Current limiter, compressor and air conditioner

A current limiter and current limiting technology, applied in the direction of machine/engine, mechanical equipment, high-efficiency adjustment technology, etc., can solve the imbalance of centrifugal inertia force of single eccentric block, affect the lubrication effect of compressor parts, and easily generate vibration and noise, etc. problem, to achieve the effect of good automatic adjustment, clever design, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

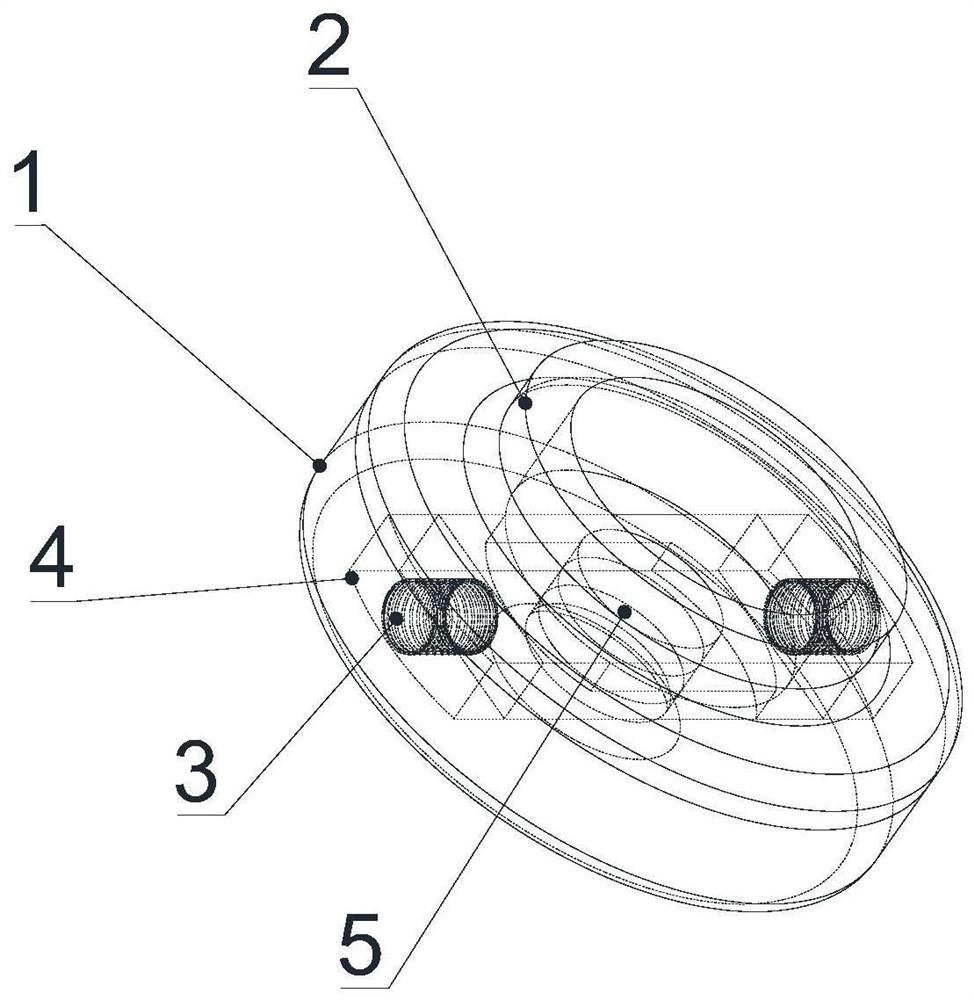

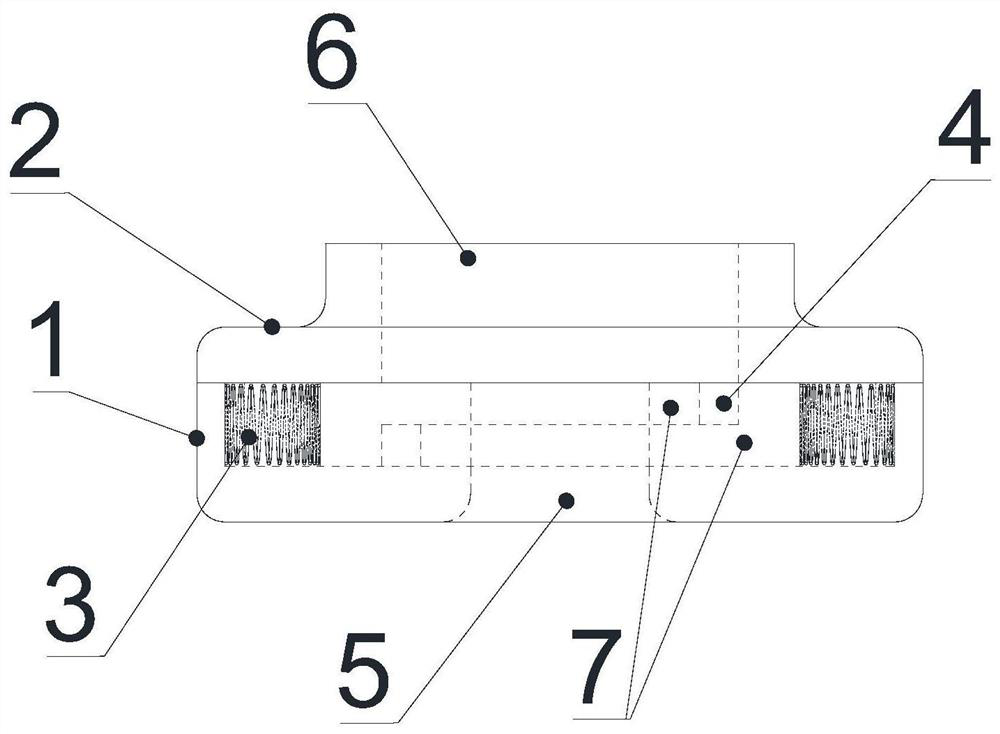

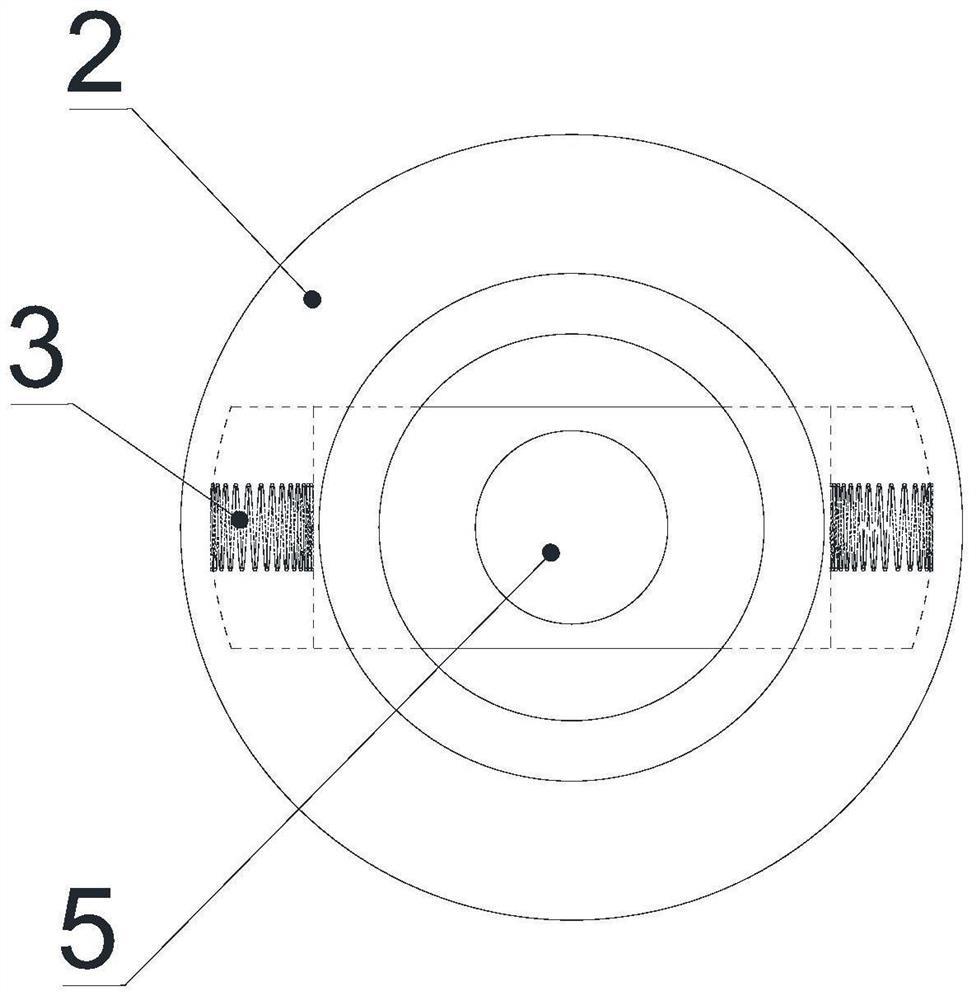

[0031] see Figure 1-Figure 6 , the flow limiter of this embodiment includes a seat body and a sliding flow limiting assembly; wherein, an oil inlet channel 5 is provided in the center of the inner cavity of the seat body, and the oil inlet channel 5 is arranged through the seat body along the axial direction; the compressor The lower end of the crankshaft is connected to the top of the seat body, and the central oil passage of the crankshaft communicates with the oil inlet passage 5;

[0032] The sliding current limiting assembly includes two sliding current limiting parts 7, the two sliding current limiting parts 7 are oppositely arranged in the inner cavity of the seat, and the two sliding current limiting parts 7 are superimposed on each other; the two sliding current limiting parts Elastic elements 3 are provided between the part 7 and the inner cavity wall of the seat, and transition holes 11 are provided on the two sliding flow limiting parts 7; when the compressor is i...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the inner wall of the connection hole 6 on the flow limiting cap is provided with a threaded structure. In this way, the lower end of the crankshaft and the flow limiting cap can be connected through a threaded structure, making disassembly and assembly more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com