Outdoor floor water-based asphalt bottom paint and processing technology thereof

A technology for modifying asphalt and asphalt, applied in the field of water-based asphalt primer for outdoor floors and its processing technology, can solve problems such as poor overall application effect and poor corrosion resistance, achieve good thermal stability and flame retardant effect, and improve mechanical strength. , The effect of improving aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

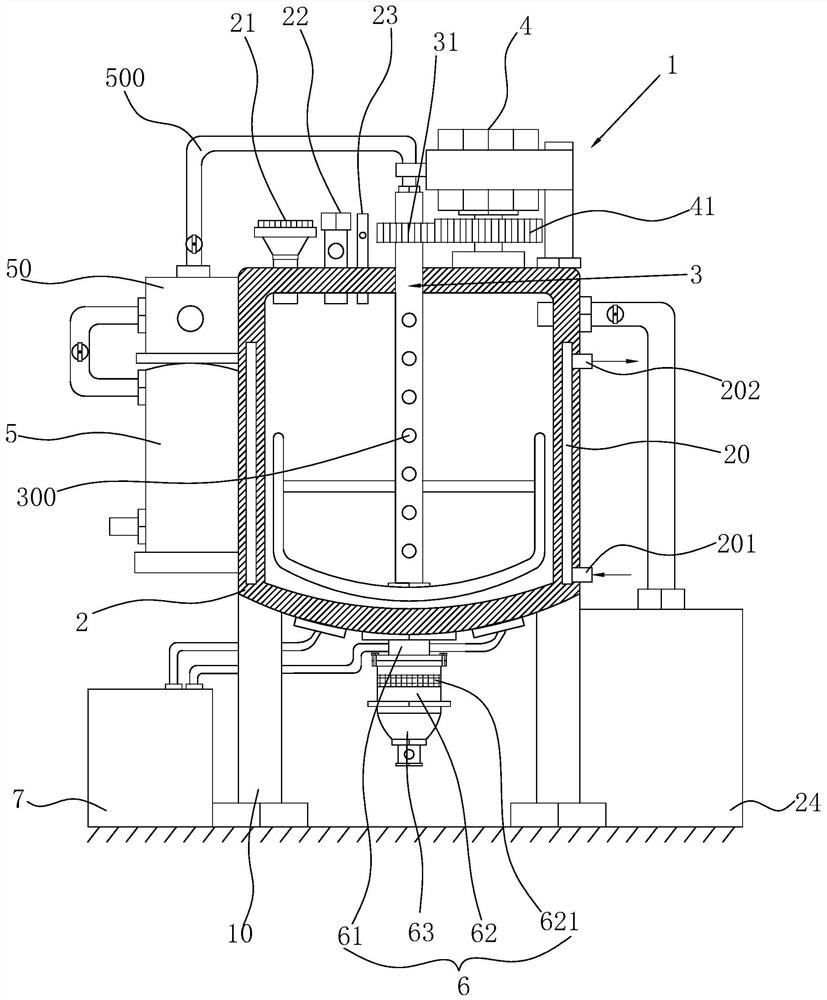

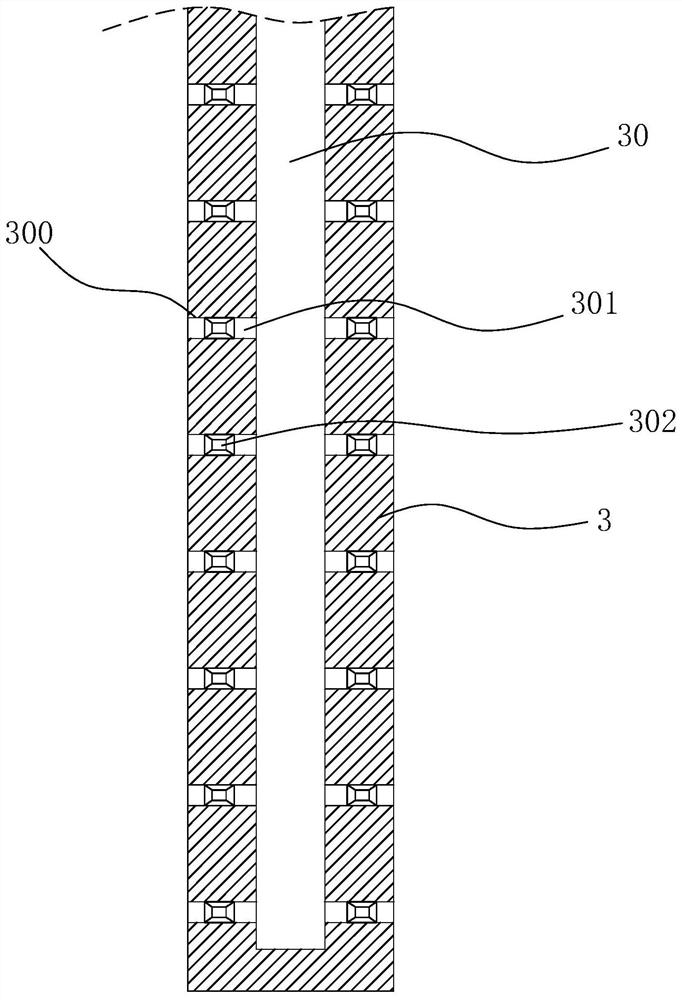

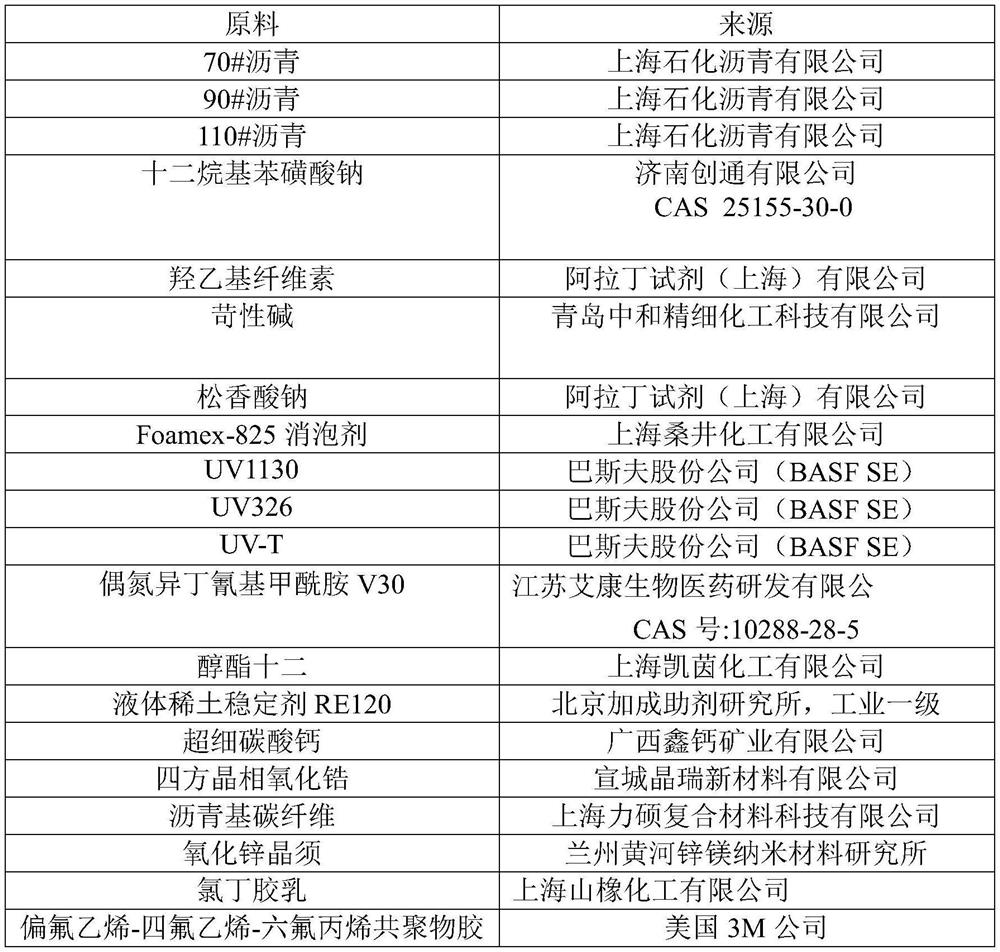

[0053] The preparation method of modified asphalt A may further comprise the steps:

[0054] Step 1, weigh 1.3 parts of sodium dodecylbenzenesulfonate, 0.8 parts of Foamex-825 defoamer, 1.2 parts of hydroxyethyl cellulose, 0.6 parts of caustic alkali, 1.5 parts of sodium abietate And 42 parts of deionized water, put into the first reactor (commercially available, the electric heating reactor of Laizhou Shenglong Chemical Machinery Co., Ltd.), be warming up to 40 ℃, under the stirring speed of 400 rev / mins, mix 10 Minutes, then heated up to 60 ℃ to save the spare material A;

