3D anti-collision buffer material, preparation method thereof and helmet buffer cushion layer

A cushioning material and anti-collision technology, applied in helmets, chemical instruments and methods, helmet caps, etc., can solve the problems of increased helmet weight, insufficient comfort, unfavorable impact force dispersion and transmission, etc., to achieve broad application prospects, compression resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

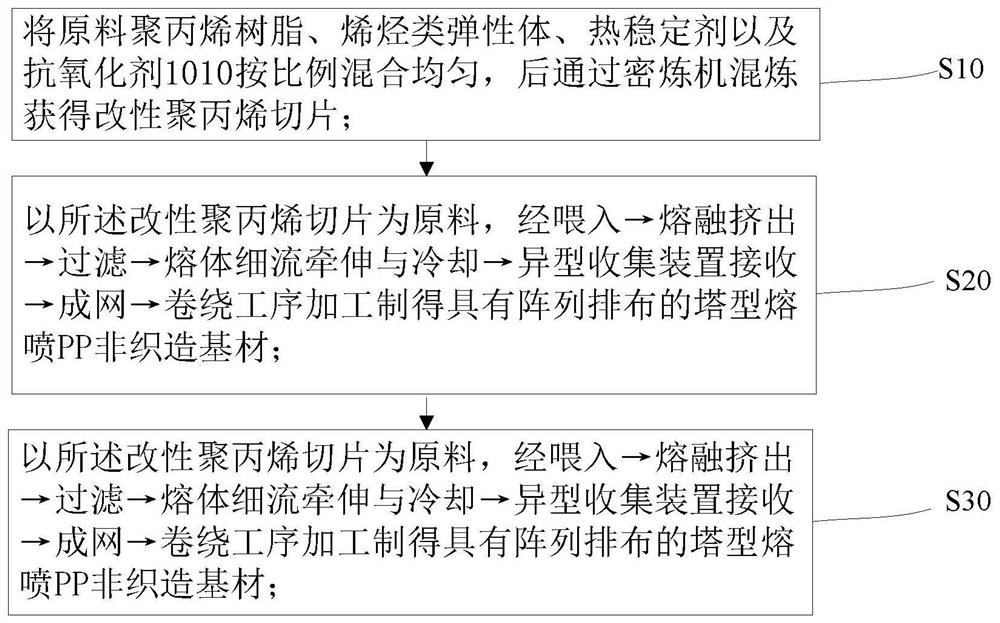

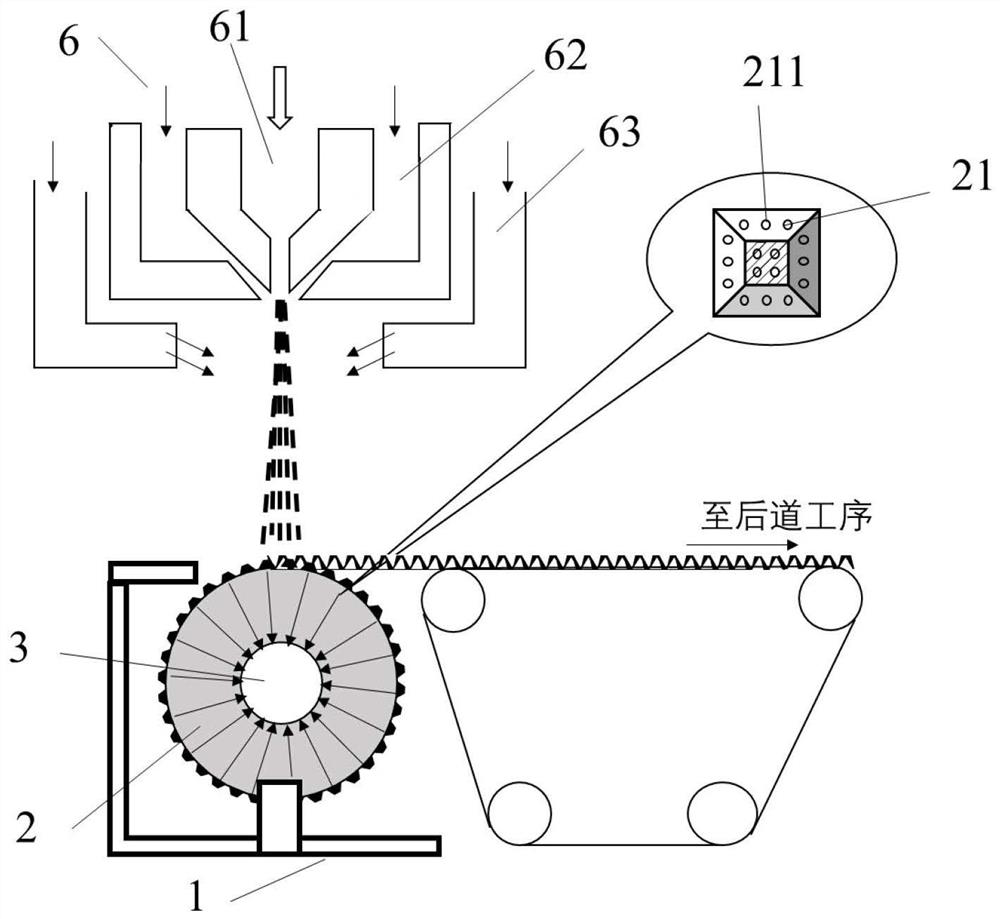

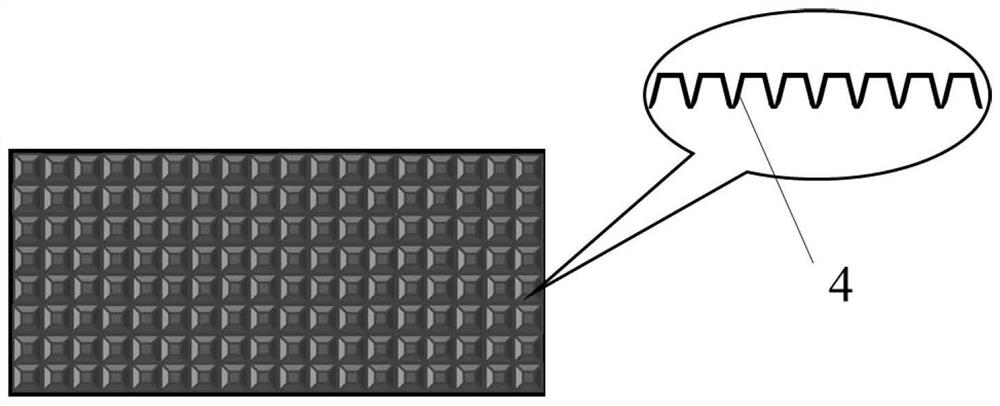

[0027] This embodiment provides a kind of preparation method of 3D anti-collision cushioning material, such as figure 1 As shown, it includes the following steps: S10 mixes the raw material polypropylene resin, olefinic elastomer, heat stabilizer and antioxidant 1010 uniformly in proportion, and then kneads with an internal mixer to obtain modified polypropylene chips. S20 uses the modified polypropylene slices as raw materials, and is processed through feeding→melt extrusion→filtering→melt trickle drawing and cooling→special-shaped collecting device receiving→netting→winding process to produce a plastic film with an array arrangement. Tower type meltblown PP nonwoven substrate4. In S30, at least two layers of the tower-shaped melt-blown PP nonwoven substrate 4 are evenly brushed with adhesive under the action of double rollers and solidified for a period of time to prepare a melt-blown anti-collision buffer material 5 with a three-dimensional structure. The composition of th...

Embodiment 1

[0034] A preparation method for a 3D anti-collision cushioning material, comprising the steps of:

[0035] S10 Mix 55 parts of raw material polypropylene resin, 5 parts of olefinic elastomer, 2 parts of heat stabilizer and 10100.1 parts of antioxidant, and then knead with internal mixer to obtain modified polypropylene chips;

