Rod end knuckle bearing and rod end knuckle bearing assembling equipment and assembling method

A rod end joint bearing and assembly equipment technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as the damage of the anti-corrosion coating on the surface of the rod end body, avoid corrosion failure, ensure service life, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

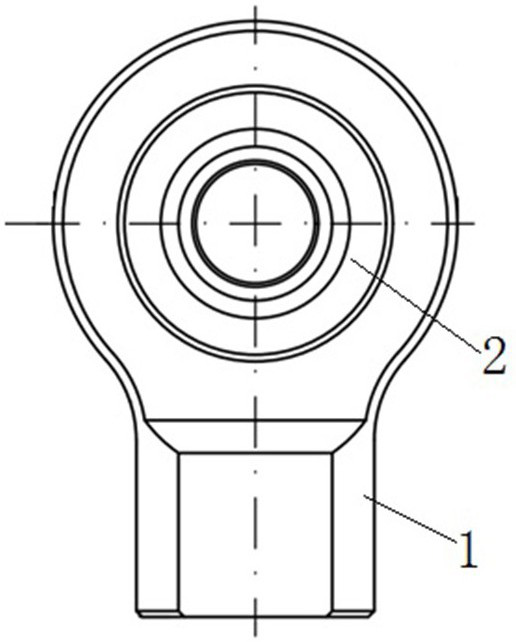

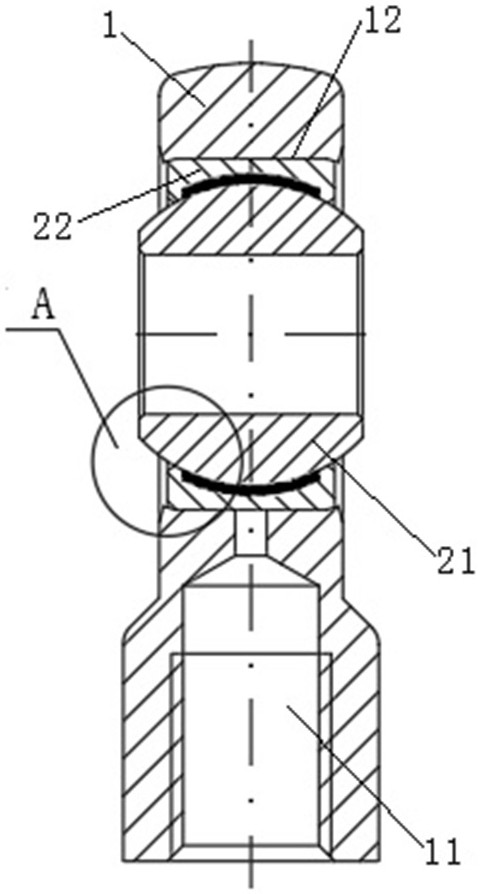

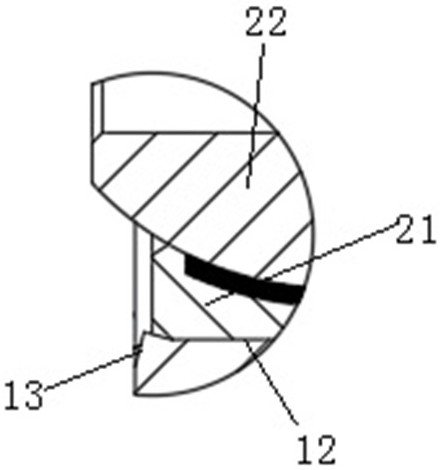

[0047] Such as Figure 1 to Figure 3 As shown, the rod end joint bearing in this embodiment includes a rod end body 1 and a bearing assembly 2. One end of the rod end body 1 is provided with an eye hole 12, and the other end is provided with a threaded hole 11. The center line of the eye hole 12 is aligned with the threaded hole 11. The center lines of the rods intersect vertically, and the rod body is made of low-alloy high-strength steel 16Mn. In order to improve the corrosion resistance of the rod end body 1, a Dacromet surface coating process is used on the outer surface of the rod end body 1 to form an anti-corrosion layer. Moreover, the threaded hole 11 at the corresponding end of the rod end body 1 adopts a fine-pitch thread to meet the fine-pitch adjustment in the narrow space of the solar tracking bracket. Of course, for the rod end body 1 , in other embodiments, the anti-corrosion layer can also be a galvanized layer.

[0048] The bearing assembly 2 includes an inne...

specific Embodiment 1

[0053] as 1 to Figure 5 As shown, the rod end joint bearing assembly equipment in this embodiment includes two extrusion dies. In this embodiment, the two extrusion dies are the first extrusion die and the second extrusion die, and the two extrusion dies are along the vertical direction Space distribution, the up and down direction here is the extrusion direction, the two extrusion dies can move towards each other along the extrusion direction, in fact, the extrusion direction is consistent with the extension direction of the center line of the rod end body 1 eye hole 12 of the rod end joint bearing , the two extrusion dies cooperate to lock the bearing assembly 2 into the eye hole 12 of the rod end body 1, and push the end faces of the two hole edges of the extrusion eye hole 12, forcing the hole to form an extruded inclined end face along the end face, The extruded inclined end face is gradually inclined towards the outer ring 22 of the bearing assembly 2 along the radial d...

specific Embodiment 2

[0067] The main difference between it and Embodiment 1 is that in Embodiment 1, only the second extrusion die is an active extrusion die, and the outer ring pushing part on the active extrusion die is elastically floating along the extrusion direction. In this embodiment, the two extrusion dies are both active extrusion dies, that is, the structures of the two extrusion dies are the same as the second extrusion die in Embodiment 1 above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com