Fast die changing device for building

A construction and mould technology, applied in the field of construction mould quick mould changing device, can solve the problems of low practicability, reduced production efficiency, inconvenient clamping of moulds of different sizes, etc., so as to avoid device instability and improve production efficiency. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

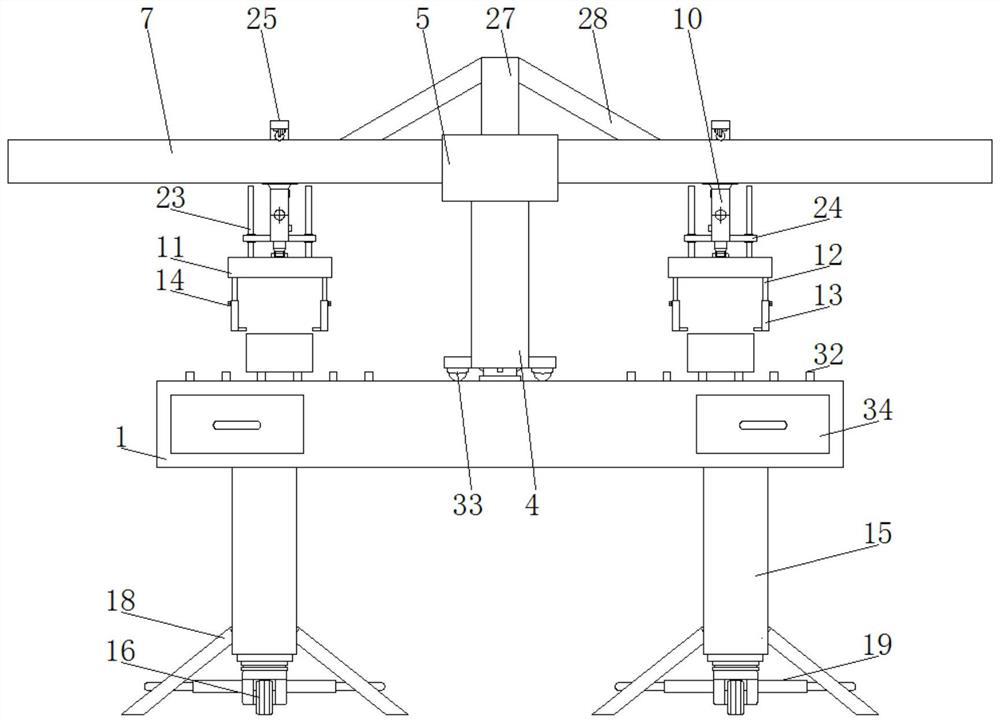

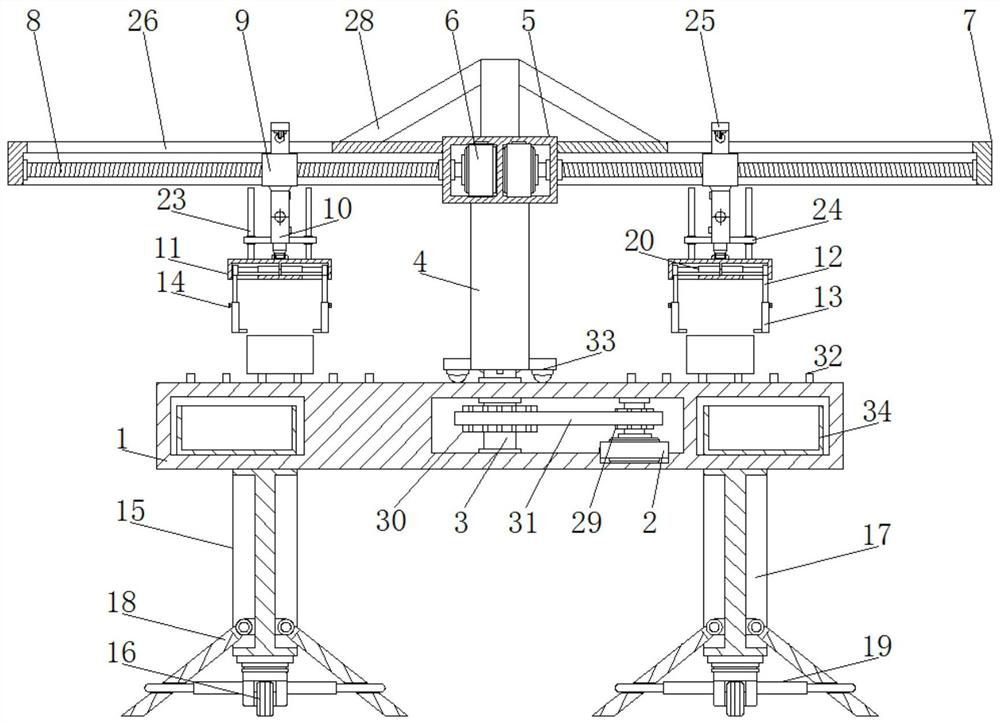

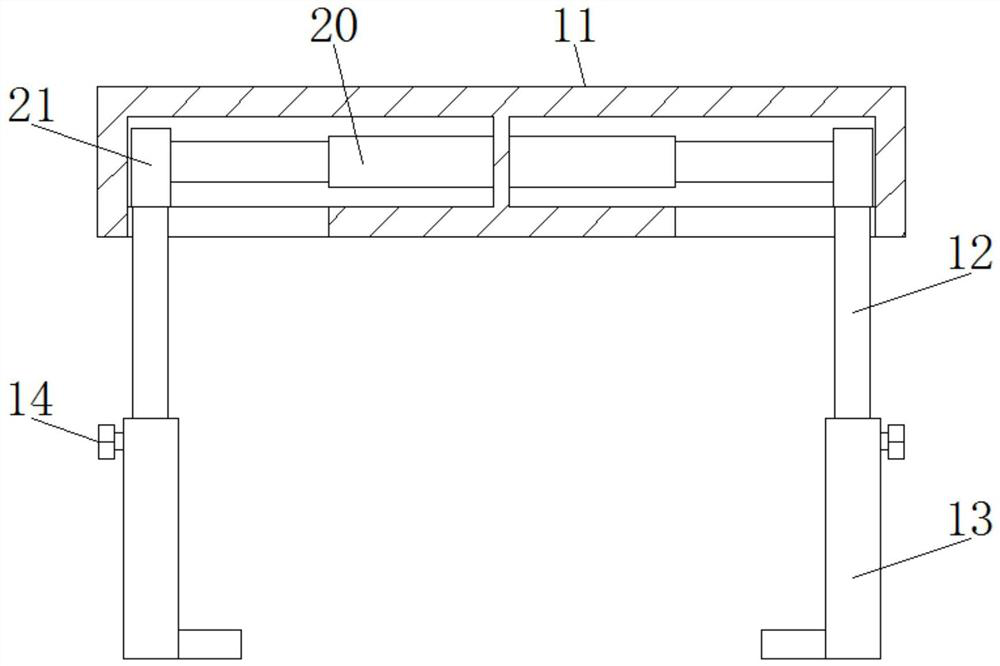

[0019] according to figure 1 , 2 , 3, and 4, the present embodiment provides a quick mold change device for construction molds, including a machine platform 1, and the inside of the machine platform 1 is provided with a rotating shaft 3 driven by a first motor 2, and the rotating shaft 3 The top of the support column 4 is connected to the machine 1 through the bearing, the top of the support column 4 is fixed with the motor box 5, and the second motor 6 is symmetrically arranged inside the motor box 5, and the two sides of the motor box 5 are fixed with support Arm 7, the inner side of the support arm 7 is provided with a screw 8, the output end of the second motor 6 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com