Spin precession-type acoustic wave measurement ship-borne device for rock cores

A sound wave measurement and sound wave technology, which is applied in the field of rock core screw-in sound wave measurement ship-borne devices, can solve the problems of poor pressure resistance and stability of the sound wave receiver, insufficient measurement accuracy, and inconvenient operation of the components. Achieve the effect of solving pressure resistance and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

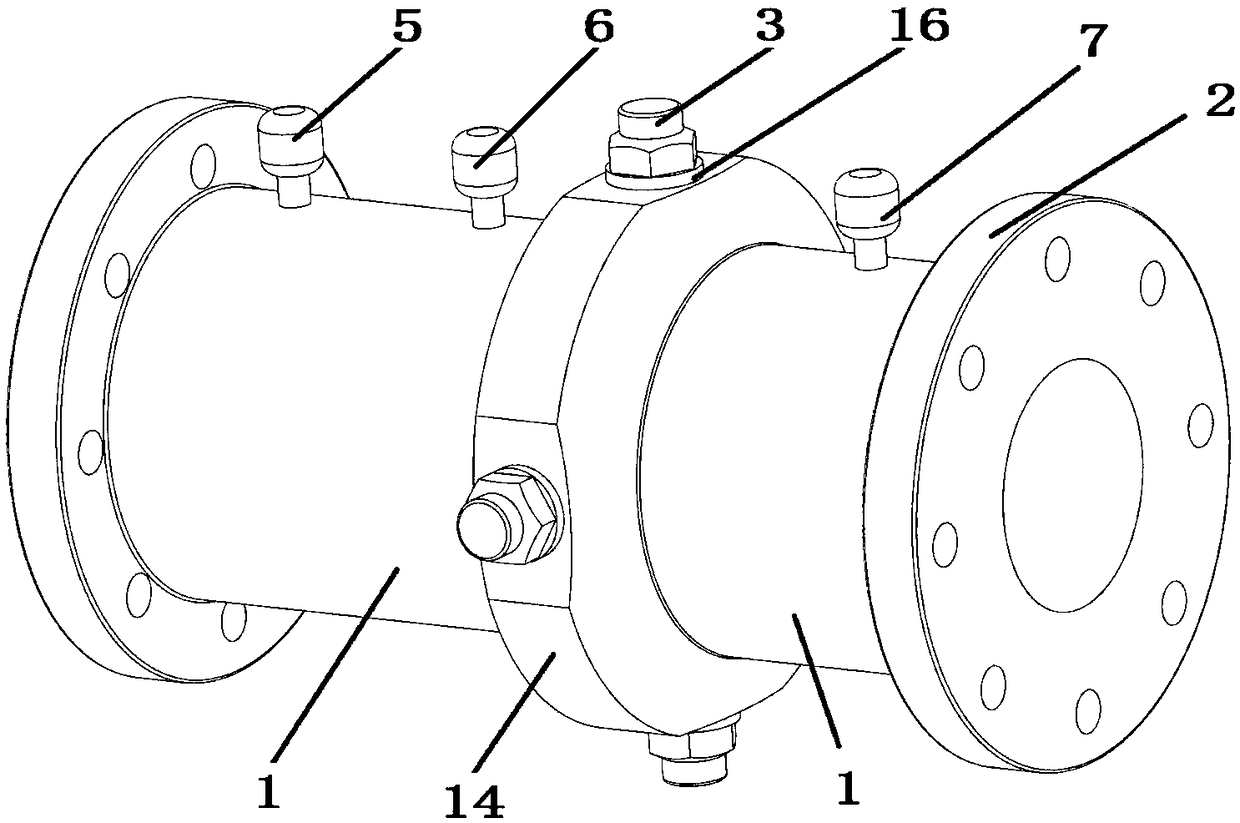

[0021] A precession type acoustic wave measurement shipboard device for rock cores, including a computer system, a data acquisition system, a pressure holding chamber, and a sonic wave transmitter 3; the pressure holding cavity is made of titanium alloy as a whole, with a circular cross section Shape, inner diameter 52mm, wall thickness 24mm, to ensure the pressure resistance of the system 20MPa, the pressure holding chamber is provided with a passage, the object to be tested extends from one end of the passage and can extend from the other end, and the pressure holding chamber is provided with A through hole with internal threads for installing the sonic wave receiver 3, one end of the sonic wave receiver 3 is provided with an external thread, and the other end is connected to the pulse transceiver in the computer system through an external signal line, and the computer system controls the sound wave generation. You can choose The P wave and S wave are sent out, which is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com