Intelligent hydrogel robot capable of cruising and collecting plastic pollutants on water surface and preparation method of robot

A robot and hydrogel technology, applied in the field of robots, can solve the problems of high salvage cost, dangerous salvage personnel, low efficiency, etc., and achieve the effects of improving cleaning efficiency and safety, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention provides a preparation method for the intelligent hydrogel robot described in the above technical solution, comprising the following steps:

[0022] Mix hydroxyethyl methacrylate, acrylic acid, cross-linking agent, and photoinitiator to form a precursor solution, and then irradiate to obtain an intelligent hydrogel robot that can cruise and collect plastic pollutants on the water surface.

[0023] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0024] The invention mixes hydroxyethyl methacrylate, acrylic acid, a crosslinking agent and a photoinitiator to form a precursor solution. In the present invention, the crosslinking agent is preferably ethylene glycol dimethacrylate, and the photoinitiator is preferably 2-hydroxy-2-methylpropiophenone. In the present invention, the volume ratio of the hydroxyethyl methacrylate, acrylic aci...

Embodiment 1

[0031] Preparation of smart hydrogel precursor: mix hydroxyethyl methacrylate and acrylic acid at a volume ratio of 2:1, and then add cross-linking agent ethylene glycol dimethacrylate, the volume of which and hydroxyethyl methacrylate The ratio is 1:10; then add photoinitiator 2-hydroxy-2-methylpropiophenone, its volume ratio to hydroxyethyl methacrylate is 1:2, after the above liquid is mixed evenly, high-purity nitrogen gas is introduced into the shading After 5 minutes, the prepared precursor solution was obtained.

[0032] Mold making: Use AutoCAD software to model the mold in 3D, and save the modeling file in dwg. format; import the modeling file in dwg. format into the laser cutting machine, laser cut the acrylic sheet, and make an acrylic punch, and the protrusion is a cylinder shape, 1 cm in diameter, and 3 mm in height; on the acrylic punch, use the PDMS molding process to manufacture a PDMS mold.

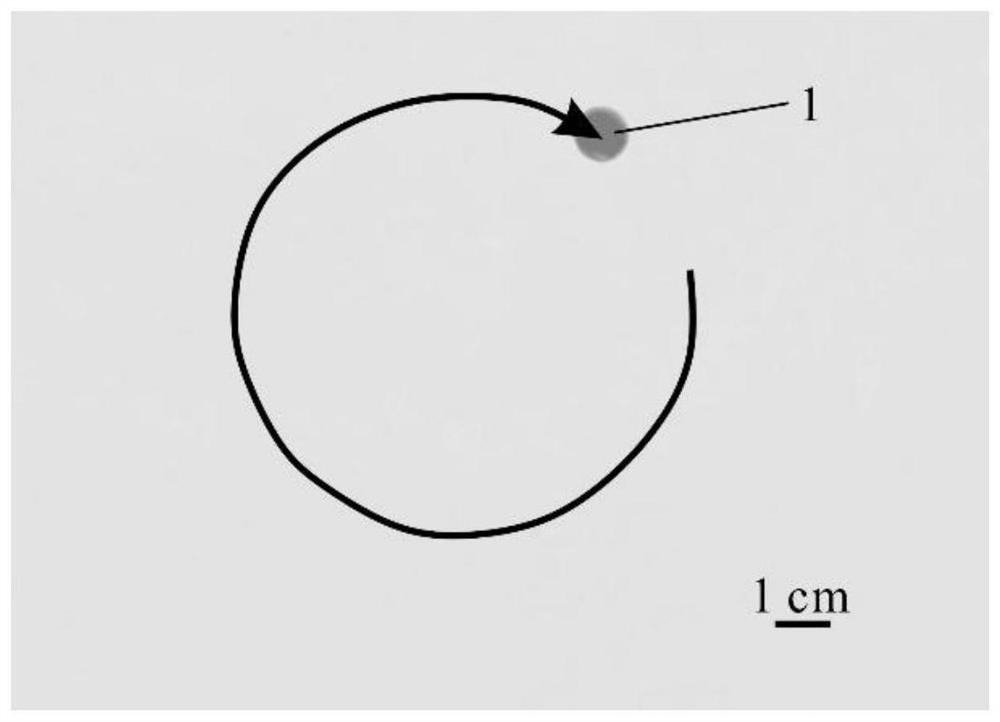

[0033] Fabrication of the intelligent hydrogel robot: inject the co...

