A kind of high-strength modified asphalt and preparation method thereof

A technology for modifying asphalt and polymer modifiers, which is applied in building components, building insulation materials, buildings, etc., and can solve the problem of strict mixing temperature requirements for asphalt mixtures, unfavorable long-term production and product storage, and easy pollution of pipelines and siltation. tank bottom and other problems, to achieve the effect of improving high temperature performance and low temperature performance, stable storage and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

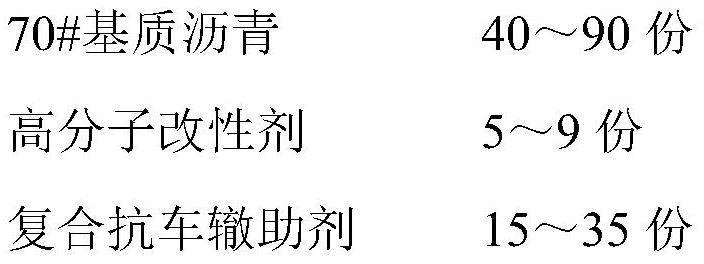

Method used

Image

Examples

Embodiment 1

[0055] Prepare the high-strength modified asphalt of the present invention, specifically:

[0056] S1. Weigh 50g of linear SBS modifier and SEBS modifier (SBS: SEBS=3:2), 1000g of Ssangyong 70# base asphalt, and 150g of composite anti-rutting additive (asphalt particles: Qingchuan Rock asphalt=2:1), 5g of butylated hydroxyanisole, 30g of furfural extract oil, 2g of sulfur stabilizer;

[0057] S2. Heat 70# base asphalt to a flowing state at a temperature of 180°C to 190°C, stir and preheat for 0.5h, add a composite anti-rutting aid, and stir and develop at a temperature of 180±5°C for 2h;

[0058] S3. Then add a polymer modifier, use a shearing machine for 0.5h at 170±5°C, and then stir and develop at 175±5°C for 2h;

[0059] S4. Then add furfural to extract the oil, stir and develop at 175±5°C for 0.5h, and then add butylated hydroxyanisole to stir and develop for 1h;

[0060] S5. Finally, add sulfur stabilizer, stir and develop at 185℃±5℃ for 4-5h to obtain high-strength mo...

Embodiment 2

[0063] S1. Weigh 70g of linear SBS and SEBS polymer modifier (SBS: SEBS=3:4), 1000g of Ssangyong 70# base asphalt, and 150g of composite anti-rutting additive (asphalt particles: Qingchuanyan asphalt=2:1) , 5g of butylated hydroxyanisole, 30g of furfural extract oil, 2g of sulfur stabilizer;

[0064] S2. Heat the 70# base asphalt to a fluid state at a temperature of 180°C to 190°C, stir and preheat for 0.5h, add a composite anti-rutting aid, and stir and develop at a temperature of 180±5°C for 2h;

[0065] S3. Then add a polymer modifier, use a shearing machine for 0.5h at 170±5°C, and then stir and develop at 175±5°C for 2h;

[0066] S4. Then add furfural to extract the oil, stir and develop at 175±5°C for 0.5h, and then add butylated hydroxyanisole to stir and develop for 1h;

[0067] S5. Finally, add sulfur stabilizer, stir and develop at 185℃±5℃ for 4-5h to obtain high-strength modified asphalt.

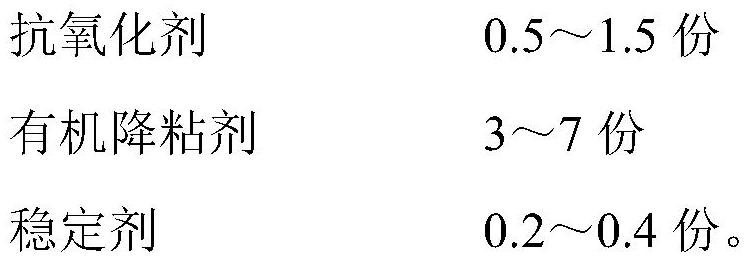

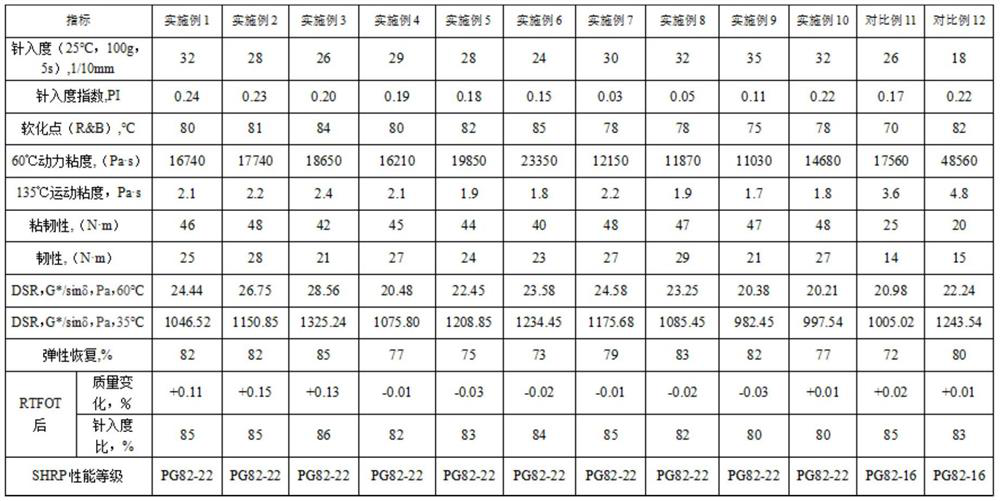

[0068] Its performance is tested, and the test results are shown in Table ...

Embodiment 3

[0070] S1. Weigh 90g of SBS modifier and SEBS polymer modifier (SBS: SEBS=1:2), 1000g of 70# base asphalt, and 150g of composite anti-rutting additive (asphalt particles: Qingchuanyan asphalt=3:1) , 5g of butylated hydroxyanisole, 30g of furfural extract oil, 2g of sulfur stabilizer;

[0071] S2. Heat 70# base asphalt to a flowing state at a temperature of 180°C to 190°C, stir and preheat for 0.5h, add a composite anti-rutting aid, and stir and develop at a temperature of 180±5°C for 2h;

[0072] S3. Then add a polymer modifier, use a shearing machine for 0.5h at 170±5°C, and then stir and develop at 175±5°C for 2h;

[0073] S4. Then add furfural to extract the oil, stir and develop at 175±5°C for 0.5h, and then add butylated hydroxyanisole to stir and develop for 1h;

[0074] S5. Finally, add sulfur stabilizer, stir and develop at 185℃±5℃ for 4-5h to obtain high-strength modified asphalt.

[0075] Its performance is tested, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com