4D printing device and method for bionic functional structure

A printing device and 4D technology, applied in the field of printing, can solve the problems such as the inability to realize the integrated and rapid preparation of bionic variant driving bodies, and achieve the effects of shortening the preparation production cycle, wide application range, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

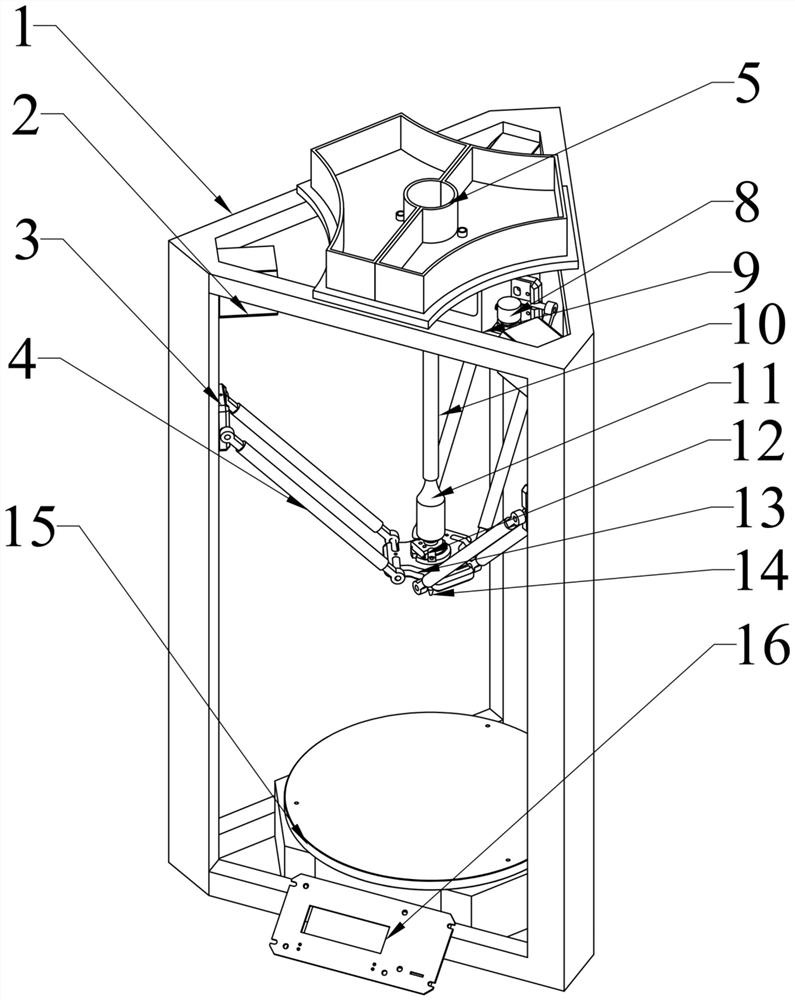

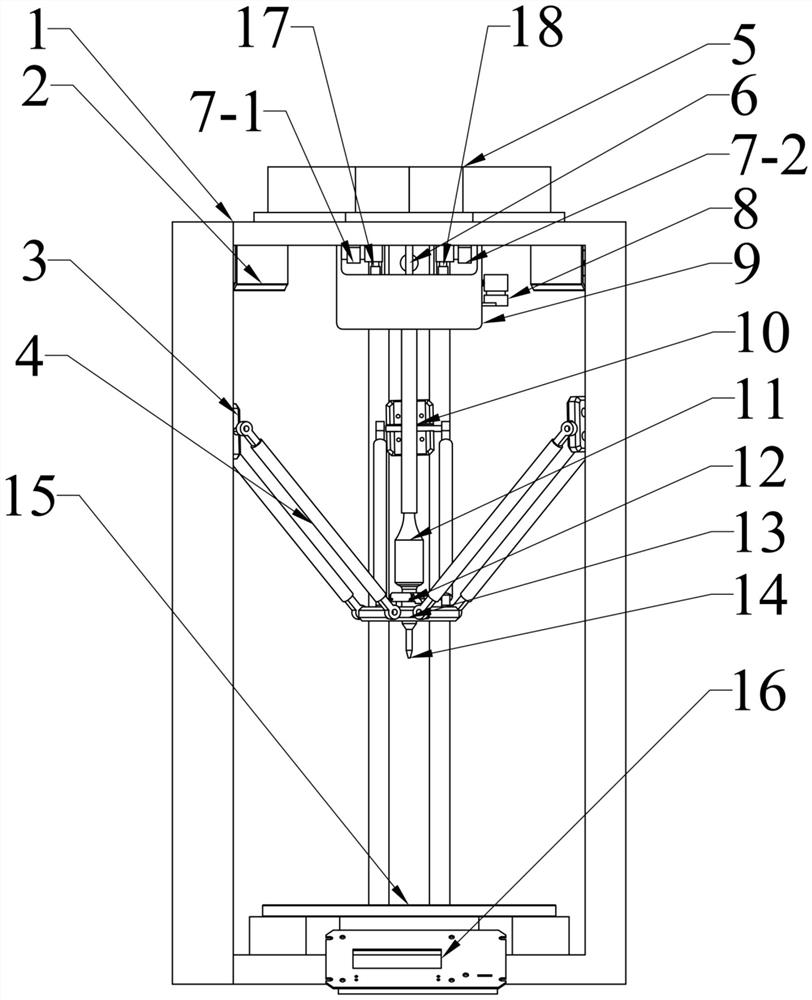

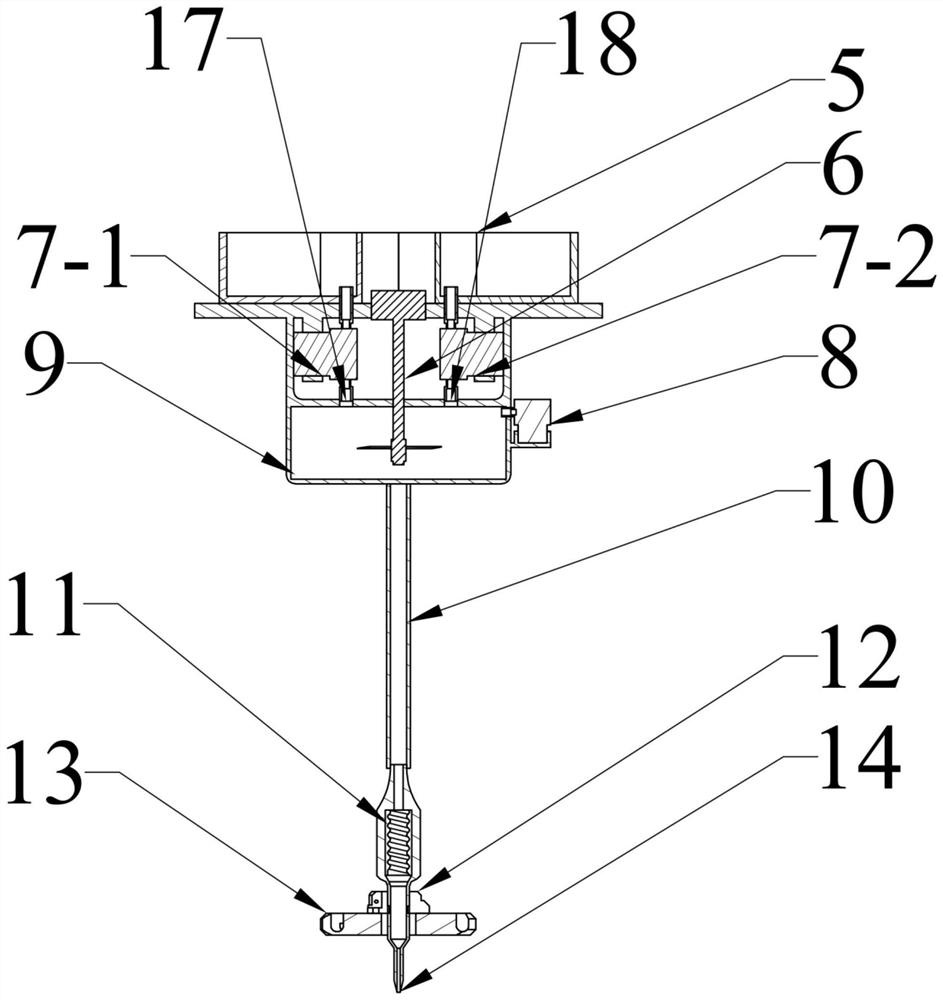

[0061] Such as Figure 1-3 The shown 4D printing device includes: a parallel arm printing mechanism, a material storage unit, a feeding unit, a mixing unit, a printing unit and a curing unit; the storage unit, the feeding unit, the mixing unit, the printing unit and the curing unit are all set On the parallel arm printing mechanism;

[0062] The material storage unit includes a two-component material storage box 5, and the two-component material storage box 5 includes two areas for independently storing the first component and the second component;

[0063] The feeding unit includes a first liquid inlet pipe, a second liquid inlet pipe, a first peristaltic pump 7-1 and a second peristaltic pump 7-2;

[0064] The first liquid inlet pipe includes a first liquid inlet end 17 and a first fluid pipe (not shown in the figure), the head of the first liquid inlet end 17 is placed in the first group of partitions, and the tail part is connected to the first group of sections via the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com