Automatic trimming system for tyre

A technology for trimming and tires, which is applied in the field of tire automatic trimming system, can solve the problems of high labor intensity, defects, tire shaving quality and other problems, and achieve the effect of reducing labor intensity, reducing quality defects, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

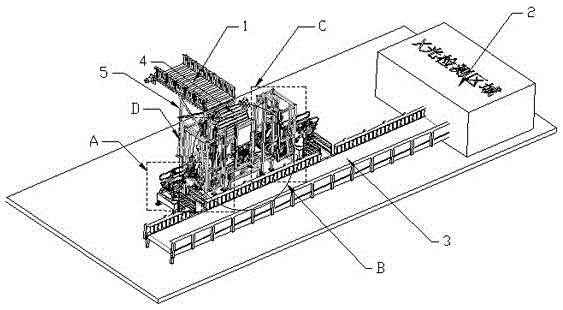

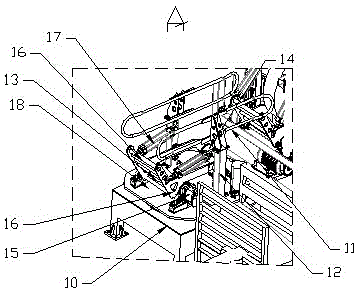

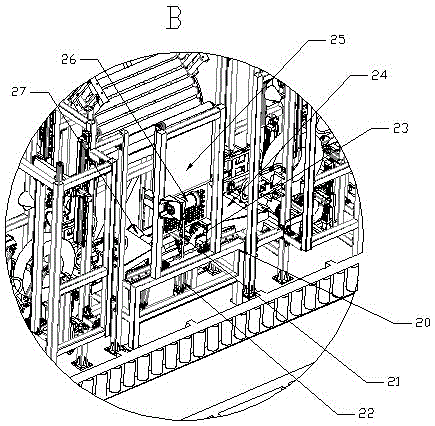

[0028] Such as Figure 1-Figure 7 From the schematic diagram shown, it can be seen that the automatic tire trimming system of the present invention includes a tire retreading code scanning mechanism, a trimming mechanism, a trimming detection mechanism, and a finished product delivery mechanism.

[0029] There are two edge trimming mechanisms and edge trimming detection mechanisms, which are symmetrically arranged on both sides of the tire retreading code scanning mechanism, and the tire retreading code scanning mechanism, edge trimming mechanism and edge trimming detection mechanism are arranged in sequence along the conveying direction of the tire.

[0030] The finished product conveying mechanism includes a finished product conveyor belt 3 and an X-ray detection area 2. The finished product conveyor belt 3 has two feeding ports corresponding to the trimming detection mechanism. The X-ray detection area 2 is located at the discharge port of the finished product conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com