Flake silver powder as well as preparation method and application thereof

A flake silver powder and silver powder technology, which is applied in transportation and packaging, metal processing equipment, cable/conductor manufacturing, etc., can solve the problems of increasing types of residual substances on the surface, increasing the difficulty of cleaning, and affecting the use of products. It is suitable for large-scale Industrial production, good sheet structure, easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

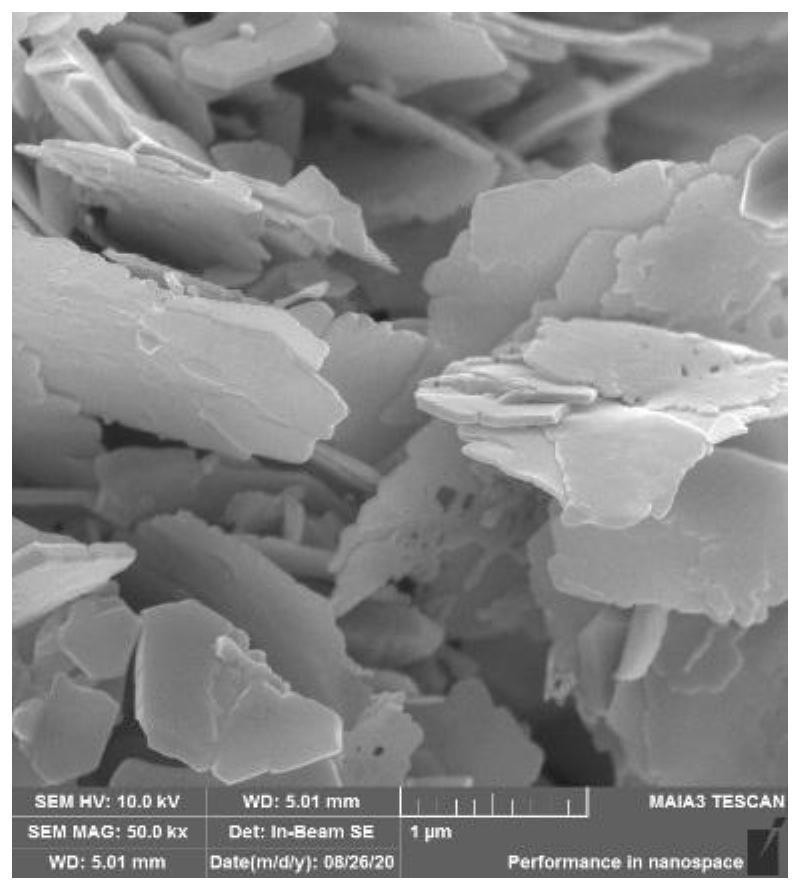

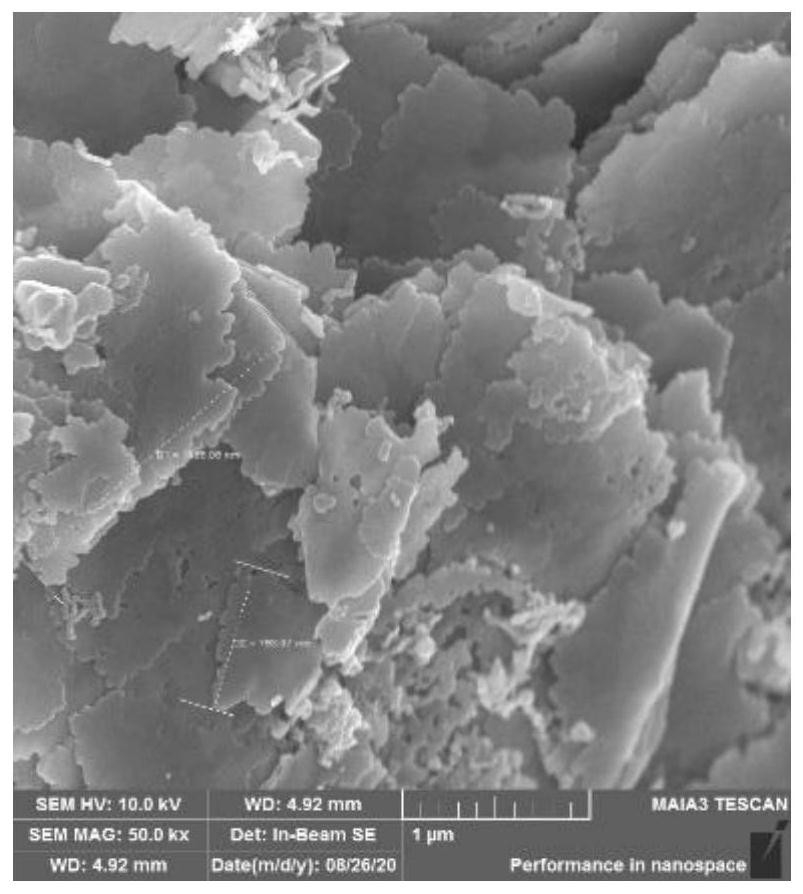

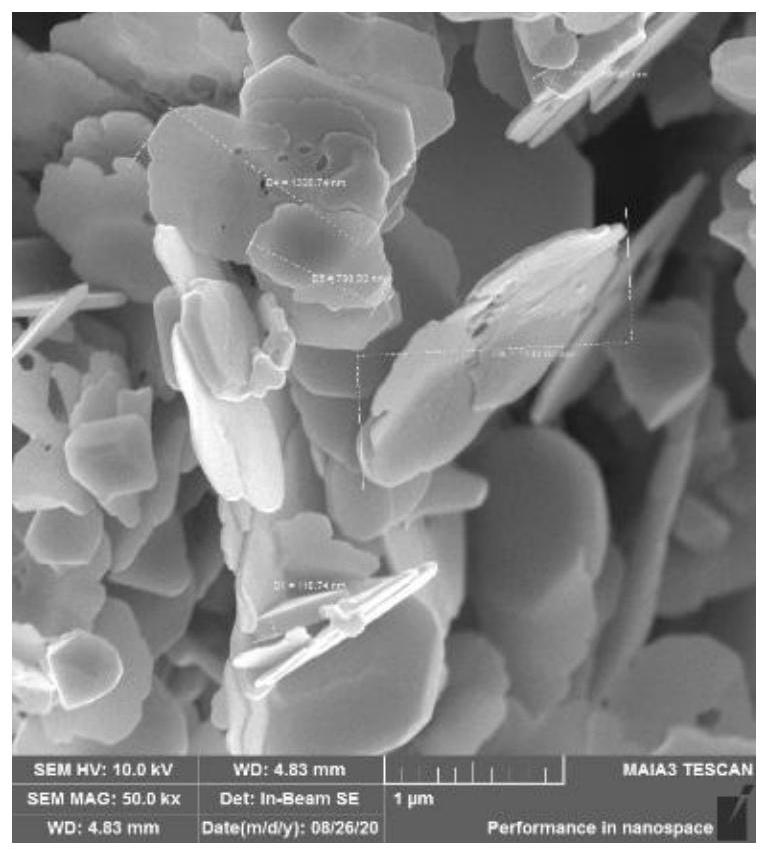

Image

Examples

Embodiment 1

[0044]Take 10g of silver nitrate and add it to 250g of deionized water, stir and dissolve it fully, add 1g of polyvinylpyrrolidone to the silver nitrate solution; dissolve another 6.5g of ascorbic acid in 250g of deionized water to make a reducing agent solution; add ammonia solution to the silver nitrate solution Regulate pH to 10, stir to make solution clarification, promptly the concentration of silver ion in the solution containing silver ion is 0.24mol / L, dispersant is 10wt% of silver source; Get 20% ascorbic acid solution and join in 20% silver nitrate solution, fully After 20 minutes, use a peristaltic pump to add the remaining silver nitrate solution and ascorbic acid solution into the reaction solution, continue to stir and reduce, the stirring rate is 1000r / min, and the reaction temperature is controlled at 20°C.

[0045] After the reaction was completed, the reaction solution was separated from solid and liquid, washed three times with deionized water, then washed on...

Embodiment 2