[0036] S20 uses the modified polypropylene slices as raw materials, and is processed through feeding→melt extrusion→filtering→melt trickle drawing and cooling→special-shaped collecting device receiving→netting→winding process to produce a plastic film with an array arrangement. Tower-type melt-blown PP nonwoven substrate; the hot air flow pressure of the suction device is 0.2MPa, the receiving distance is 15cm, and the hot air temperature is 200°C. The web-forming speed is 10m / min, and the thickness of the tower-shaped melt-blown PP nonwoven substrate is 2.4mm.

[0037] In S30, the 12-layer tower-shaped melt-blown PP nonwoven substrate is evenly rolled...

Embodiment 2

[0039] A preparation method for a 3D anti-collision cushioning material, comprising the steps of:

[0040] S10 Mix 65 parts of raw material polypropylene resin, 7 parts of olefinic elastomer, 5 parts of heat stabilizer and 10100.3 parts of antioxidant, and then knead with internal mixer to obtain modified polypropylene chips;

[0041] S20 uses the modified polypropylene slices as raw materials, and is processed through feeding→melt extrusion→filtering→melt trickle drawing and cooling→special-shaped collecting device receiving→netting→winding process to produce a plastic film with an array arrangement. Tower-type melt-blown PP nonwoven substrate; the hot air flow pressure of the suction device is 0.3MPa, the receiving distance is 20cm, and the hot air temperature is 250°C. The web-forming speed is 50 m / min, and the thickness of the tower-shaped melt-blown PP nonwoven substrate is 2.7 mm.

[0042] In S30, the 25-layer tower-shaped melt-blown PP nonwoven substrate is evenly roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powerful | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com