Long-service-life high-strength hot-corrosion-resistant nickel-based superalloy and application thereof

A nickel-based superalloy, long-life technology, applied in the field of metal materials, can solve the problems of late development of heavy-duty gas turbines, lack of superalloy materials, etc., and achieve the effect of improving the stability of long-life tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A long-life, high-strength, heat-resistant and corrosion-resistant nickel-based superalloy, comprising the following components by weight percentage:

[0039] Cr 18.5%; Co 18.5%; Al 1.9%; Ti 3.8%; Ta 0%; W 4.9%; Mo 1.0%; Nb 1.2%; C 0.1%; B 0.002%; Zr 0.017%;

[0040] The above-mentioned alloy is used to prepare a test bar, and the ingredients are mixed according to the ingredients in the alloy, and then melted in a vacuum induction furnace. At a temperature of 1550 ° C ~ 1580 ° C, refining for 5 min ~ 10 min, and then at a temperature of 1410 ± 20 ° C Casting under conditions, the temperature range of the shell temperature is 850±50°C, after pouring, a cast nickel-based superalloy test rod is obtained. Among them, the heat treatment parameters of the superalloy test rod are: 1160±10°C / 4h, 850±20°C / 16h. The N of the superalloy test bar v The value is 2.39.

Embodiment 2

[0042] Different from Example 1, the long-life, high-strength, hot-corrosion-resistant nickel-based superalloy of Example 2 includes the following components by weight percentage:

[0043] Cr 18.5%; Co 18.9%; Al 1.9%; Ti 3.8%; Ta 0.1%; W 4.9%; Mo 1.0%; Nb 1.2%; C 0.1%; B 0.015%; Zr 0.017%;

[0044] Its preparation method is the same as that of Example 1 and will not be repeated here.

[0045] The N of the obtained superalloy test bar v The value is 2.38.

