Crude oil pour point depressant

A technology for pour point and depressant of crude oil, used in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problem of pour point reduction of high pour point crude oil, and achieve good pour point depressant effect, enhanced polarity, and good synergy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

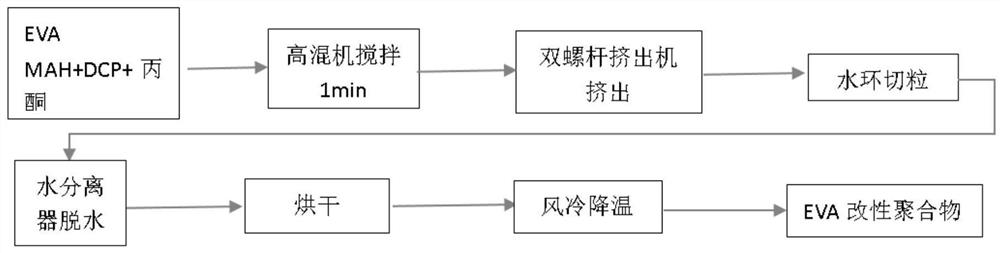

[0047] In the embodiment of the present application, the preparation method of the modified ethylene vinyl acetate copolymer comprises:

[0048] 1) mixing and dissolving the organic peroxide and the maleic anhydride in an organic solvent to obtain a mixture;

[0049] 2) mixing the mixture with the ethylene vinyl acetate copolymer;

[0050] 3) Extrude with an extruder, shape and dry to obtain the modified ethylene vinyl acetate copolymer.

[0051] Optionally, the preparation method consists of the above steps.

[0052] In the embodiment of the present application, the organic solvent described in step 1) is selected from any one or more of acetone, petroleum ether and ethyl acetate; the sum of the organic peroxide and the maleic anhydride and The weight ratio of the organic solvent is (1 to 2): (1 to 3).

[0053] In the embodiment of the present application, the extruder described in step 3) is a parallel co-rotating twin-screw extruder, the screw speed is 30r / min to 50r / min...

Embodiment 1

[0055] In this example, the ethylene-vinyl acetate copolymer was purchased from Arkema Company, 28-800 grade;

[0056] Octadecylphenol polyoxyethylene polyoxypropylene ether was purchased from Jiangsu Haian Chemical Factory Company, P184 brand;

[0057] The isomerized cetane solvent oil is purchased from Guangdong Qixu Chemical Co., Ltd., IP16 brand;

[0058] The mixed aromatics are purchased from Beijing Defu Daye Co., Ltd., with a density of 0.85g / cm 3 to 0.91g / cm 3 , Closed flash point 65 ℃ to 75 ℃.

[0059] Add 1 weight part maleic anhydride (MAH) with 100 weight parts ethylene-vinyl acetate copolymer EVA (vinyl acetate VA content 28%, melt index 800g / 10min), 0.1 weight part initiator dicumyl peroxide ( DCP), melt grafting to obtain a modified ethylene-vinyl acetate copolymer, that is, a modified EVA copolymer. The preparation process is as follows:

[0060] Dissolve dicumyl peroxide (DCP) and maleic anhydride (MAH) in acetone (the weight ratio of dicumyl peroxide and...

Embodiment 2

[0064] In this example, the ethylene-vinyl acetate copolymer was purchased from Korea Hyundai Company, EVA810 brand;

[0065] Octadecylphenol polyoxyethylene polyoxypropylene ether was purchased from Jiangsu Haian Chemical Factory, P184 brand;

[0066] The isomerized cetane solvent oil is purchased from Guangdong Qixu Chemical Co., Ltd., IP16 brand;

[0067] Described mixed aromatics is identical with mixed aromatics in embodiment 1;

[0068] With 100 parts by weight of ethylene-vinyl acetate copolymer EVA (vinyl acetate VA content 33%, melt index 45g / 10min) add 0.8 parts by weight of maleic anhydride (MAH), 0.06 parts by weight of initiator dicumyl peroxide ( DCP), melt grafting to obtain modified ethylene-vinyl acetate copolymer, namely modified EVA copolymer. The preparation process is the same as in Example 1. Based on the weight of the modified ethylene-vinyl acetate copolymer, the graft rate of the modified ethylene-vinyl acetate copolymer is 0.6wt.%; the crosslinking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com