Device transfer printing treatment method and miniature microphone dustproof device transfer printing treatment method

A treatment method and technology of dust-proof device, which is applied in the direction of transferring ink from original manuscripts, printing of special varieties of printed matter, printing, etc., can solve problems such as easy peeling of devices and affect device performance, so as to improve product performance and increase anchorage. Dot area and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

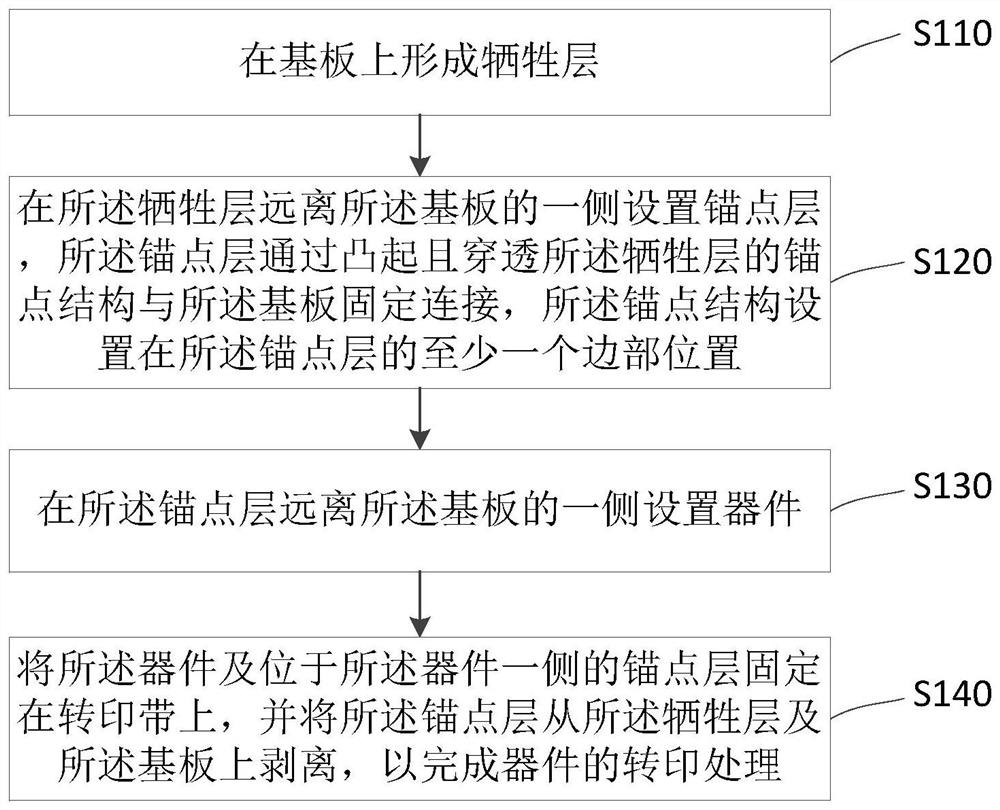

[0032] FIG. 1 shows a flow of a device transfer processing method according to an embodiment of the present invention.

[0034] S110: Lay a sacrificial layer material on the substrate and form a sacrificial layer.

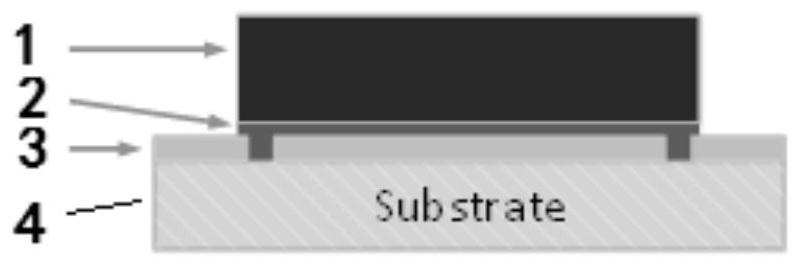

[0035] S120: An anchor point layer is provided on the side of the sacrificial layer away from the substrate, and the anchor point layer passes through the protrusions thereon and penetrates the sacrificial layer.

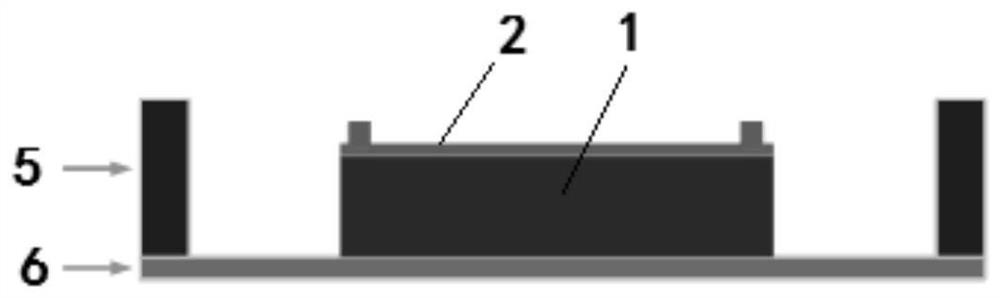

[0037] Since in the peeling process of the transfer belt, the separation of the anchor point structure and the sacrificial layer is gradually peeled off in one direction,

[0038] In a specific embodiment of the present invention, the anchor point structure can be set at the four edge positions of the anchor point layer, or

[0039] S130: Disposing a device on a side of the anchor layer away from the substrate.

[0041] Specifically, the device can be various forms of chips or dustproof structures, etc., when the device is transferred to the transfer belt

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com