Alcoholysis-resistant reinforced PA6T material and preparation method thereof

An alcoholysis-resistant and fiber-reinforced technology is applied in the field of plastic materials for engines to achieve the effect of improving cohesion and improving industrial practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

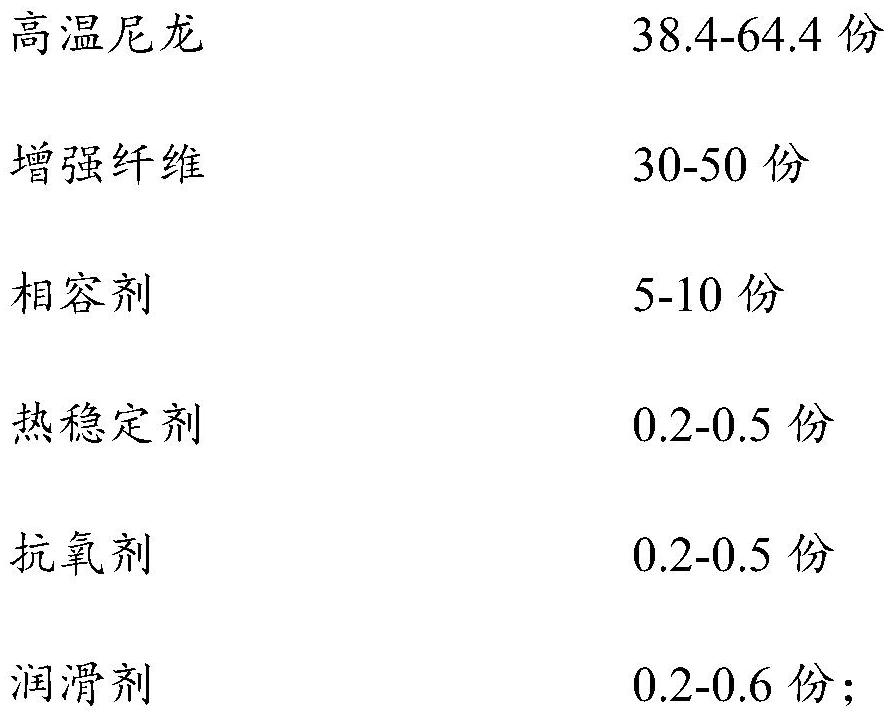

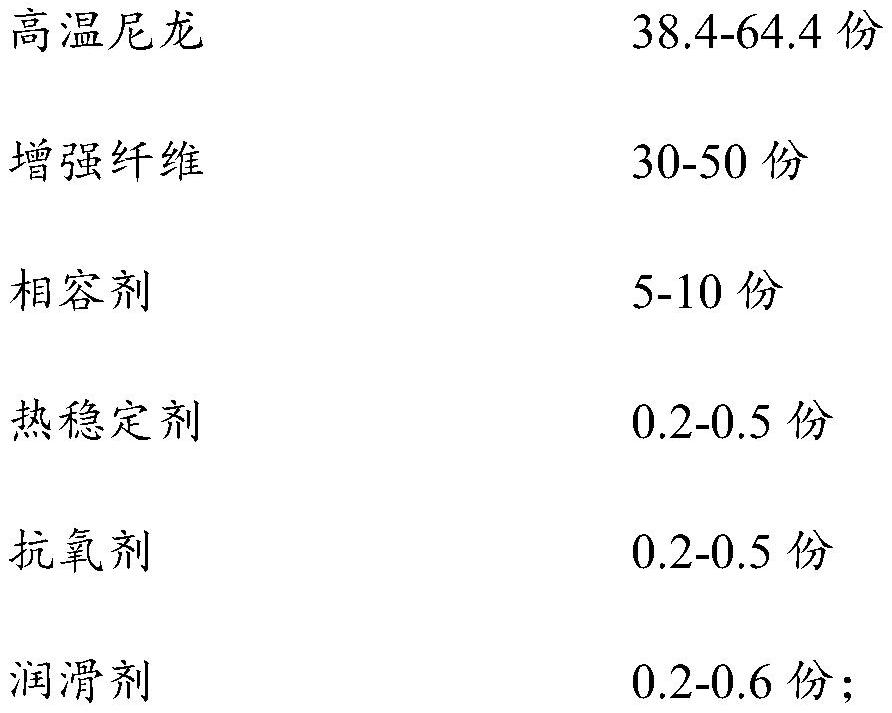

Method used

Image

Examples

Embodiment Construction

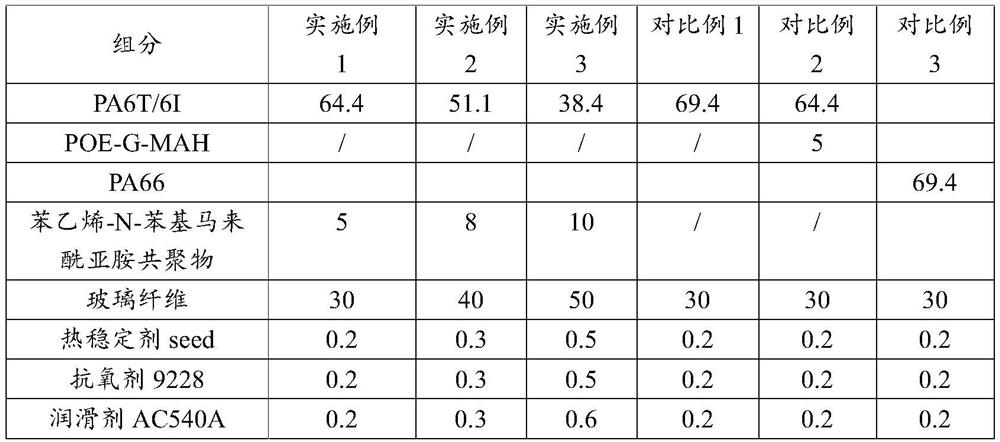

[0020] During the preparation of the following examples or comparative examples, the high-temperature nylon, compatibilizer, heat stabilizer, antioxidant, and lubricant are weighed in the following table 1 and mixed uniformly in a low-speed mixer; subsequently, the premixed The material is added to the twin-screw extruder, and the reinforcing fiber is fed from the side according to the mass ratio. A twin-screw extruder with a medium-strength screw is used, and the length-to-diameter ratio is 40-44:1. 350-500r / min; Among them, the diameter of the reinforcing fiber is 11 microns, the chopped length is 3-4.5mm, and it is quantitatively fed from the fifth section of the barrel by the weight loss metering device.

[0021] Table 1 embodiment 1~3 and comparative example 1~3 batching list

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com