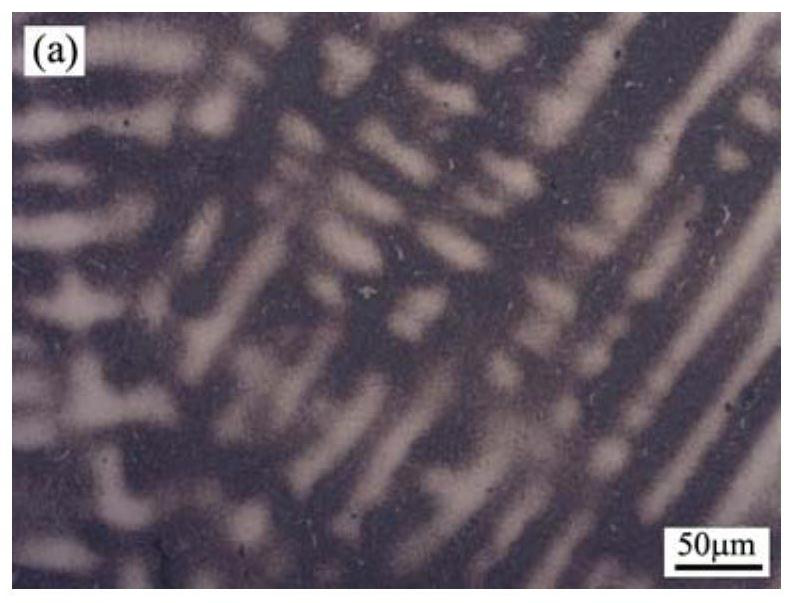

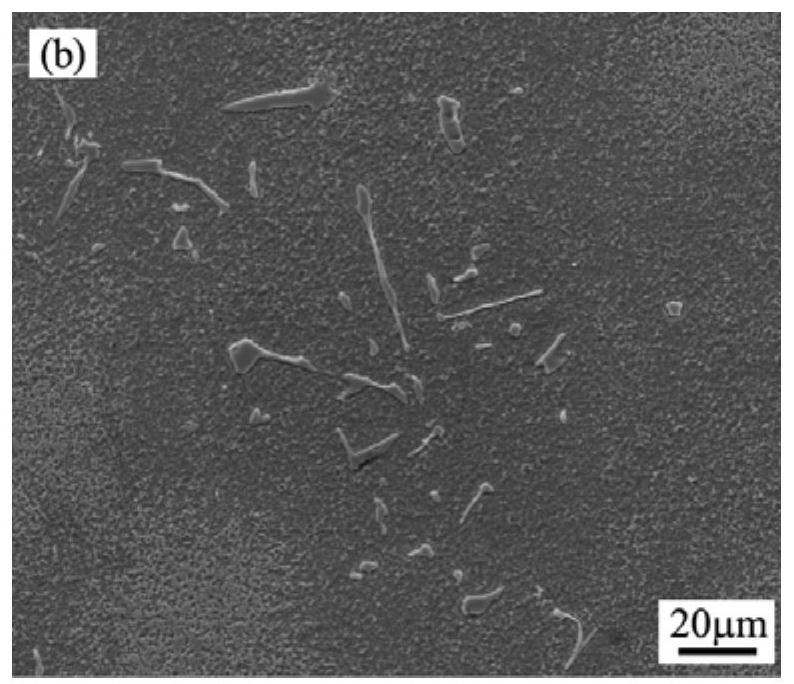

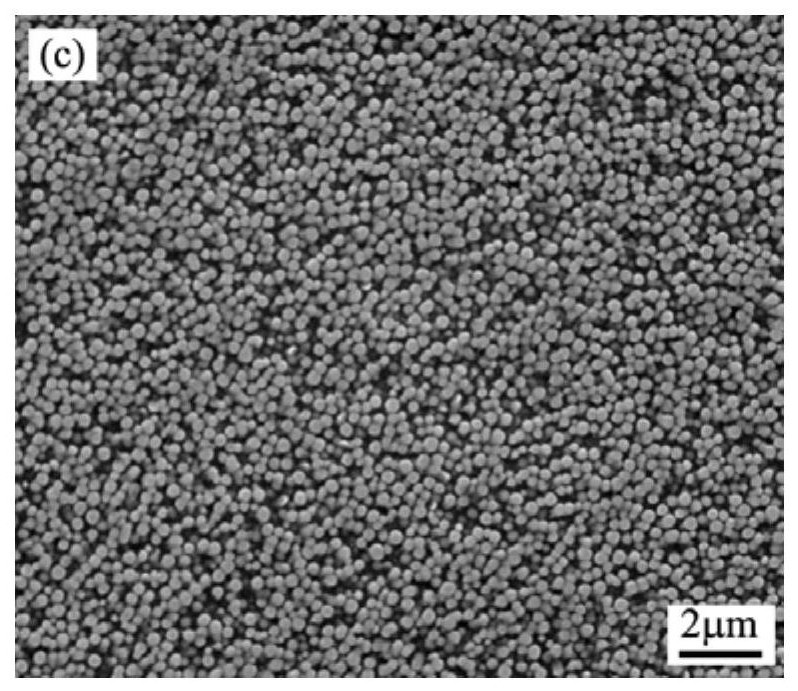

[0046] The microstructure of the superalloy test bar is as follows: Figure 1 to Figure 3 As shown, among them, figure 1 is the as-cast structure diagram, figure 2 20μm microstructure of heat treatment state, image 3 The heat-treated microstructure of 2μm. From figure 1 It can be seen that there is no γ / γ′ phase eutectic structure in the as-cast alloy, from figure 2 It can be seen that after heat treatment, there is no η phase precipitation, from image 3 It can be seen that the γ′ phase structure is spherical, wit...

Embodiment 3

[0048] Different from Example 1, the long-life, high-strength, hot-corrosion-resistant nickel-based superalloy of Example 3 includes the following components by weight percentage:

[0049] Cr 19.0%; Co 19.0%; Al 2.0%; Ti 3.9%; Ta 0.1%; W 4.5%; Mo 1.0%; Nb 1.3%; C 0.1%; B 0.015%; Zr 0.017%;

[0050] Its preparation method is the same as that of Example 1 and will not be repeated here.

[0051] The N of the obtained superalloy test bar v The value is 2.46.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com