Embodiment 2

[0036] According to the scheme described in Example 1, the only difference is that the volume ratio of hydroxyethyl methacrylate to acrylic acid is 1:1, and the volume ratio of the remaining liquids remains unchanged. The volume ratio of hydroxyethyl methacrylate is still 1:10; the volume ratio of photoinitiator 2-hydroxyl-2-methylpropiophenone and hydroxyethyl methacrylate is still 1:2.

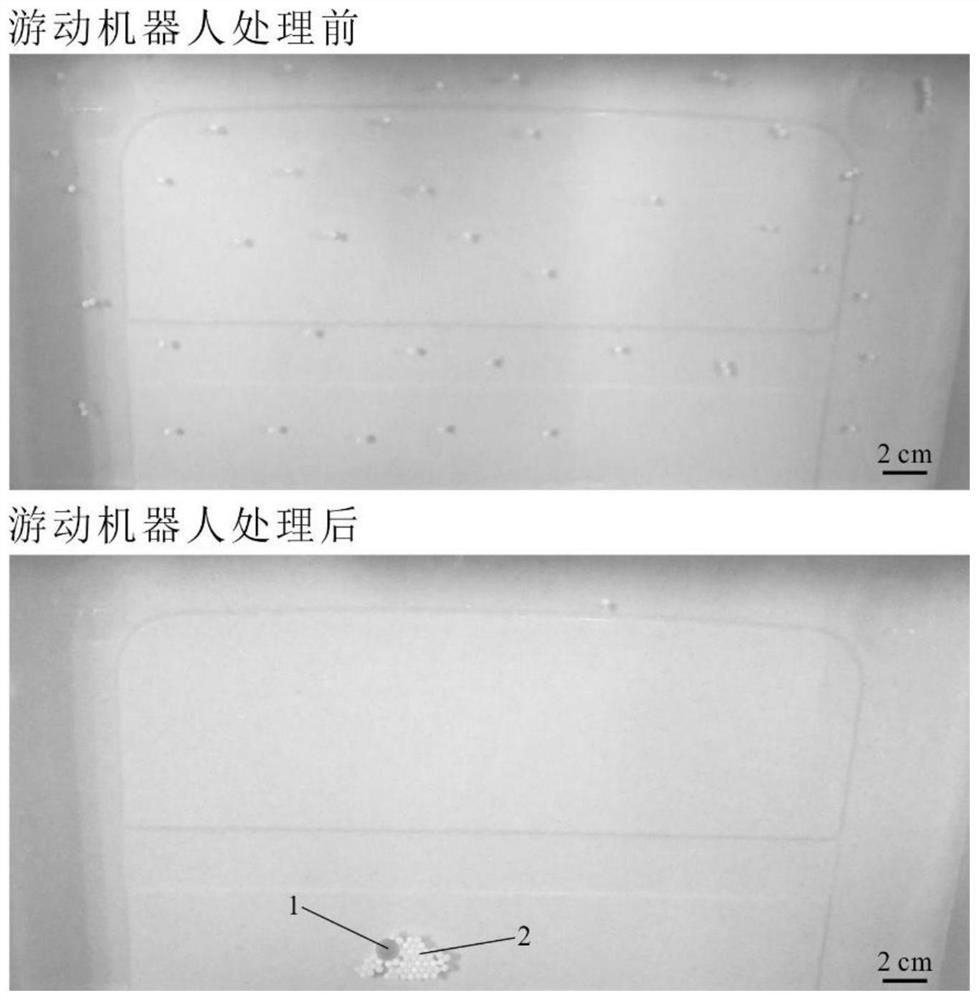

[0037]According to the scheme described in Example 1, the swimming robot that moves autonomously on the water surface in Example 2 is verified. The results show that the intelligent hydrogel robot in Example 2 can also move autonomously after being released to the water surface, and it is released to the point where there is plastic pollution. The water surface of objects can also move autonomously and collect plastic pollutants.

[0038] It can be seen from the above embodiments that the intelligent hydrogel robot provided by the present invention can be used to collect plastic pollutants c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com