A heat-transfer-enhanced low-resistance solar flat panel collector

A technology of solar panels and enhanced heat transfer, which is applied to solar collectors, solar collector safety, solar collector heat insulation, etc., can solve problems such as inability to transmit solar energy, reduce dirt deposition, increase turbulence, Effect of increasing turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

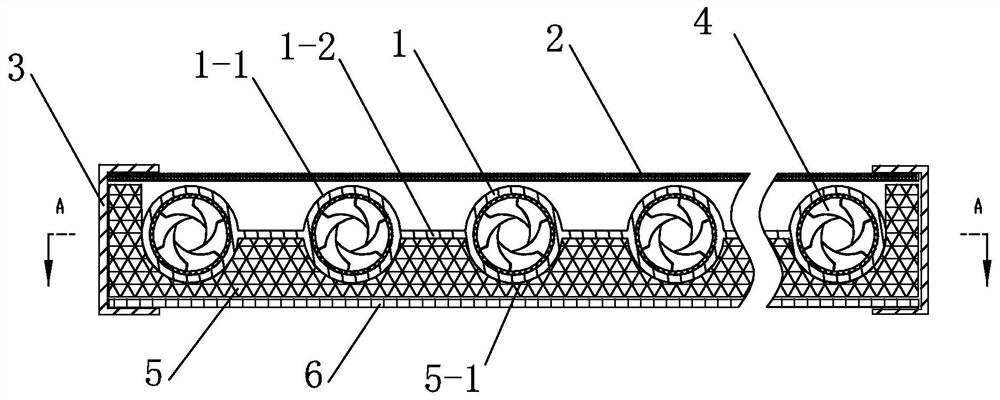

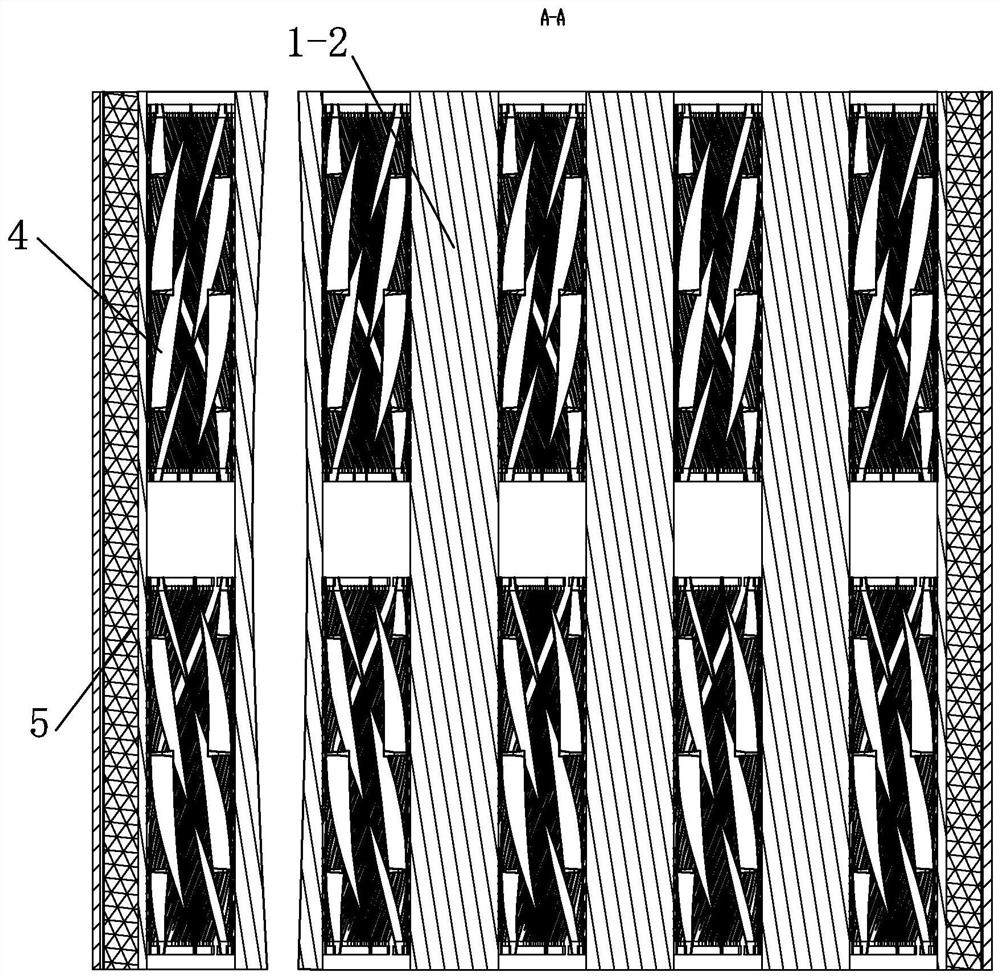

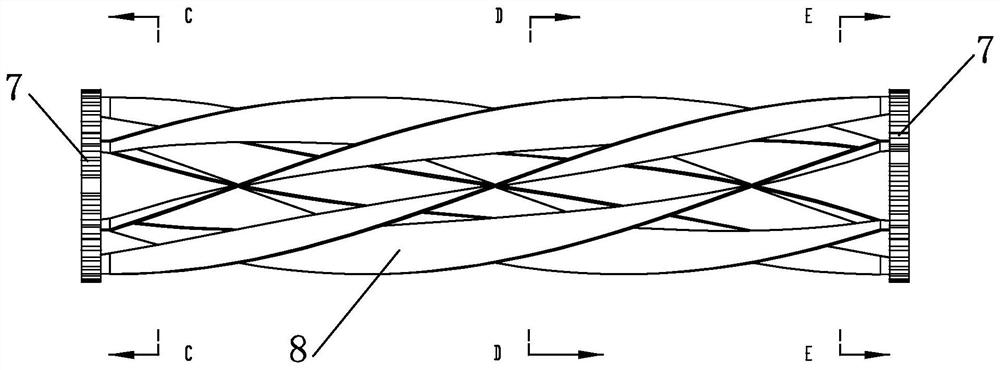

[0013] Specific implementation mode one: combine Figure 1 to Figure 13 Describe this embodiment, a heat transfer-enhanced low-resistance solar flat panel collector of this embodiment, which includes a heat absorber 1, a transparent cover plate 2, a frame 3, at least one spoiler 4, an insulating material 5 and a back plate 6, the heat absorber 1 includes multiple sets of circular tubes 1-1 and multiple heat absorbing plates 1-2, multiple sets of circular tubes 1-1 are arranged in parallel, and an absorber is passed between two adjacent sets of circular tubes 1-1 The heat plate 1-2 is connected; the thermal insulation material 5 is installed on the back plate 6, the heat absorber 1 is installed on the thermal insulation material 5, and at least one spoiler 4 is installed in each group of circular tubes 1-1, and the same group of circular tubes The direction of rotation of the two adjacent turbulence devices 4 in the tube 1-1 is opposite. On the transparent cover plate 2 and th...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the upper end surface of the thermal insulation material 5 of this embodiment is provided with a plurality of arc-shaped grooves 5-1 at equal intervals. With such arrangement, it is convenient to embed multiple sets of circular tubes 1-1 into the arc-shaped grooves 5-1, and the heat-absorbing plate 1-2 can be placed between two connected arc-shaped grooves 5-1. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 7 The present embodiment will be described. The chainring 7 of this embodiment is an annular chainring with notches. Such setting prevents its endothermic expansion from extruding the circular tube flow path. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com