Multi-angle exposure equipment and manufacturing method of electroplated metal wire

A metal wire, electroplating metal technology, applied in microlithography exposure equipment, optomechanical equipment, removal of conductive materials by chemical/electrolytic methods, etc., can solve the problems of high technical strength, difficult to manufacture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] According to an embodiment of the present invention, the present invention uses the prepared metal wire seed layer as a photomask, and simultaneously uses a scattering layer as an auxiliary layer for back exposure, so as to solve the problem of exposure when the metal wire seed layer is used as a photomask. Diffraction problems will occur, and the structure required for exposure to the negative photoresist can be accurately fabricated. The manufacturing process is simple, easy to implement, and low in cost, which greatly improves the yield of the high aspect ratio electroplating process.

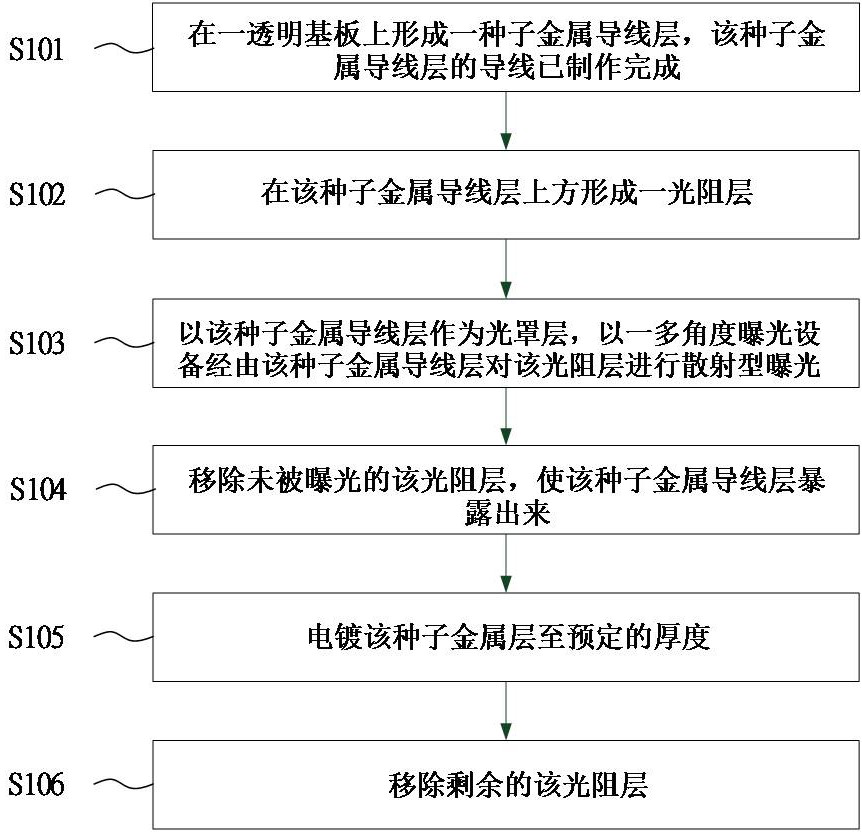

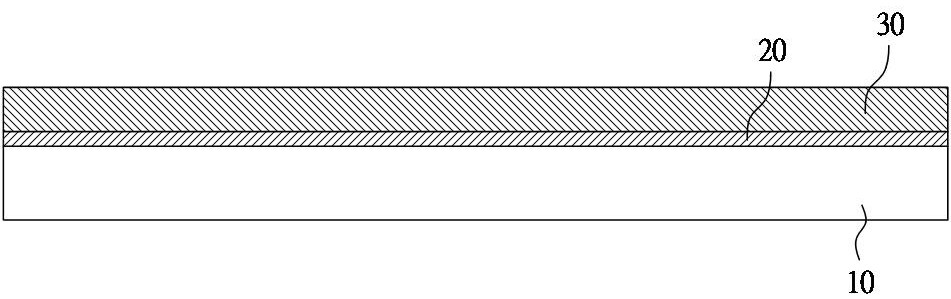

[0035] Please refer to figure 1 , a flow chart of a method for manufacturing an electroplated metal wire disclosed in the present invention, please refer to Figures 2A-2K , Figures 3A-3J An embodiment of the production process, including:

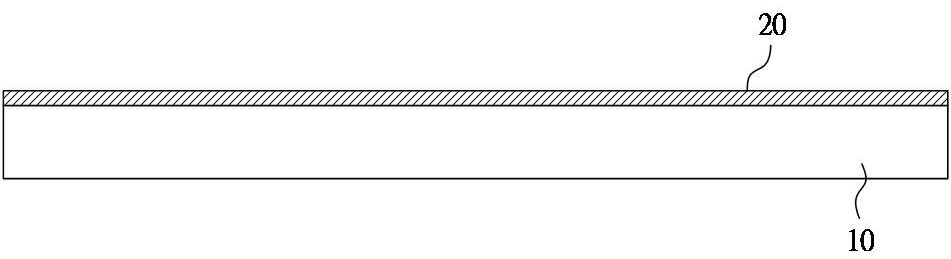

[0036] Step S101 : forming a seed metal wire layer on a transparent substrate, and the wires of the seed metal wire layer have been fabricated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com