Cigarette carton removing device

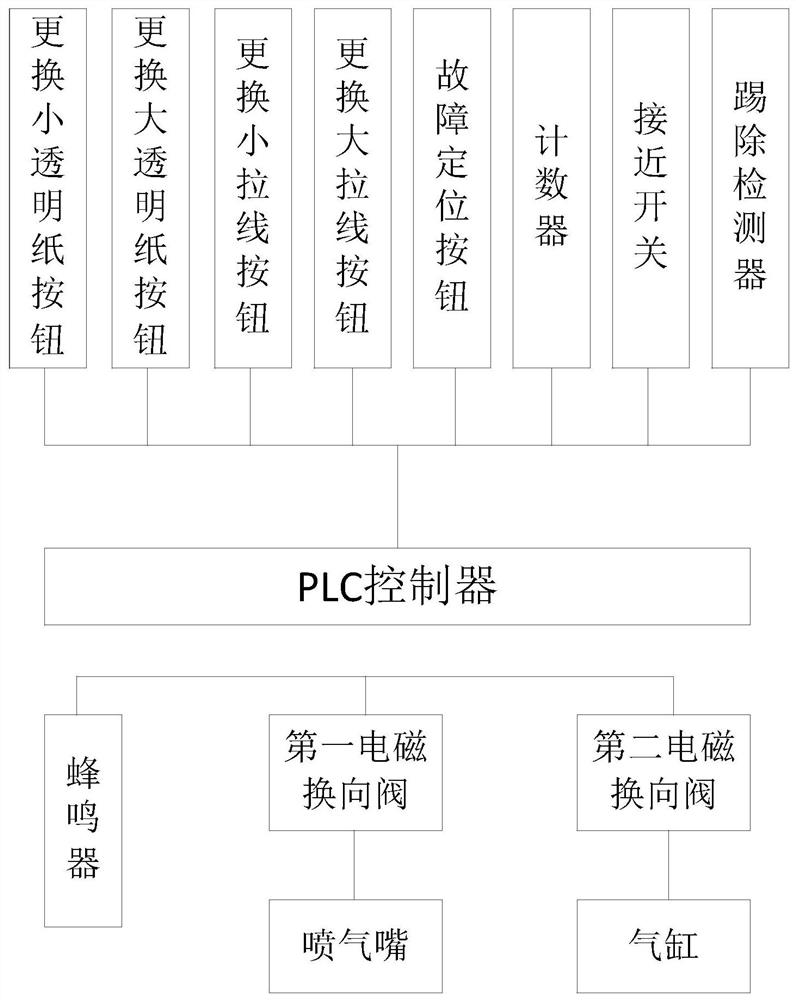

A technology for removing devices and tobacco rods, which is applied in the field of cigarette production, can solve the problems of no automatic centering and correcting position mechanism, hidden dangers in quality, and inability to identify by appearance imaging cameras, so as to achieve the effect of reducing quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

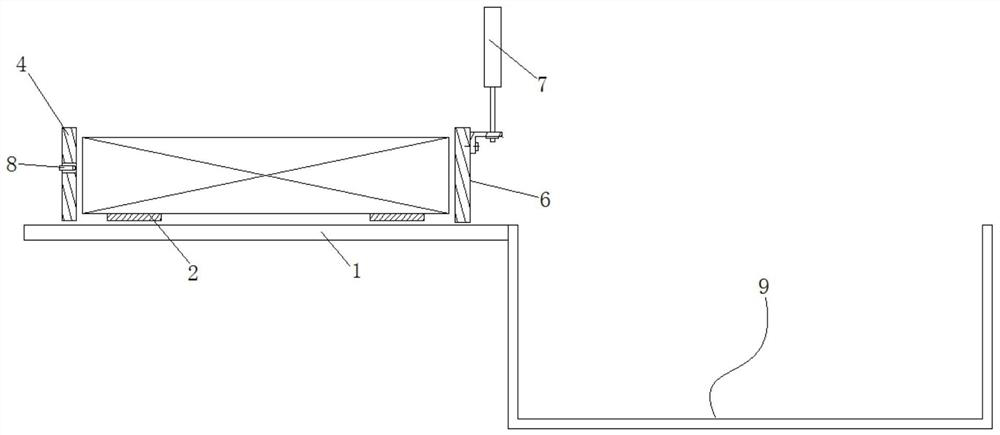

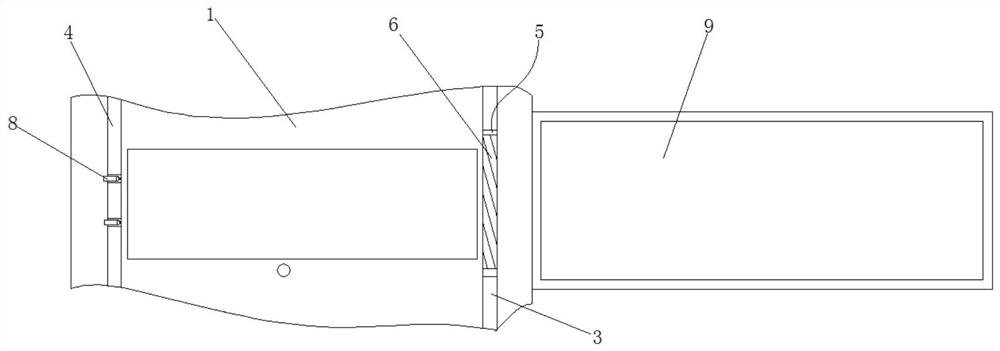

[0034] Please refer to Figure 1 to Figure 3 , the present invention proposes a tobacco rod rejecting device, which includes a base body 1, the base body 1 is a strip plate, and its length direction is consistent with the conveying direction of the tobacco rods.

[0035] Specifically, a conveyor belt 2 is provided above the base body 1 to form a delivery channel for tobacco rods; during implementation, a gap is left between the base body 1 and the conveyor belt 2 .

[0036] Both sides of the base body 1 are respectively provided with a first side plate 3 and a second side plate 4, the base body 1 is provided with a rejecting area, and a described first side plate 3 facing the rejecting area is provided with a There is a rejecting port 5, a baffle plate 6 is arranged at the rejecting port 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com