High-precision high-strength carbon fiber thin-wall pipe end face connecting structure

A technology of high-strength carbon fiber and thin-walled pipes, which is applied in the direction of connecting components, rod connections, mechanical equipment, etc., and can solve problems such as poor aesthetics, inability to cut pipes precisely, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

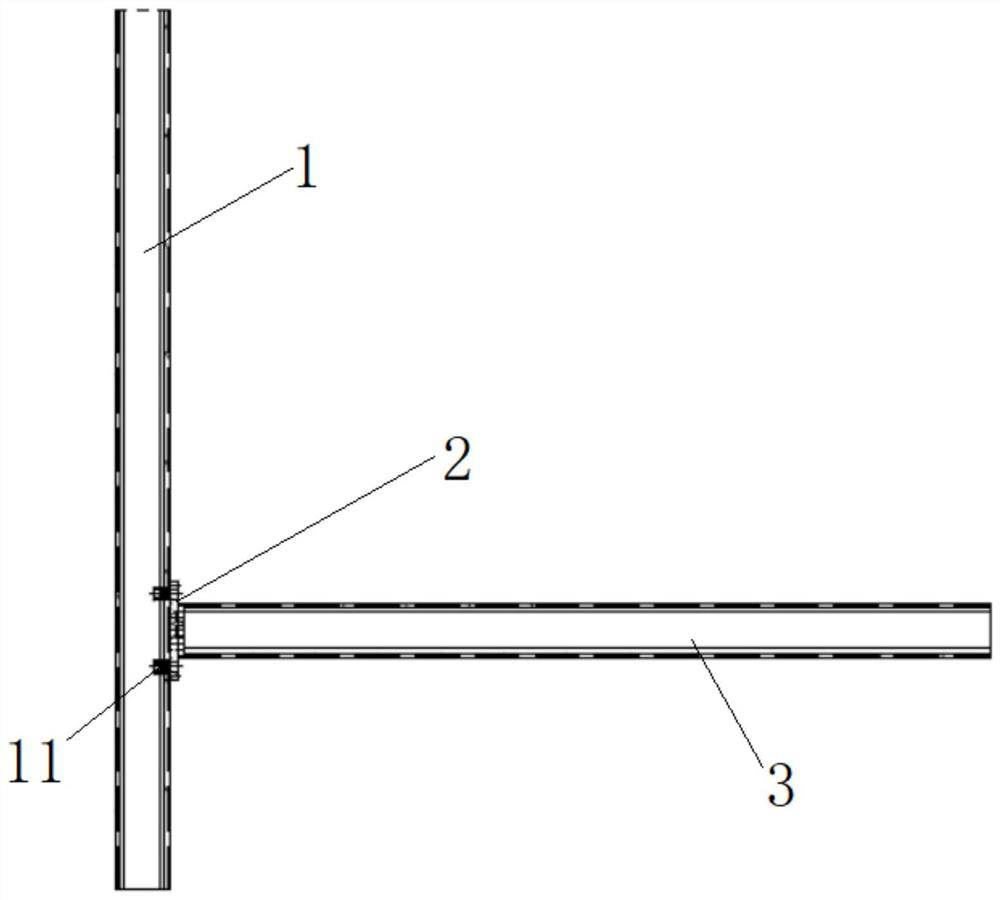

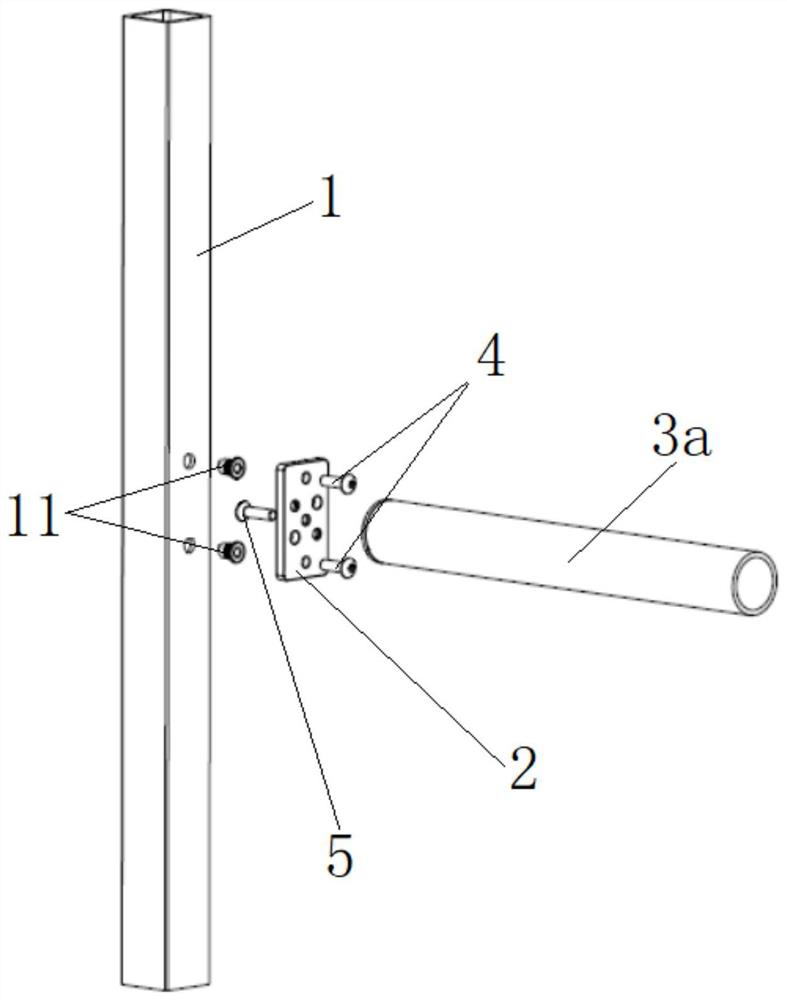

[0032] Such as figure 1 , figure 2 and Figure 4 As shown, a high-precision, high-strength carbon fiber thin-walled pipe end surface connection structure of the present invention includes a square tube 1, a connecting piece 2 fixed to the side wall of the square tube 1, and a connecting piece 2 fixed to the side of the square tube 1. Connecting pipe 3, square pipe 1 is provided with at least two rivet nuts 11; connecting piece 2 is provided with fixed taper hole (here is central fixed taper hole 22a), connecting pipe (here is circular connecting pipe 3a) The end facing the connecting piece 2 has an end surface (not marked), and the connecting piece 2 is fixed to the end surface by a number of reverse screws 5 embedded in the central fixing taper hole 22a; the connecting piece 2 is provided