Electrochemical biofilm filter assembly, application thereof and reactor

A filter component and biofilm technology, applied in the direction of electrochemical biocombination treatment, chemical instruments and methods, biological treatment devices, etc., can solve the problem that EAOPs are difficult to effectively mineralize organic pollutants, are affected by water quality in specific locations, and accumulate intermediate products and other problems, to achieve the effect of compact structure, improved degradation effect, and enhanced degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

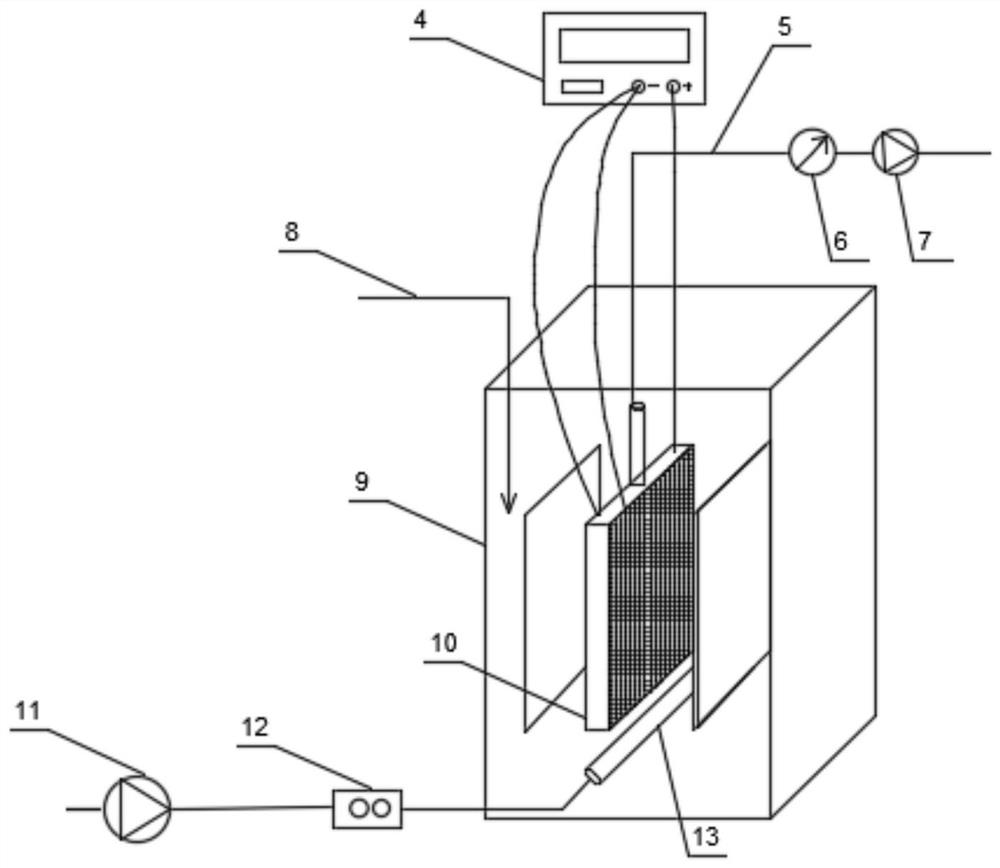

[0027] Such as Figure 1-2 As shown, it is an electrochemical biofilm filtration assembly provided in this embodiment, which is used to strengthen the degradation of intermediate products in the sewage treatment process, including the first titanium mesh cathode 1-1 as the cathode, and the titanium-based tin as the anode Antimony anode 3, the second titanium mesh cathode 1-2 as cathode, water outlet pipe 5, water outlet peristaltic pump 7 arranged outside the reactor shell 9 and connected to the water outlet pipe 5, water inlet pipe 8, voltage stabilizing Power supply 4; the titanium mesh is sheet-shaped, and the first titanium mesh cathode 1-1 and the second titanium mesh cathode 1-2 are respectively placed on both sides of the film frame 2, and are connected to the negative pole of the stabilized power supply, and serve as The substrate for biofilm growth; the membrane frame 2 is filled with an electrochemical biofilm filter assembly 10; the titanium-based tin-antimony elect...

Embodiment 2

[0037] Such as figure 2 Shown is an electrochemical biofilm filtration reactor including the electrochemical biofilm filtration assembly according to Embodiment 1 of the present invention, which also includes a reactor housing 9 .

[0038] The above-mentioned electrochemical biofilm reactor is used to treat simulated surface water containing p-aminobenzenesulfonic acid, and the experimental conditions are set as: influent COD 40mg / L, NH 4 +-N 2mg / L, p-aminobenzenesulfonic acid 10μM, regulated DC power supply voltage of 4.0V, treated water volume of 17.7L / d, and hydraulic retention time of 6.0h. A reactor with no external electric field and other conditions under the same conditions was set as a blank control group. The two reactors were operated continuously for 30 days in the continuous flow mode, and the results showed that the removal rate of COD in the two reactors was >70%, and the removal rate of p-aminobenzenesulfonic acid in the blank group was about 50%, while the ...

Embodiment 3

[0040] Use the above-mentioned electrochemical biofilm reactor to treat simulated surface water containing p-aminobenzenesulfonic acid. The experimental conditions are set as follows: the concentration of influent COD is 40mg / L, 4 + The concentration of -N is 2mg / L, the concentration of p-aminobenzenesulfonic acid is 10μM, the regulated DC power supply voltage is 4.0V, the treated water volume is 17.7L / d, and the hydraulic retention time is 6.0h. Set the anode as a graphite plate and the reactor with the same conditions as the control group. The two reactors were operated continuously in continuous flow mode for 30 days, and the results showed that the removal rate of COD in the two reactors was >70%, and the removal rate of p-aminobenzenesulfonic acid in the control reactor with graphite plate as the anode was about 60% , and the removal rate of p-aminobenzenesulfonic acid can reach more than 80% in the reactor with tin-antimony electrode as the anode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com