High-weather-resistance self-cleaning anti-icing coating and preparation method thereof

An anti-icing and self-cleaning technology, applied in coatings and other directions, can solve problems such as high-voltage power transmission, icing of towers and bridge cables, potential safety hazards, economic losses, etc. The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

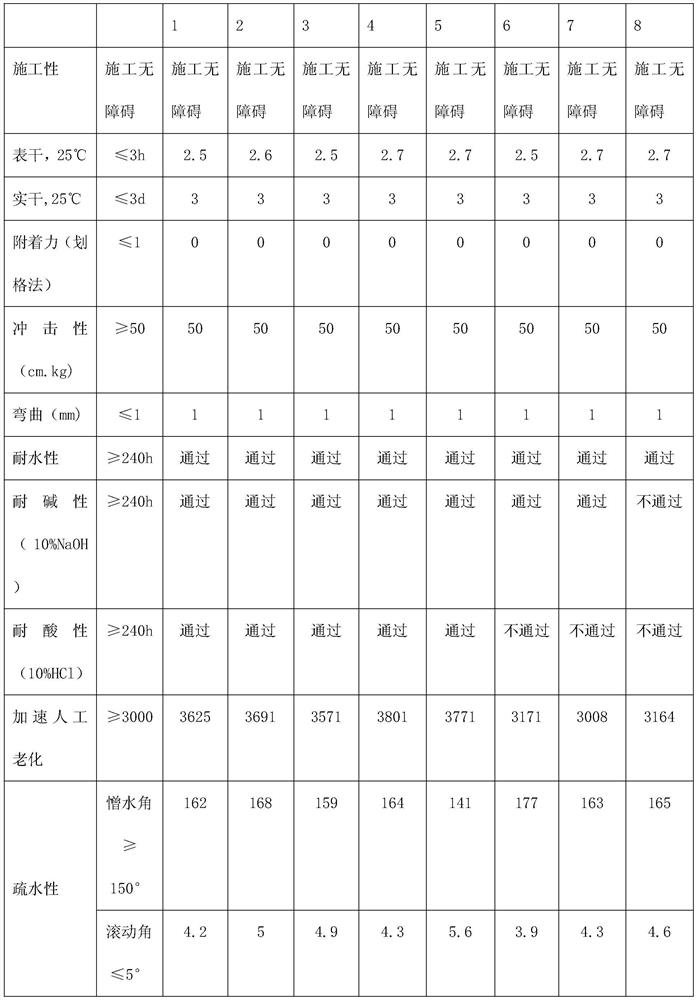

Examples

Embodiment 1

[0027] Take 15 parts by mass of the modified PDMS polymer and add 60 parts of fluororesin, 34 parts of organic solvent, 0.5 part of wetting agent, and 0.5 part of defoamer in turn under stirring, and keep the rotation speed of the stirring shaft at 900-1000 rpm Every minute, mix for 30 minutes, and then use a 300 mesh filter to filter to obtain component A;

[0028] Mix 80 parts by mass of HDI derivatives with 20 parts of butyl acetate, stir while mixing, keep the stirring speed at 1000 rpm, mix for 30 minutes, and filter through a 300-mesh filter to obtain component B.

Embodiment 2

[0030] Take 15 parts by mass of the modified PDMS polymer and add 60 parts of fluororesin, 34 parts of organic solvent, 0.5 part of wetting agent, and 0.5 part of defoamer in turn under stirring, and keep the rotation speed of the stirring shaft at 900-1000 rpm Every minute, mix for 30 minutes, and then use a 300 mesh filter to filter to obtain component A;

[0031] Mix 70 parts by mass of HDI derivatives with 30 parts of butyl acetate, stir while mixing, keep the stirring speed at 1000 rpm, mix for 30 minutes, and filter through a 300-mesh filter to obtain component B.

Embodiment 3

[0033] Take 20 parts by mass of the modified PDMS polymer, add 50 parts of fluororesin, 29.8 parts of organic solvent, 0.1 part of wetting agent, and 0.1 part of defoamer in turn under stirring, and keep the rotation speed of the stirring shaft at 900-1000 rpm Every minute, mix for 30 minutes, and then use a 300 mesh filter to filter to obtain component A;

[0034] Mix 80 parts by mass of HDI derivatives with 20 parts of butyl acetate, stir while mixing, keep the stirring speed at 1000 rpm, mix for 30 minutes, and filter through a 300-mesh filter to obtain component B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com