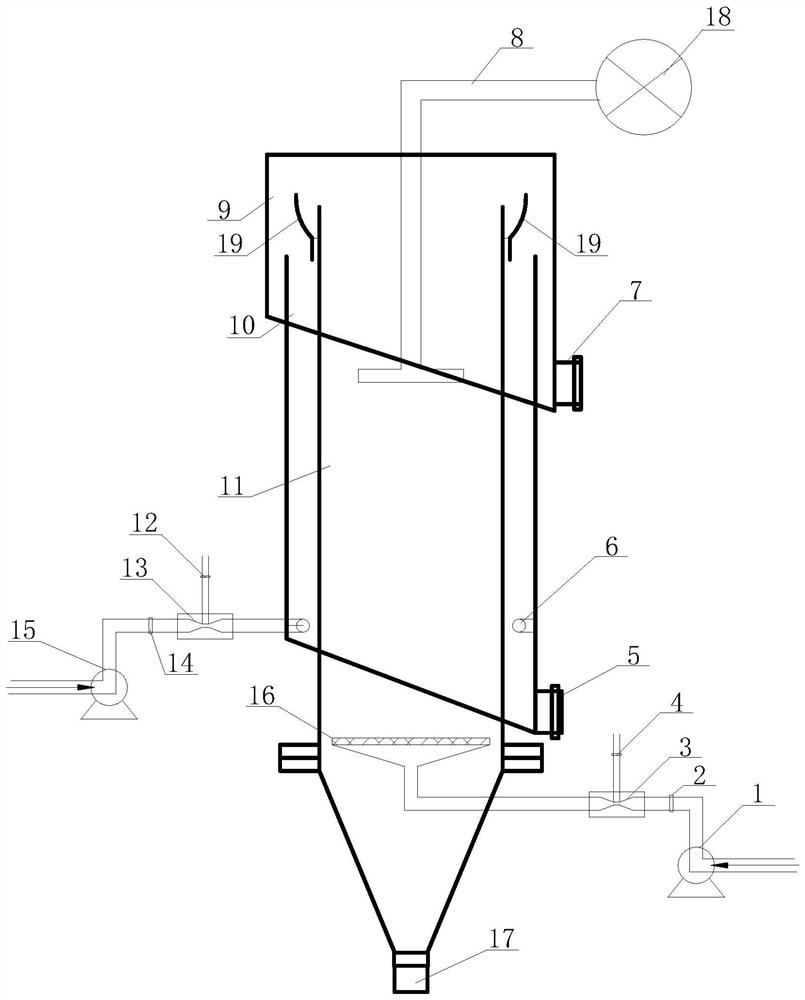

A secondary hydraulic flotation machine and flotation method for mineral coarse particle separation

A technology of coarse particles and flotation machines, applied in flotation, solid separation, etc., can solve the problems of poor adaptability and low sorting efficiency, and achieve the effect of reducing the cost of grinding and floating, reducing the load of grinding and floating, and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a secondary hydraulic flotation method for sorting and discarding tailings of coarse particles, using the above-mentioned secondary hydraulic flotation machine.

[0081] In this embodiment, a certain crystalline graphite ore is used, the fixed carbon content of the raw ore is 14.59%, the distribution rate of +0.150mm graphite flakes in the raw ore reaches 93.21%, and the grinding fineness reaches -0.300mm, which can achieve better monomer solution Leave.

[0082] Step 1: Directly import the 3.00-0.15mm grain size mineral particles into the mixing tank 18, control the slurry concentration to 50%, and add quicklime (1000g / t), kerosene (60g / t) and No. 2 oil (25g / t) in sequence every 3 minutes t) carry out pulping;

