Portable pressure test pump

A pressure test pump and portable technology, applied in the field of portable pressure test pumps, can solve problems such as the lag of safety inspection technical means, achieve good social benefits and economic value, be easy to carry, and avoid the effects of excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

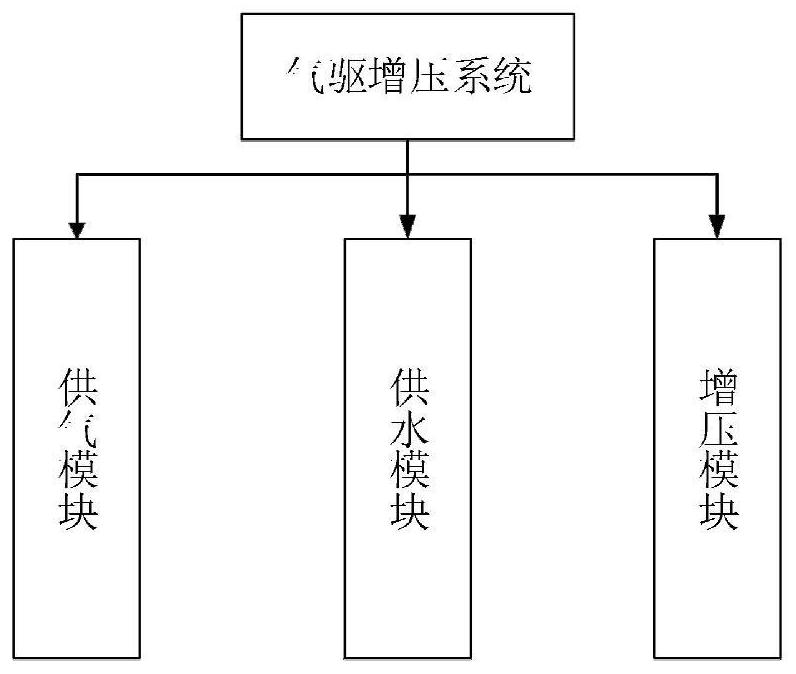

Method used

Image

Examples

no. 1 example

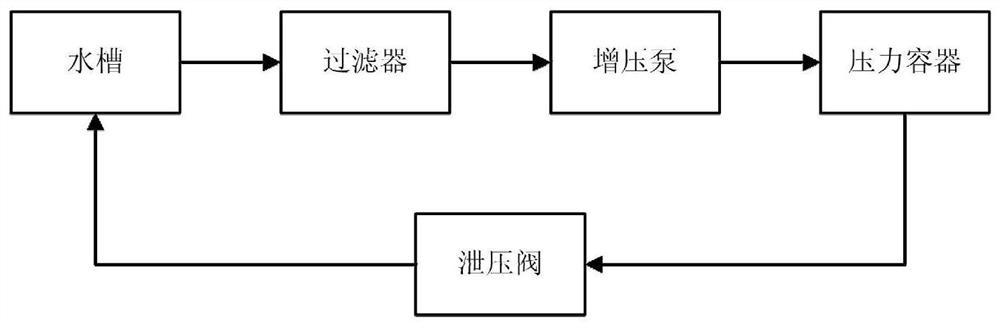

[0042] A portable pressure test pump, comprising an electronic scale, a water tank is fixedly connected to the top of the electronic scale, a supercharger is movably connected inside the water tank, and a first pressure gauge is fixedly connected to one side of the supercharger. A first manual switch, a throttle valve, and a solenoid valve are fixedly installed sequentially between the supercharger and the pressure gauge, and a second manual switch is fixedly connected to one side of the solenoid valve, and the second manual switch One end of the relay is fixedly connected with a relay and a timer in turn, and a pressure sensor is movably connected to one side of the relay. The solenoid valve, timer and pressure sensor belong to the pressure detection system, and one end of the pressure sensor is fixedly connected with an intelligent digital display meter. , one end of the electromagnetic valve is fixedly connected to a computer, and the control system is composed of the pressu...

no. 2 example

[0044] Portable pressure vessel safety inspection device solid model and physical picture Figure 7 shown. The shape, size, layout, operation method, etc. are the same as the actual equipment. Simplify the structure and processing technology under the premise of satisfying various operations.

[0045] 3. The third embodiment:

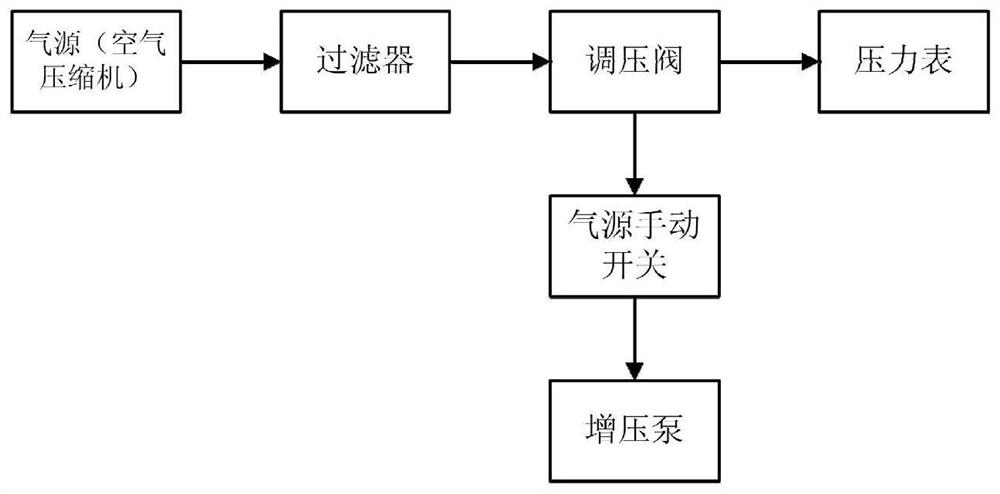

[0046] Such as Figure 9 As shown, when the equipment starts to work, turn on the power switch and gas manual switch, about 0.8MPa of pure air enters the pressurized cylinder through the air circuit, and obtains a high-pressure liquid output of up to about 80MPa after boosting. By adjusting the throttle valve to change the gas flow and then change the liquid flow, to achieve the purpose of changing the pressure test speed. The first pressure gauge and the second pressure gauge display driving gas and test pressure respectively. The pressure sensor is used to detect the experimental pressure. When it reaches the preset value, it will send a signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com