An automatic slot milling device applied to the production of smart cards and its application method

A slot milling device and smart card technology, which is applied in the direction of feeding device, positioning device, milling machine equipment, etc., can solve the problems of lower production efficiency, time-consuming and labor-intensive, inconvenient smart card slot milling operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

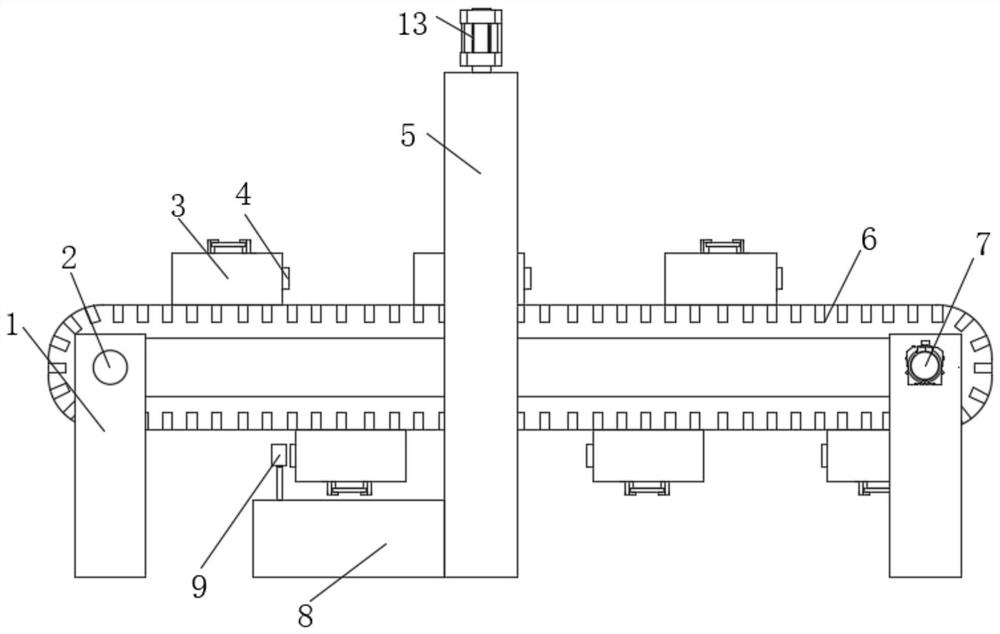

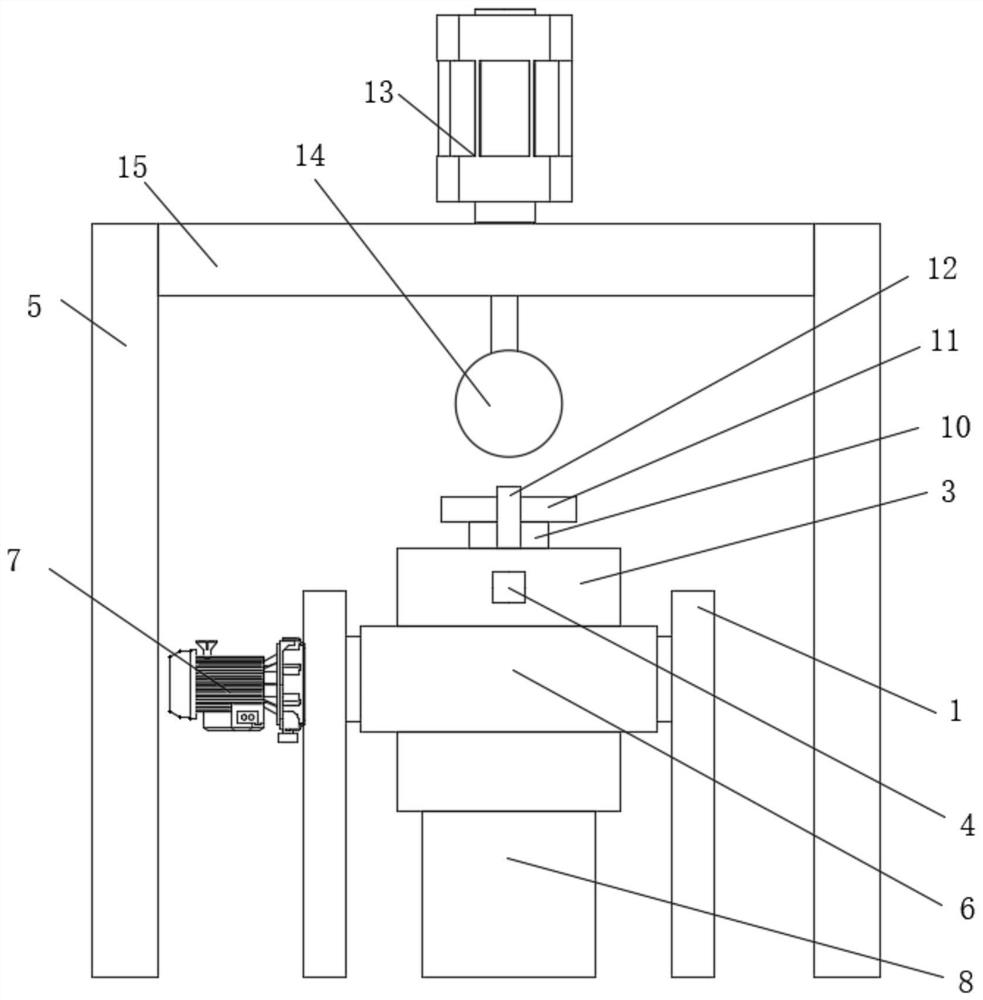

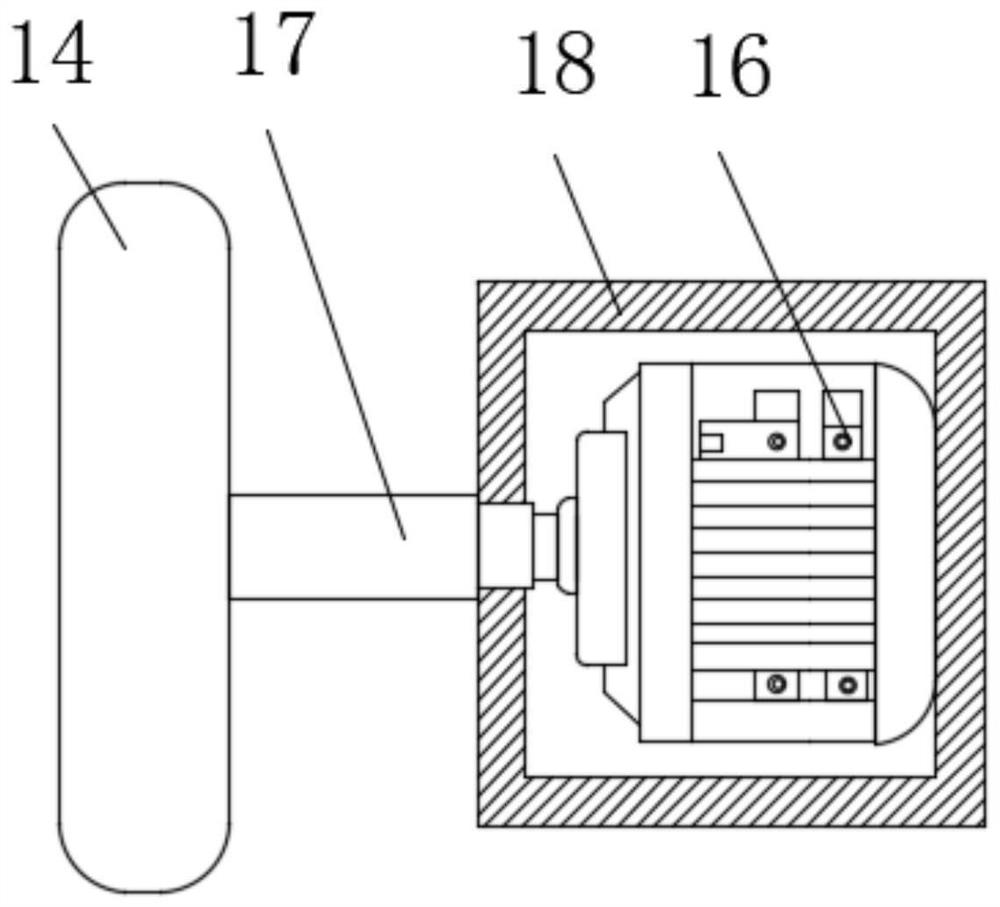

[0039] Embodiment one: if Figure 1-8 As shown, an automatic slot milling device applied to the production of smart cards includes a smart card body 11 and four fixed columns 1 that are symmetrical in pairs. Roller 2, the outer walls of the two rotating rollers 2 are covered with the same conveyor belt 6, the outer wall of the conveyor belt 6 is fixedly connected with a plurality of storage boxes 3, and one side of one fixed column 1 is fixedly connected with the first motor 7, the first motor The output shaft of 7 runs through the fixed column 1 and is fixedly connected with the rotating roller 2. The fixing assembly for fixing the smart card body 11 is arranged inside the storage box 3, and side plates 5 are arranged on both sides of the conveyor belt 6, and the two side plates 5 are connected to each other. The top of the adjacent side is fixedly connected with the same top plate 15, and the bottom of the top plate 15 is fixedly connected with a milling assembly for milling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com