with a matching blind rivet nut on the side facing the square tube 1 11, the connecting piece 2 is fixed on the blind rivet nut 11 through the forward screw 4 passing through the counterb...

Embodiment 2

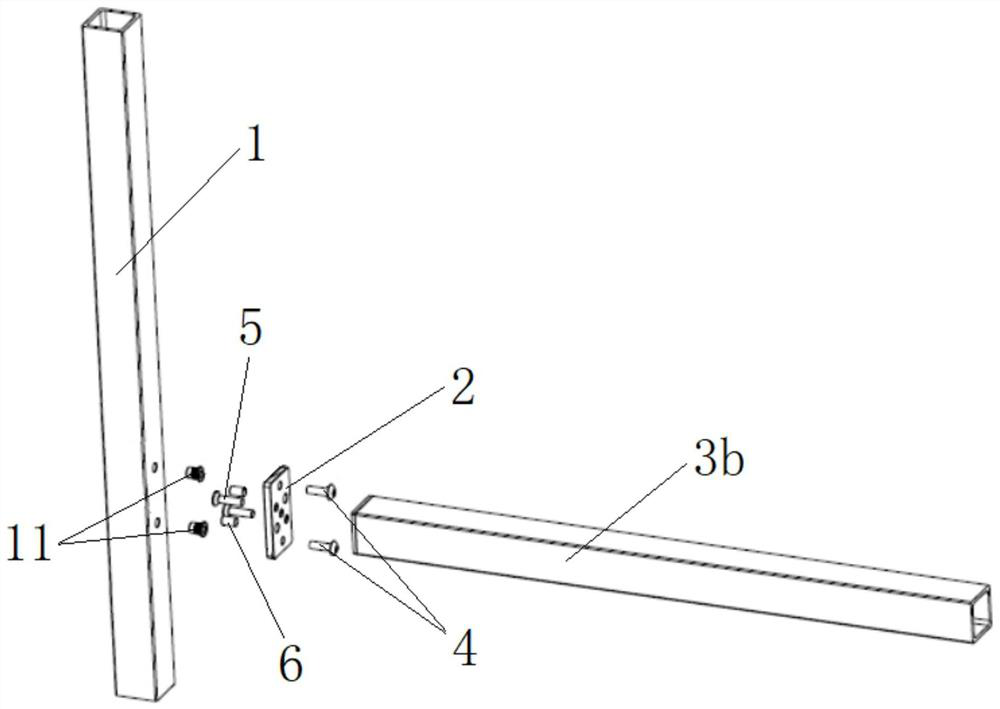

[0036] Such as figure 1 , image 3 and Figure 4 As shown, the difference from Example 1 is that the connecting pipe is a square connecting pipe 22b, the connecting piece 2 has two diagonal fixing taper holes 22b, and the reverse screw 4 passes through the diagonal fixing taper holes 22b to connect with the square The end face of the tube 3b is fixed. When the connecting pipe is a square connecting pipe 22b, its relative position to the connecting piece 2 is determined by the diagonal line, which can prevent the position accuracy deviation caused by the angle.

[0037] Such as image 3 and Figure 4 As shown, the connecting piece 2 is also provided with a diagonal pin hole 23, and the diagonal line where the diagonal pin hole 23 is located is perpendicular to the diagonal line where the diagonally fixed taper hole 22b is located. Corresponding to the pin hole (not exposed) of the corner pin hole 23 , the diagonal pin hole 23 and the pin hole are butted through the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com