Method for measuring oil and gas yield of single well in metering room valve group room by adopting robot

A measuring room and robot technology, which is applied in the fields of measuring, mining fluids, and earth-moving drilling and mining, etc., can solve the problems of measuring time length and liquid level height accuracy error, difficulties in instruments and automatic actuators, and limited significance, etc. Improve real-time performance, facilitate unattended operation, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

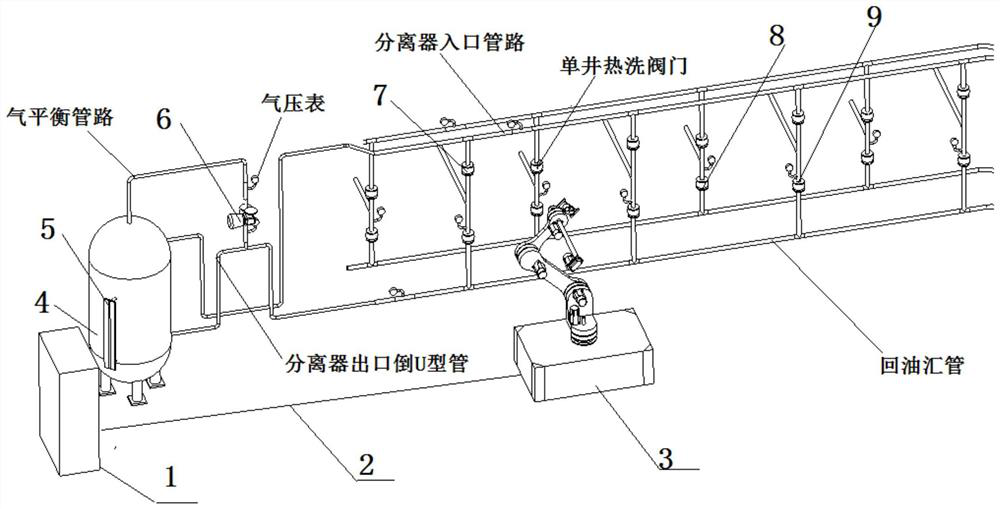

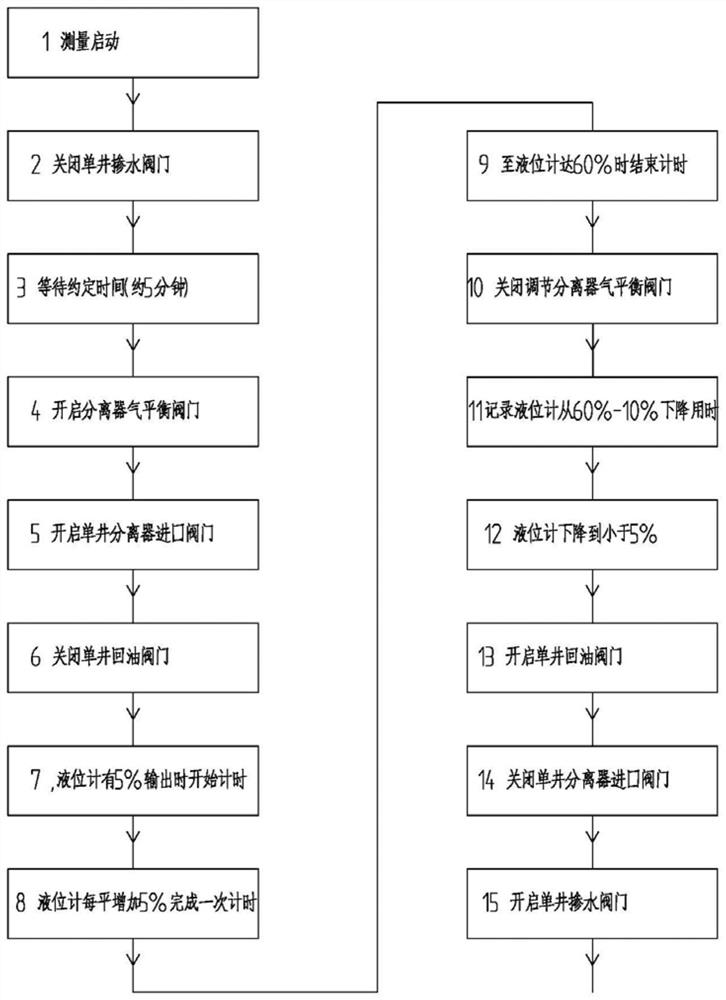

[0044] The invention provides a single-well oil and gas production measurement system in the valve group room of the metering room using a robot. In the valve group room of the metering room equipped with a U-shaped pipe device, the process of oil measurement and production measurement is automatically carried out, and the manual operation is replaced by a valve operating device. Operate each valve, cooperate with the magnetic flap liquid level gauge, process the liquid level output signal measured by the magnetic flap liquid level gauge at the same time as the measurement time, and finely measure and record the relationship between the liquid level change and the measurement time, which can be quickly and accurately The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com