High-efficiency wastewater aeration system for water supply and drainage and aeration process

An aeration system, water supply and drainage technology, applied in the field of high-efficiency water supply and drainage wastewater aeration system and aeration process, can solve the problems of uncontrollable, affecting work, unable to filter wastewater, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

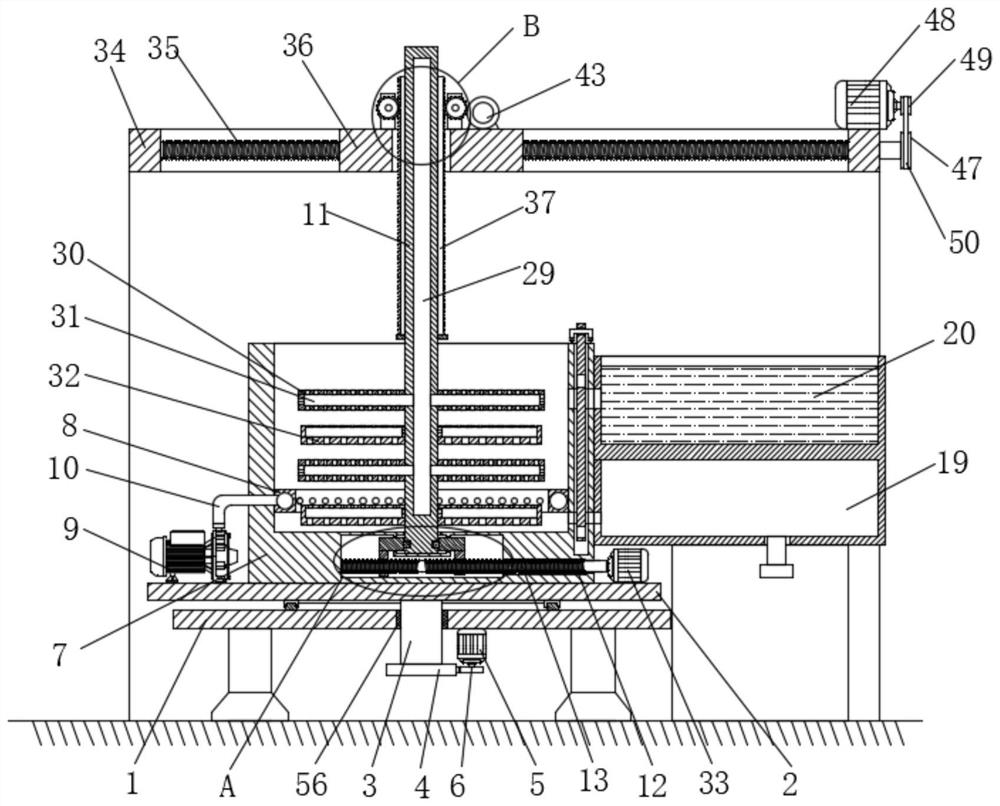

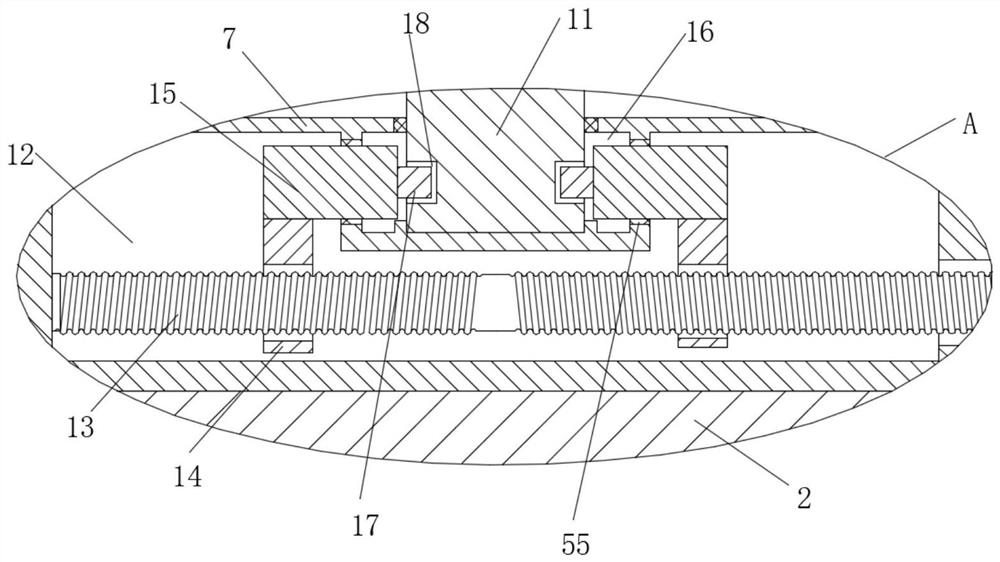

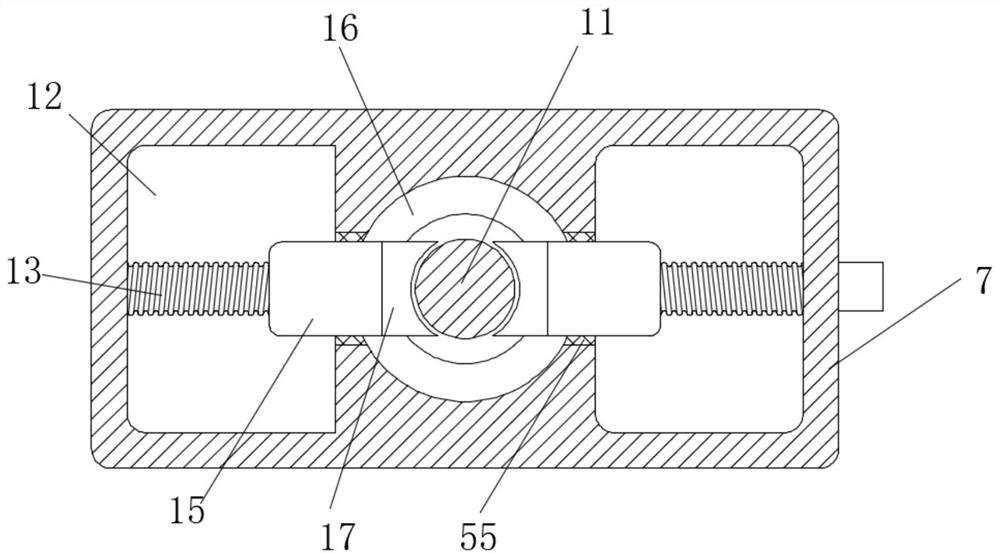

[0050] refer to Figure 1-12 , a high-efficiency wastewater aeration system for water supply and drainage, comprising an aeration tank 7 and a water storage tank 20, the bottom of the aeration tank 7 is fixedly connected with a rotating platform 2, and the bottom of the aeration tank 7 is provided with a device for driving the aeration tank 7 The rotating drive assembly, the inner wall of the aeration barrel 7 is fixedly connected with the aeration tube 8, the top side of the turntable 2 is fixedly connected with the first air pump 9, and the fixed sleeve of the air outlet of the first air pump 9 is provided with a first soft Tube 10, one end of the first hose 10 runs through the aeration tank 7 and extends into the aeration tube 8, the bottom inner wall of the aeration tank 7 is provided with a rotating groove 16, and the bottom inner wall of the rotating tank 16 is rotatably connected with a stirring rod 11 , the aeration tank 7 is provided with a control assembly for limiti...

Embodiment 2

[0065] Embodiment two: if Figure 13 As shown in -15, a high-efficiency wastewater aeration system for water supply and drainage, the difference between this embodiment and Embodiment 1 is that the outer wall fixing sleeve of the stirring rod 11 is provided with a plurality of fixing plates 51, and both sides of the fixing plates 51 are A card slot 52 is provided, and both sides of the fixing plate 51 are fixedly connected with screw rods 53, and the ends of the two screw rods 53 far away from the stirring rod 11 run through the activated carbon placement frame 32, and the outer walls of the two screw rods 53 are screwed with second nuts 54 The sides of the two activated carbon placement frames 32 close to the stirring rod 11 both extend into the slot 52 .

[0066] However, as is well known to those skilled in the art, the work of the first rotating motor 5, the first air pump 9, the second rotating motor 33, the second air pump 45, the first driving motor 43, the second drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com