Method for preparing antireflection grating

An anti-reflection and grating technology, which is applied in the direction of diffraction grating, optical mechanical equipment, photoplate making process of patterned surface, etc., to achieve the effect of wide application value, clear physical meaning and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

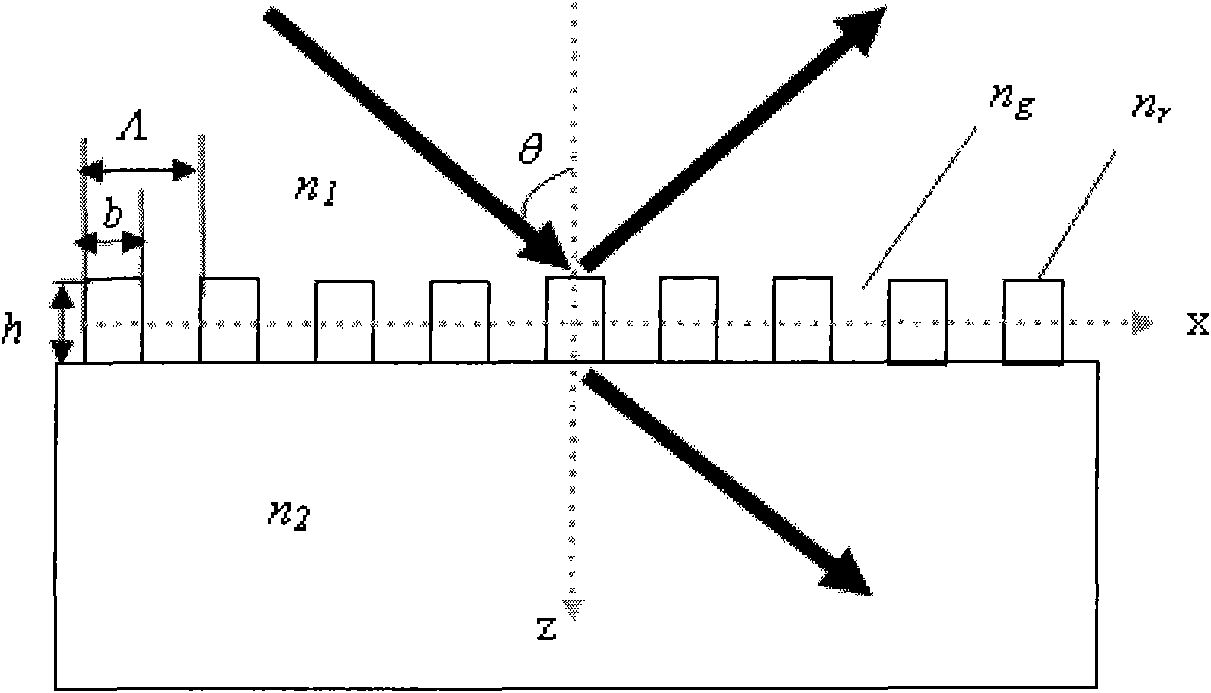

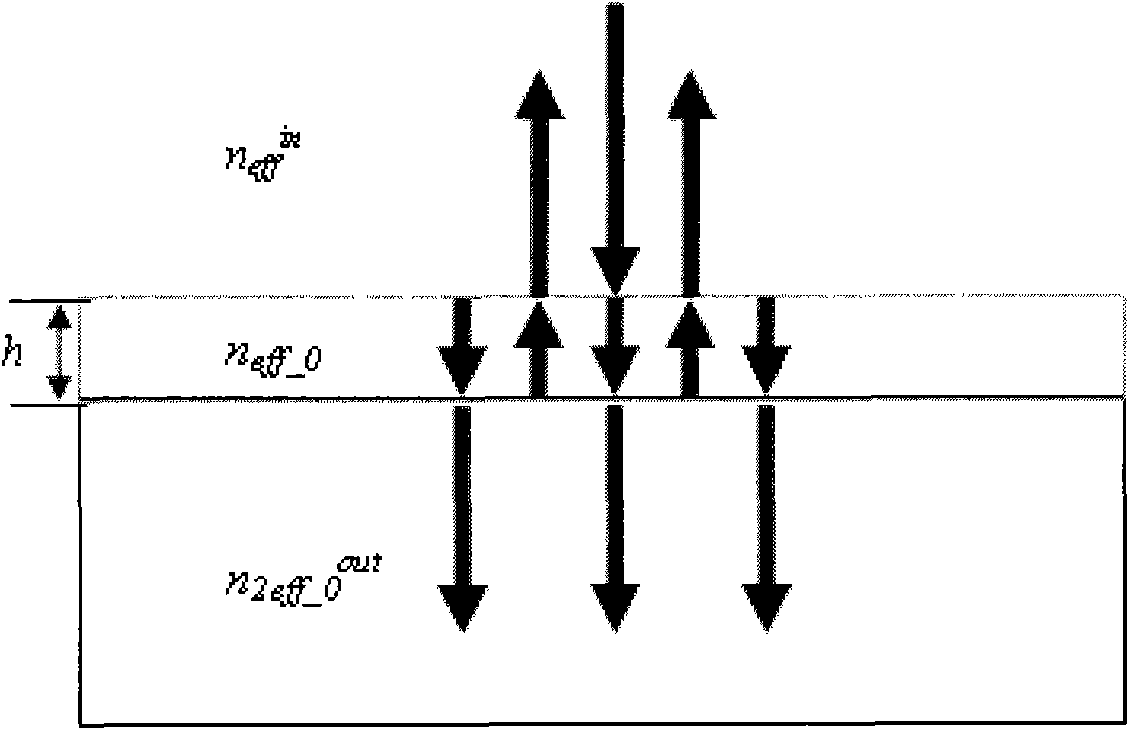

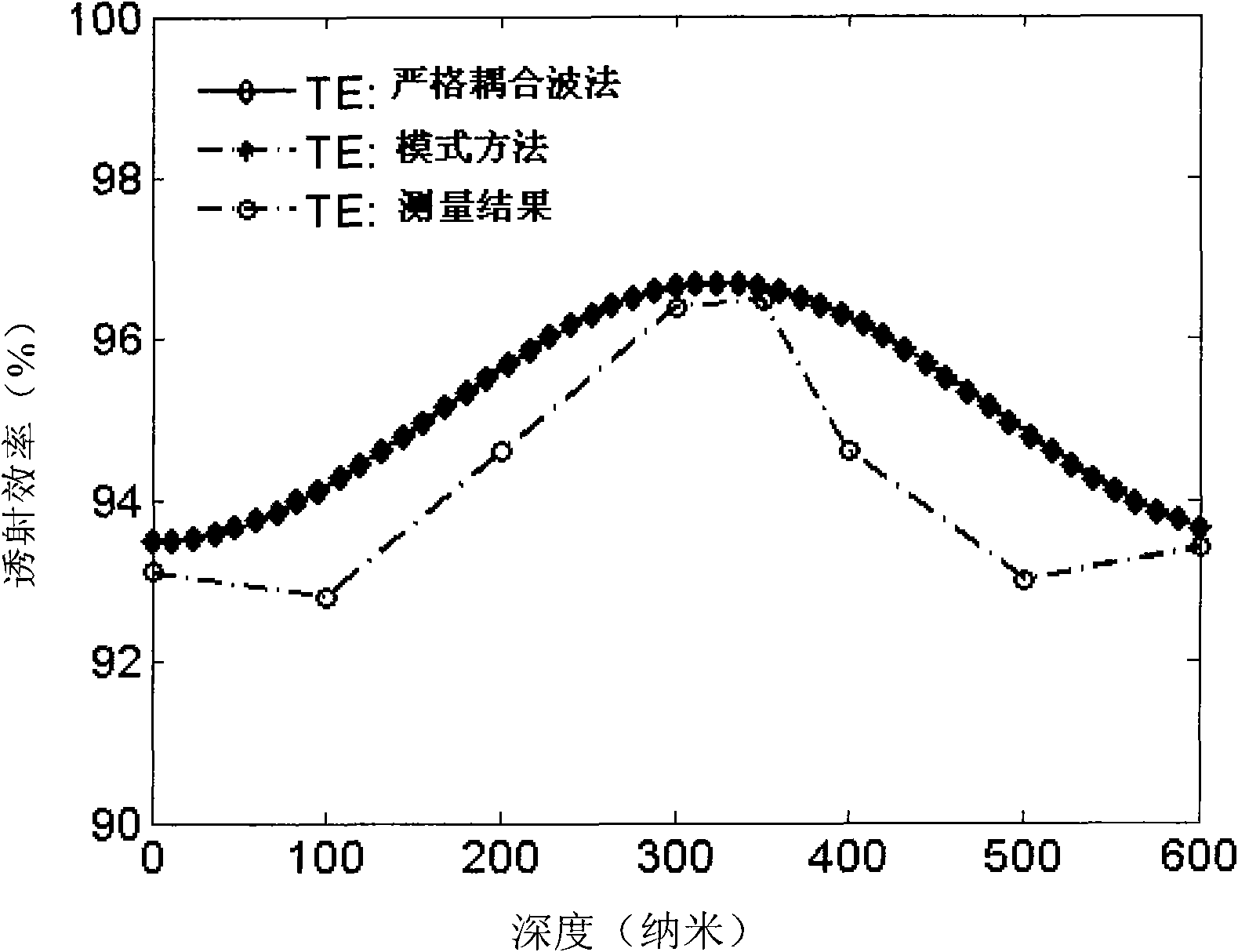

[0032] see first figure 1 and figure 2 , figure 1 It is a schematic diagram of the geometric structure of the anti-reflection grating of the present invention. figure 2 yes figure 1 Schematic diagram of the equivalent structure of an anti-reflection grating. figure 1 In , regions 1 and 2 are homogeneous, which are incident medium and grating substrate material respectively. The vibration direction of the TE polarized incident light corresponding to the electric field vector is perpendicular to the incident plane, and the vibration direction of the TM polarized incident light corresponding to the magnetic field vector is perpendicular to the incident plane. The linearly polarized light wave is incident at a certain angle θ, λ represents the incident wavelength, and Λ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com