A kind of waterproof mortar and its preparation method and application

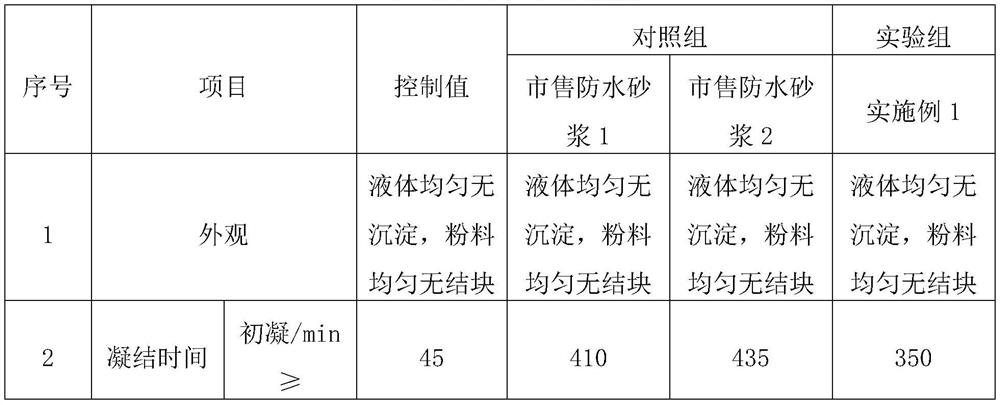

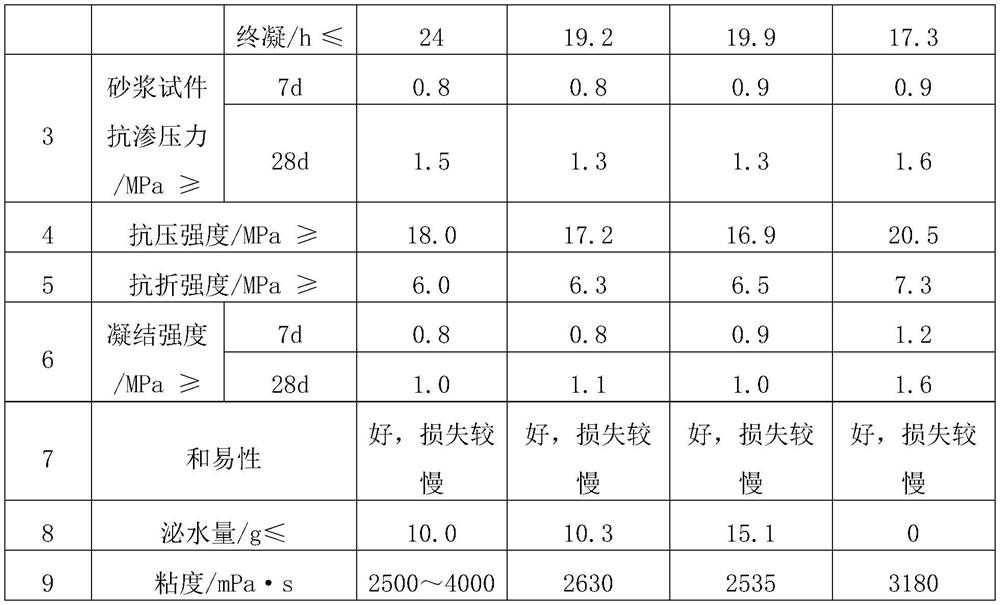

A waterproof mortar and water reducing agent technology, applied in the field of waterproof mortar and its preparation, can solve the problems of long setting time, compressive/flexural strength and viscosity reduction, high bleeding, etc., to achieve high compressive and flexural strength, Strong scratch resistance and low bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The present invention also provides a method for preparing the above waterproof mortar, wherein the liquid material components and the powder material components are mixed and stirred evenly; wherein,

[0093] Liquid components include:

[0094] Styrene-acrylate copolymer emulsion: 20-50 parts;

[0095] Vinyl acetate-ethylene copolymer emulsion: 10-40 parts;

[0096] Workability improver: 10-20 parts;

[0097] Film-forming aids: 1 to 5 parts;

[0098] Defoamer: 0.3 to 0.9 parts;

[0099] Water: 15 to 60 parts;

[0100] Powder components include:

[0101] Portland cement: 10 to 40 parts;

[0102] Aluminate cement: 5 to 40 parts;

[0103] Gypsum: 5 to 17 parts;

[0104] Glass sand: 25 to 50 parts;

[0105] Glass powder: 5 to 15 parts;

[0106] Water reducing agent: 0.1 to 0.5 parts;

[0107] Stabilizer: 0.05 to 0.3 parts;

[0108] Coagulant: 0.05~0.5 part;

[0109] Fiber: 0.1 to 1 part.

[0110] Compared with the prior art, the preparation method of the wate...

Embodiment 1

[0117] The liquid component and powder component of waterproof mortar are prepared in the following proportions, wherein,

[0118] Liquid components: 500g styrene-acrylate copolymer emulsion, 100g vinyl acetate-ethylene copolymer emulsion, 100g sodium polyacrylate derivative, 5g triterpenoids, 50g propylene glycol butyl ether, 9g polysiloxane organics, water 236g;

[0119] Powder components: ordinary Portland cement 150g, aluminate cement 300g, gypsum 80g, granulated blast furnace slag powder 30g, (70-140) mesh glass sand 280g, 200 mesh glass powder 120g, calcite powder 40g, naphthalene series Water reducing agent 4g, higher fatty acid 5g, hydroxypropyl methylcellulose (8000 viscosity) 0.7g, Brunei gum 0.3g, potassium silicate 0.3g, crystal nucleus nano-enhancer 0.3g, sodium gluconate 0.1g, basalt Mineral fiber 1g, polypropylene fiber 1.5g;

[0120] Take 500g of liquid material component and 1000g of powder material component and mix and stir evenly to obtain waterproof mort...

Embodiment 2

[0122] The liquid component and powder component of waterproof mortar are prepared in the following proportions, wherein,

[0123] Liquid ingredients: 450g styrene-acrylate copolymer emulsion, 120g vinyl acetate-ethylene copolymer emulsion, 130g sodium polyacrylate derivative, 6g triterpenoids, 40g propylene glycol butyl ether, 8g polysiloxane organics, water 246g;

[0124] Powder components: ordinary Portland cement 200g, aluminate cement 250g, gypsum 70g, granulated blast furnace slag powder 40g, (70-140) mesh glass sand 300g, 200 mesh glass powder 100g, calcite powder 40g, naphthalene series Water reducer 4g, zinc stearate 5g, hydroxypropyl methylcellulose (8000 viscosity) 0.7g, Brunei gum 0.3g, potassium silicate 0.2g, crystal nucleus nano-enhancer 0.3g, sodium hexametaphosphate 0.2 g. Basalt mineral fiber 1g, polypropylene fiber 1.5g;

[0125] Take 400g of liquid material components and 1000g of powder material components and mix and stir evenly to obtain waterproof mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com