An energy-saving hidden frame glass aluminum composite curtain wall structure

An energy-saving, glass technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor sealing effect and sound insulation effect, reduced service life, and the insulating glass is divided into two pieces, so as to achieve the effect of convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

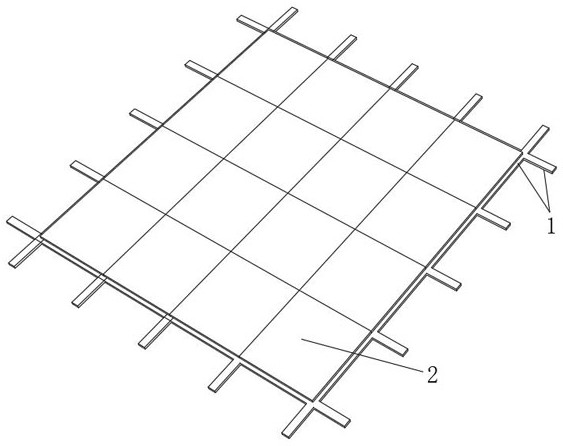

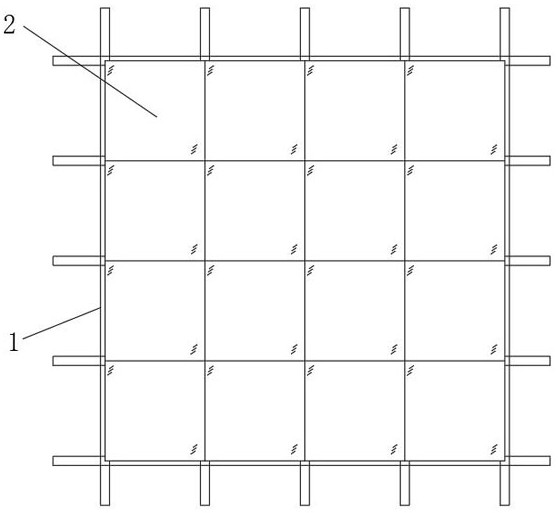

[0042] see Figure 1-10 , an energy-saving hidden frame glass-aluminum panel composite curtain wall structure, comprising a shaped frame 1, a composite double-layer glass 2 is fixedly installed on the left side of the shaped frame 1, a right-angle mounting part 3 is fixedly installed on the left end of the shaped frame 1, and a right-angle mounting part The upper surface of 3 is fixedly installed with a lateral support panel 4, the front inner end of the lateral support panel 4 is fixedly connected with an anti-displacement 5, the upper side of the anti-dislocation 5 is fixedly installed with an installation piece 6, and the bottom of the composite double-layer glass 2 The inner side is fixedly connected with a glass installation assembly 7, and the lower side of the glass installation assembly 7 is provided with an installation slot 8, and the interior of the installation slot 8 is fixedly installed with a fixed column 9, and the left and right sides of the glass installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com