Laser irradiation device and surface roughening method using same

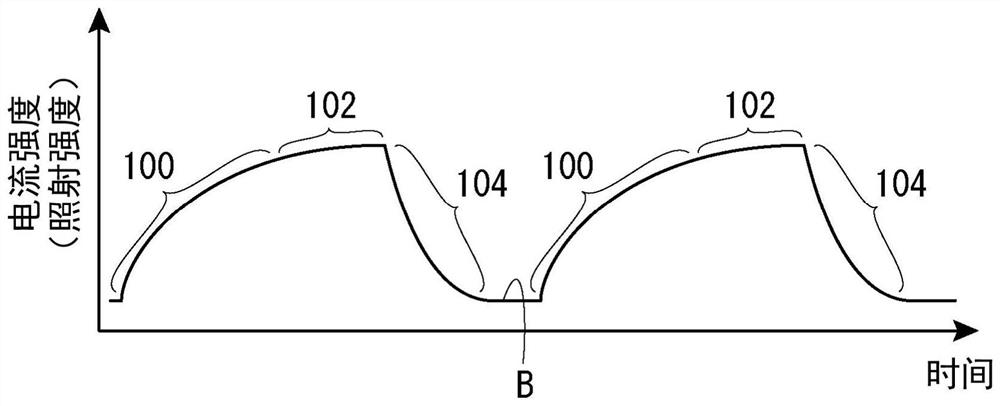

A surface roughening and laser irradiation technology, which is applied in laser welding equipment, manufacturing tools, welding/welding/cutting items, etc., can solve problems such as sandpaper quality deviation, achieve the effect of reducing damage and avoiding peak current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

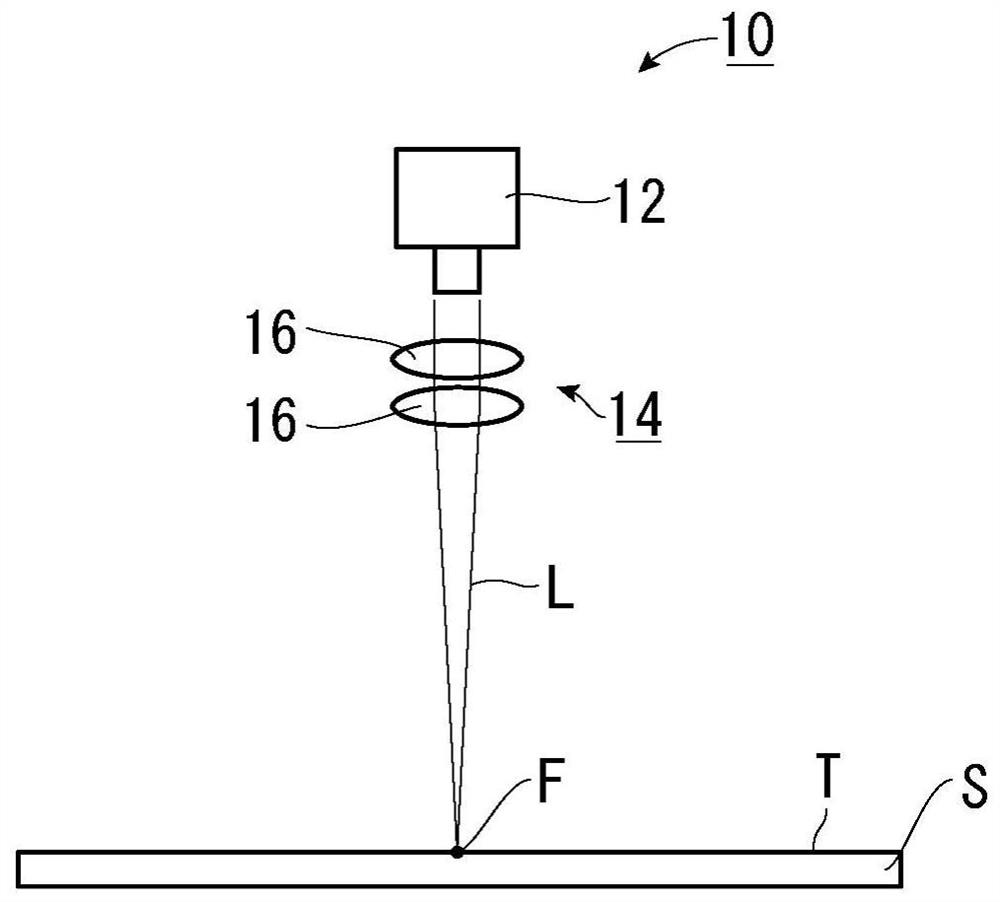

[0056]In the above embodiment, a laser irradiation apparatus 10 is constituted by a set of laser light source 12 and the collecting member 14, but a plurality of laser light sources 12 and a collecting member 14 may be combined to constitute a laser irradiation device 10.

[0057]Such asFigure 6 As shown, the laser irradiation apparatus 10 according to the modification 1 is composed of, for example, by combining 5 groups of laser light source 12 and the collecting member 14.

[0058]The focus position F of the laser light L light L-facing member S is set to a given interval, respectively, respectively, and each focus position F is arranged.

[0059]When such a laser irradiation apparatus 10 is integrally in the direction (hereinafter, referred to as "longitudinal") in the direction (hereinafter, referred to as "longitudinal"), and is called "longitudinal"). When irradiating the laser light L, ifFigure 7 As shown, the surface T of the component S can form a concave portion X in a checkerboard...

experiment example

[0061]In the case where the laser irradiation apparatus 10 is irradiated with the surface T of the CFRP material (component S) formed by substantially parallel to a large amount of carbon fibers, the diameter of each recessed portion X formed by each laser light L The interval size of the focus positions f between each laser light L is in the width direction, and the longitudinal interval size as a parameter, the preferred longitudinal interval size is confirmed. Further, the direction of the carbon fiber contained in the CFRP material (component S) is consistent with "longitudinal".

[0062]The component S is fixed, and the laser irradiation apparatus 10 is irradiated with a laser light L of the pulse-shaped waveform at a given time interval while moving on the longitudinal direction. Therefore, the surface shape of each of the recess X is a longitudinal longitudinal elliptical shape. Hereinafter, the length of the longitudinal direction in the surface shape of the concave portion X i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com