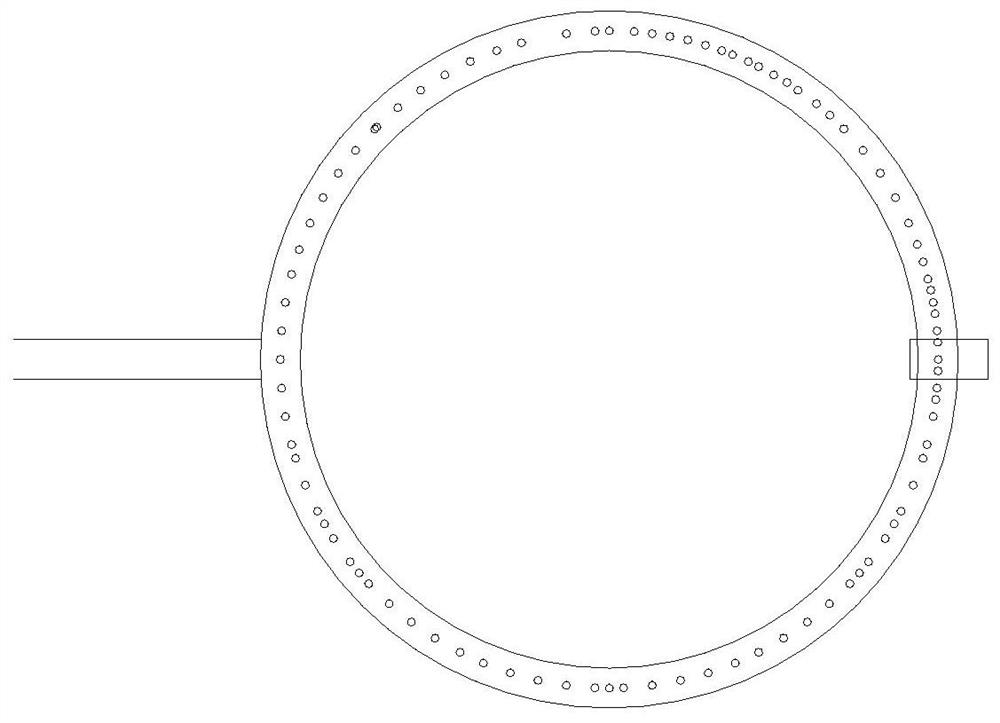

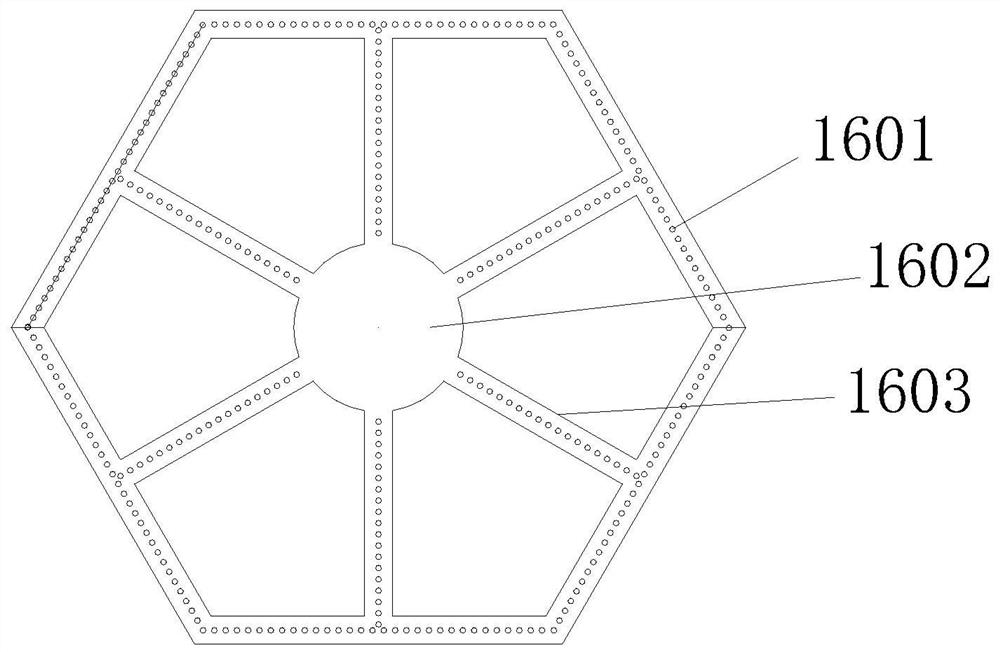

[0083] Step 2: Open the first water inlet valve 2 and the second water inlet valve 14, inject clean water into the first cylinder 11 and the second cylinder 10, until the water in the second cylinder 10 overflows to the third cylinder ...

Embodiment 2

[0087] This embodiment provides a secondary hydraulic flotation method for sorting and discarding tailings of coarse particles, using the above-mentioned secondary hydraulic flotation machine.

[0088] In this embodiment, molybdenite from a certain place is used, the raw ore grade is 0.098%, and the main gangue minerals are quartz, feldspar, mica and chlorite.

[0089] Step 1: Directly import the 3.00-0.15mm grain grade mineral particles into the mixing tank 18, control the slurry concentration to 70%, and add quicklime (900g / t), kerosene (90g / t) and No. 2 oil (40g / t) in sequence every 3 minutes t) carry out pulping;

[0090] Step 2: Open the first water inlet valve 2 and the second water inlet valve 14, inject clean water into the first cylinder 11 and the second cylinder 10, until the water in the second cylinder 10 overflows to the third cylinder stably In the column body 9; open and adjust the first air intake valve 4 and the second air intake valve 12, ventilate in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com