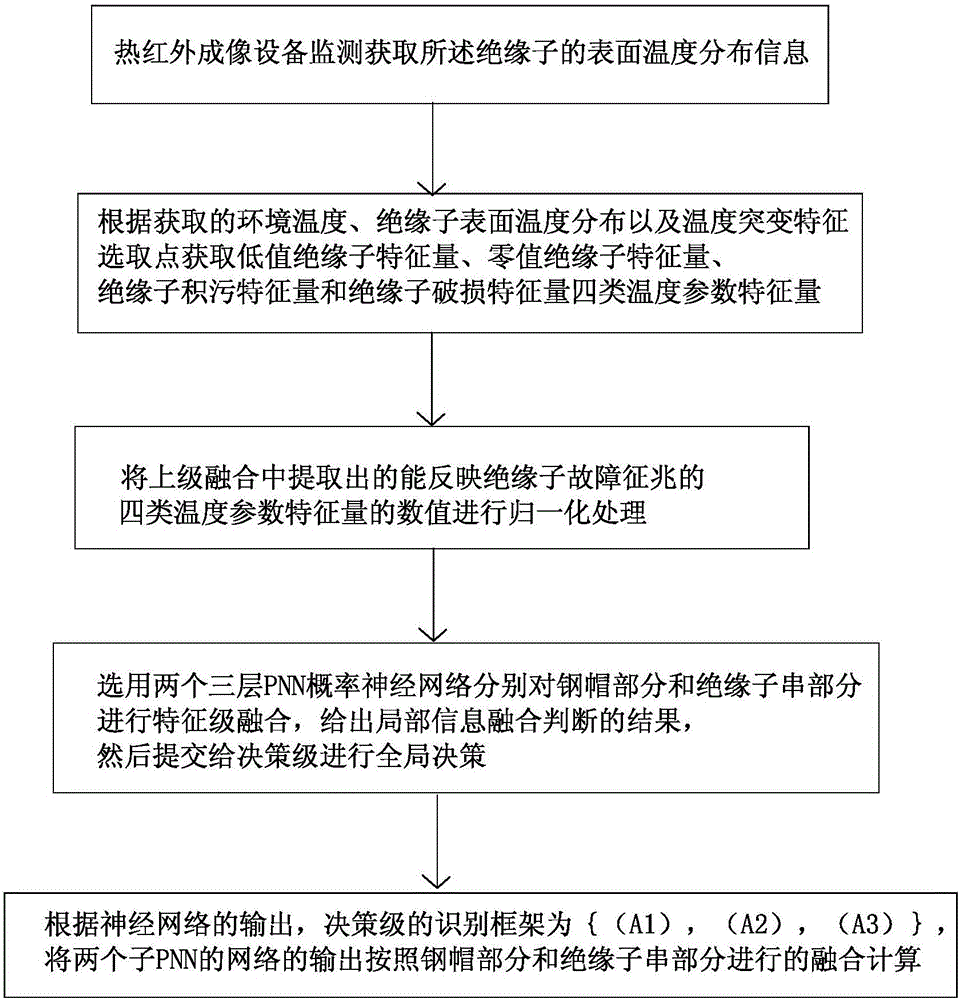

[0027] Such as figure 1 As shown, a method for on-line monitoring of insulator faults based on thermal infrared imaging technology includes the following steps:

[0028]1) A thermal infrared imaging device is set up on the insulator at a long distance, and the surface temperature distribution information of the insulator is obtained through the monitoring of the thermal infrared imaging device;

[0029] 2) According to the obtained ambient temperature, insulator surface temperature distribution and temperature mutation feature selection points, four types of temperature parameter feature quantities are obtained: low-value insulator feature quantity, zero-value insulator feature quantity, insulator pollution feature quantity and insulator damage feature quantity;

[0030] 3) Normalize the values of the characteristic quantities of the four types of temperature parameters that can reflect the symptoms of insulator faults extracted from the upper-level fusion, and normalize all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com