Microbial soil improver containing furnace ash and application thereof

A technology of soil microorganisms and improvers, which can be used in applications, soil conditioning materials, fertilizers made from biological wastes, etc., can solve problems such as degradation of cultivated land soil quality, damage to soil ecological environment, and impact on sustainable development of agricultural economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

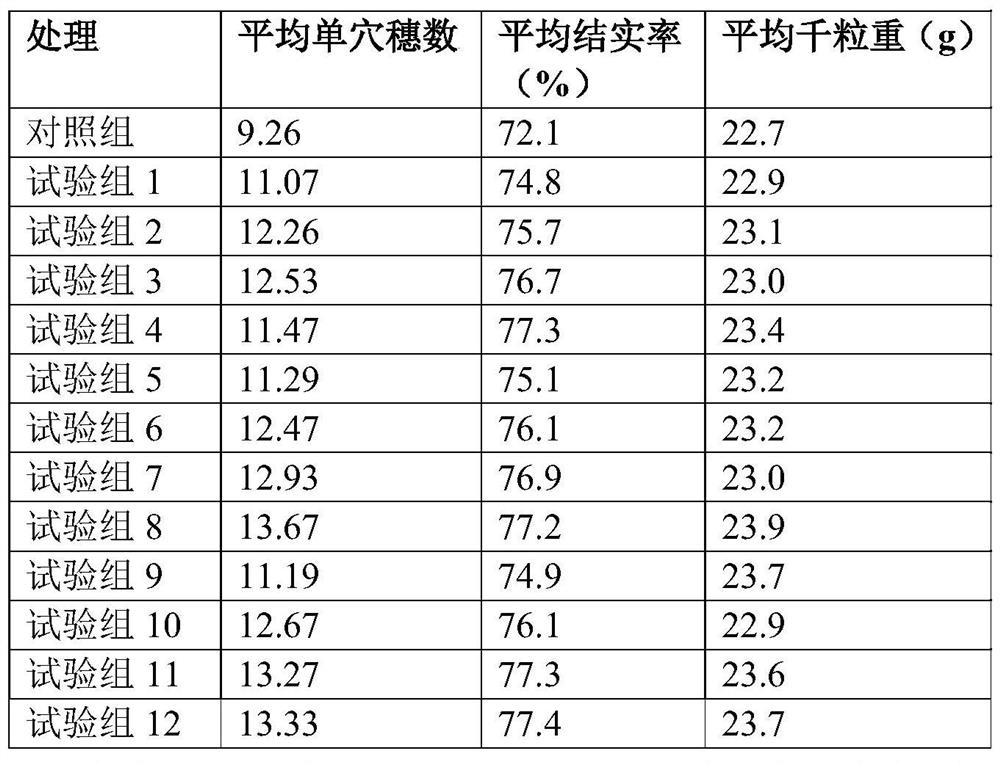

Examples

preparation Embodiment 1

[0022] Preparation Example 1: Preparation of Microbial Improver

[0023] First, prepare 1000g of composite bacterial agent by using the following various bacterial powders: 50g of Aspergillus palsaceae powder, 50g of yellow-blue fungus powder, 100g of polythecene pink powder, 150g of Trichoderma harzianum powder, and 100g of Verticillium chlamydoides Bacteria powder, 200g Lactobacillus plantarum powder, 100g Saccharomyces cerevisiae powder and 250g Bacillus subtilis powder. The total effective number of viable bacteria in the prepared composite microbial agent was 4.7ⅹ10 11 CFU / g.

[0024] Next, the soil microbial amendment of this example was prepared. The raw materials used include: 5g of compound bacterial agent, 100g of beet molasses, 50g of urea, 100g of secondary powder and 4750g of furnace ash. First, mix the above-mentioned prepared composite bacterial agent into beet molasses and mix uniformly to obtain a molasses bacterial agent mixture, then mix the molasses bac...

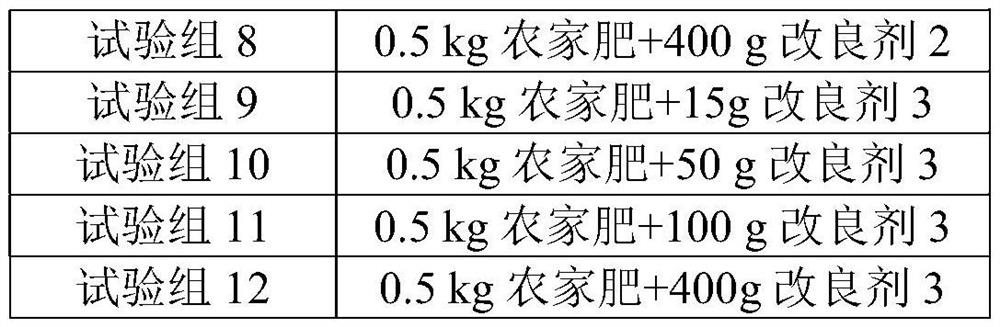

preparation Embodiment 2

[0025] Preparation Example 2: Preparation of Microbial Improver

[0026] Prepare composite bacterial agent and the soil microorganism improvement agent of the present embodiment by the method identical with embodiment 1, wherein the raw material ratio of composite bacterial agent is identical with embodiment 1, but the raw material ratio of microbial improvement agent is different from embodiment 1.

[0027] The raw materials of the microbial improvement agent in this embodiment include: 100 g of composite bacterial agent, 250 g of sucrose molasses, 100 g of urea, 250 g of secondary powder and 4000 g of furnace ash.

[0028] Finally, a total amount of about 5 kg of modifier was obtained, which was called modifier 2.

preparation Embodiment 3

[0029] Preparation Example 3: Preparation of Microbial Improver

[0030] Prepare composite bacterial agent and the soil microorganism improvement agent of the present embodiment by the method identical with embodiment 1, wherein the raw material ratio of composite bacterial agent is identical with embodiment 1, but the raw material ratio of soil microorganism improvement agent is different from embodiment 1 .

[0031] The raw materials of the microbial improvement agent in this embodiment include: 250g of composite bacterial agent, 250g of sucrose molasses, 250g of urea, 250g of secondary powder and 4000g of furnace ash.

[0032] Finally, a total amount of about 5 kg of improver was obtained, which was called improver 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com