Bromination process of star-branched butyl rubber

A bromination and process technology, applied in the field of rubber, can solve the problems affecting the processing performance of brominated butyl rubber and the low content of Type II secondary structure rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

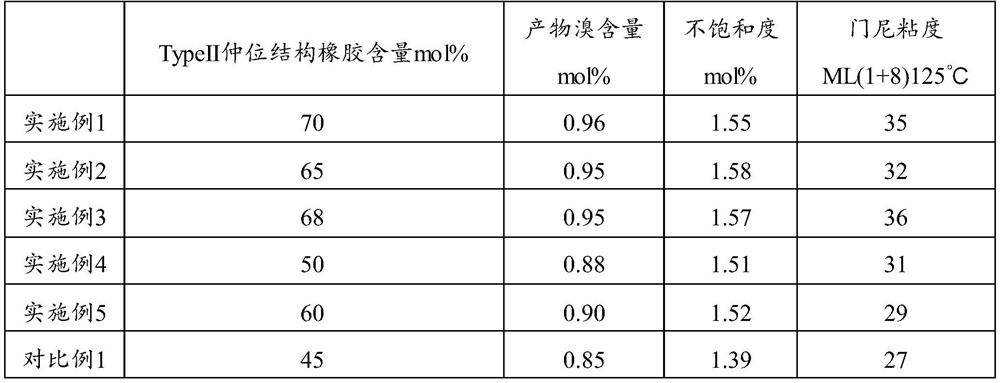

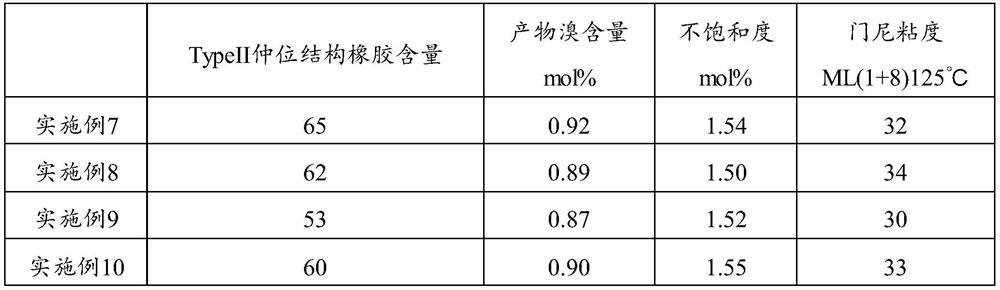

Examples

Embodiment 1

[0064] With n-hexane as aliphatic hydrocarbon and cyclohexane as branching agent capture agent; Br 2 is a brominating agent, and NaOH solution (mass fraction 2wt%) is a neutralizing agent. The specific process is as follows:

[0065] S1. Weigh 30g of star-branched butyl rubber, add 170g of n-hexane, swell, stir and dissolve, and obtain a glue solution with a mass fraction of 15wt%.

[0066] S2. Add 9 g of cyclohexane to the obtained glue solution, and stir for 30 minutes to obtain a mixed solution.

[0067] S3. Add Br to the obtained mixed solution under the condition of avoiding light at 40°C 2 n-hexane solution (Br 2 0.42mL, n-hexane 15mL; Br 2 The molar ratio to the unsaturated double bond in the star-branched butyl rubber is 0.92:1), stirred and reacted for 10 minutes to obtain the brominated glue.

[0068] S4. Add 25g NaOH solution (mass fraction 2wt%, the molar ratio of NaOH to the bromine element in the brominating agent is 0.76:1) to the obtained brominated glue, ...

Embodiment 2

[0072] With n-hexane as aliphatic hydrocarbon and cyclohexane as branching agent capture agent; Br 2 is a brominating agent, NaClO is an oxidizing agent, and NaOH solution (mass fraction 2wt%) is a neutralizing agent. The specific process is as follows:

[0073] S1. Weigh 30 g of star-branched butyl rubber, add 157.5 g of n-hexane, swell, stir and dissolve, and obtain a glue solution with a mass fraction of 16 wt%.

[0074] S2. Add 3 g of cyclohexane to the obtained glue solution, and stir for 30 minutes to obtain a mixed solution.

[0075] S3, under the condition of 40°C in the dark, add 10g NaClO solution (mass fraction is 10wt%), Br 2 n-hexane solution (Br 2 0.34mL, n-hexane 10mL; Br 2 The molar ratio to the unsaturated double bond in the star-branched butyl rubber is 0.74:1), stirred and reacted for 10 minutes to obtain the brominated glue.

[0076] S4, add 20g NaOH solution (mass fraction 2wt%, the molar ratio of NaOH to the bromine element in the brominating agent i...

Embodiment 3

[0080] With n-hexane as aliphatic hydrocarbon, benzene as branching agent and capture agent; HBr as bromination agent, NaBrO 3 is an oxidizing agent, and NaOH solution (mass fraction 2wt%) is a neutralizing agent. The specific process is as follows:

[0081] S1. Weigh 30g of star-branched butyl rubber, add 120g of n-hexane, swell, stir and dissolve, and obtain a glue solution with a mass fraction of 20wt%.

[0082] S2. Add 15 g of benzene to the obtained glue solution, and stir for 30 minutes to obtain a mixed solution.

[0083] S3. Add 10 g of NaBrO to the resulting mixed solution under the condition of 40°C in the dark. 3 Aqueous solution (mass fraction is 20wt%), 4g HBr aqueous solution (massfraction is 40wt%; The molar ratio of bromine element and unsaturated double bond in the star-branched butyl rubber is 3.64: 1), stirring reaction 10min, obtains bromination After glue.

[0084] S4, add 50g NaOH solution (mass fraction 2wt%, the molar ratio of NaOH and the bromine e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com