Regional online monitoring system

A regional and monitoring unit technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., to solve problems such as shortened service life, production safety accidents, and low practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

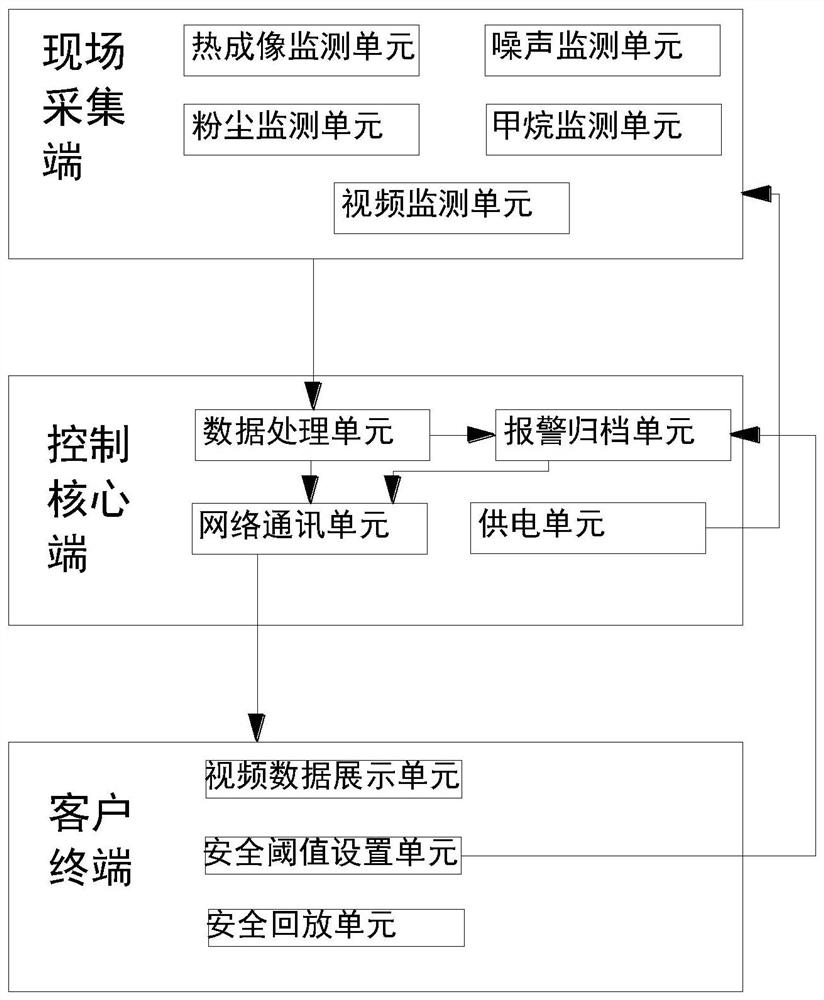

[0028] The on-site acquisition end is installed obliquely above the belt head to ensure that the measured object can enter the monitoring range of thermal imaging and cameras. The control core end is installed near the belt head for easy maintenance. The client terminal is installed in the monitoring center , the client terminal is the PC terminal, and the dust concentration information, noise information and video information at the belt head are collected through the on-site collection terminal. The collected dust information is connected to the control core terminal through the analog quantity, and the noise information is transmitted through the private The protocol is connected to the control core terminal, and the thermal imaging information and video information are connected to the control core terminal in network mode, and the control core terminal is used as the link between the field acquisition terminal and the client terminal, and is used to connect the field device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com