Preparation method of laser 3D-printed complex-configuration silicon carbide composite part

A 3D printing and composite material technology, which is applied in the field of laser 3D printing complex configuration silicon carbide composite material parts to achieve high reliability, optimized performance, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

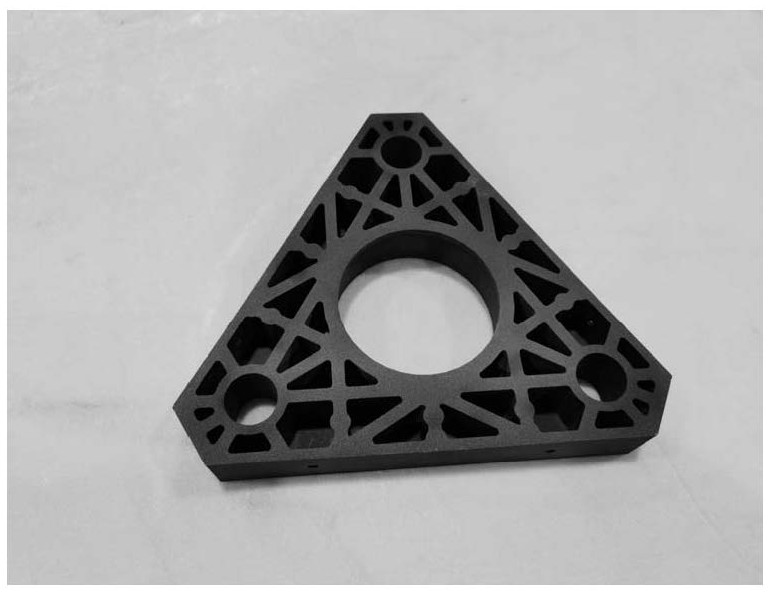

preparation example Construction

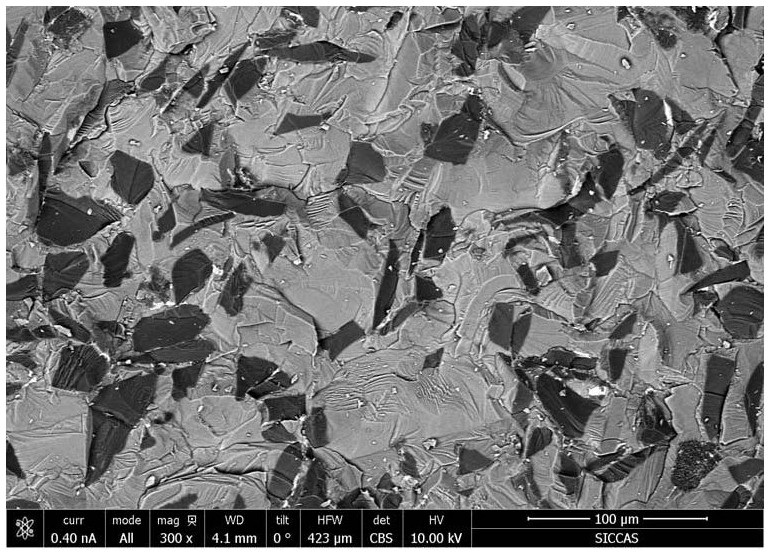

[0040] The preparation method of the present invention does not require fiber preform molding or mold manufacturing processes, the molding process is simple and easy to control, it is easy to regulate the percentage of chopped carbon fibers in a wide range, and the introduction of multi-phase powder makes it homogeneously compounded. Adjust the composition ratio of organic and inorganic powder materials in a wide range, so as to fully optimize and improve the performance of composite materials, and realize the stable manufacture of silicon carbide composite products with complex configurations, especially with unique advantages in the manufacture of special structural parts.

[0041] The silicon carbide composite material part obtained by the preparation method has a three-dimensional uniform macroscopic and microscopic structure. In some embodiments, the silicon carbide composite part has a relative density of ~51% and a three-point bending strength of ~5 MPa.

Embodiment 1

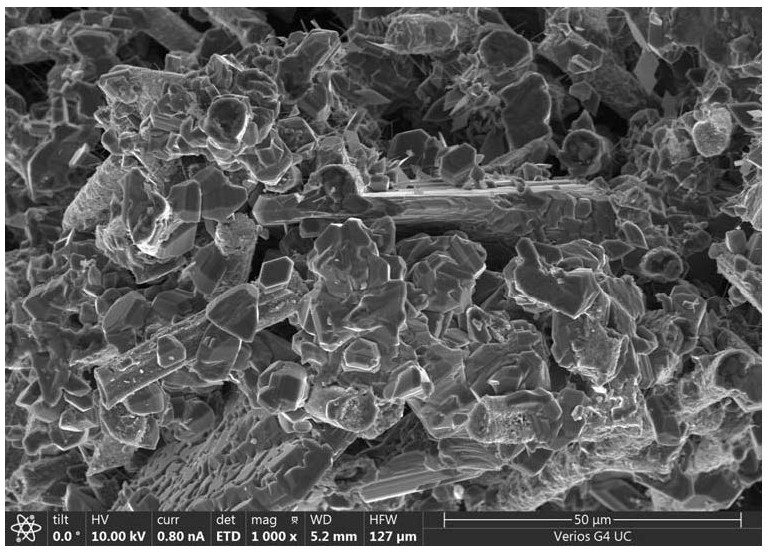

[0044] (1) In the stirring mixer, add 10vol% of chopped carbon fiber powder with a length and diameter of 60 μm and 6 μm respectively, 20 vol% of silicon carbide powder with an average particle size of 30 μm, and phenolic resin with an average particle size of 70 μm in proportion by volume 50vol%, 20vol% carbon black with an average particle size of 10μm. The stirring speed of the stirring mixer is controlled to 200 rpm, and the stirring time is 10 minutes to form a compounded homogeneous multi-phase powder.

[0045] (2) By means of laser 3D printing, the homogeneous multi-phase powder is printed and formed to obtain a silicon carbide composite material blank. The laser 3D printing system is: CO 2 The laser power is 35W, the powder coating thickness is 0.1mm, and the powder bed preheating temperature is 70°C.

[0046] (3) The green body formed by laser printing was degreased in a vacuum atmosphere, and the temperature of the green body was raised to 600 °C in vacuum at a hea...

Embodiment 2

[0049] (1) In the stirring mixer, add 20vol% of chopped carbon fiber powder with a length and diameter of 150 μm and 6 μm respectively, 45 vol% of silicon carbide powder with an average particle size of 80 μm, and phenolic resin with an average particle size of 20 μm in proportion by volume 30vol%, 5vol% carbon black with an average particle size of 5μm. The stirring speed of the stirring mixer is controlled to 250 rpm, and the stirring time is 30 minutes to form a compounded homogeneous multi-phase powder.

[0050] (2) By means of laser 3D printing, the homogeneous multi-phase powder is printed and formed to obtain a silicon carbide composite material blank. The laser 3D printing system is: CO 2 The laser power is 60W, the powder coating thickness is 0.06mm, and the powder bed preheating temperature is 90°C.

[0051] (3) The green body formed by laser printing was degreased in a vacuum atmosphere, and the temperature of the green body was raised to 550° C. in vacuum at a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com