[0055] Step 2, weighing 50 parts of 70# asphalt, 12.5 parts of 90# asphalt and 5 parts of 110# asphalt, first throw 70# asphalt into the second reactor (commercially available, Laizhou Shenglong Chemical Machinery Co., Ltd. Electric heating reaction kettle), heated to 80°C, and kept stirring for 15 minutes at a stirring speed of 200 rpm, then poured 90# asphalt into the second reaction kettle, controlled...

preparation example 2

[0058] The difference between Preparation Example 2 and Preparation Example 1 is that modified asphalt B is prepared from the following raw materials in parts by weight: 47.6 parts of 70# asphalt, 8.2 parts of 90# asphalt, 2.2 parts of 110# asphalt, 1.2 parts of Sodium dodecylbenzenesulfonate, 0.8 parts of Foamex-825 defoamer, 1.0 parts of hydroxyethyl cellulose, 0.4 parts of caustic, 1.4 parts of sodium abietate and 40 parts of deionized water.

preparation example 3

[0060] Compounding of fillers: Weigh ultrafine calcium carbonate, tetragonal zirconia, pitch-based carbon fiber, and zinc oxide whiskers at a mass ratio of 8.8:1.2:2.3:0.8 , zinc oxide whiskers, put ultra-fine calcium carbonate, tetragonal zirconia, pitch-based carbon fiber, and zinc oxide whiskers into the disperser (twin-shaft stirring disperser, electric heating reactor of Laizhou Shenglong Chemical Machinery Co., Ltd.) , at a stirring speed of 200 rpm, stirred for 2 minutes to obtain filler A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com