[0048] Dissolve 10g of silver nitrate in 250g of deionized water, add 1.5g of polyvinylpyrrolidone to the silver nitrate solution; dissolve another 6.5g of ascorbic acid in 250g of deionized water to make a reducing agent solution; add ammonia solution to the silver nitrate solution to adjust the pH To 10, stir to make the solution clear, that is, the concentration of silver ions in the solution containing silver ions is 0.24mol / L, and the dispersant is 15wt% of the silver source; 20% ascorbic acid solution is added to 20% silver nitrate solution, fully stirred and reduced After 20 minutes, use a peristaltic pump to add the remaining silver nitrate solution and ascorbic acid solution into the reaction solution, continue to stir for reduction, the stirring rate is 1000r / min, and the reaction temperature is controlled at 25°C.

[0049] After the reaction was completed, the reaction solution was separated from solid and liquid, washed three times with deionized water, then washed ...

Embodiment 3

[0052] Dissolve 10g of silver nitrate in 250g of deionized water, fully dissolve 1.5g of ethyl cellulose in 20ml of ethanol, add the ethyl cellulose solution into the silver nitrate solution, and mix well; another 6.5g of ascorbic acid is dissolved in 250g of Make a reducing agent solution in deionized water; add ammonia solution to the silver nitrate solution to adjust the pH to 9, stir to make the solution clear, that is, the concentration of silver ions in the silver ion solution is 0.24mol / L, and the dispersant is 15wt% of the silver source Get 40% ascorbic acid solution and join in 40% silver nitrate solution, fully stir reduction, use peristaltic pump to join remaining silver nitrate solution and ascorbic acid solution in the reaction solution after 20min, continue stirring reduction, stirring speed 900r / min, reaction The temperature was controlled at 35°C.

[0053] After the reaction was completed, the reaction liquid was separated from solid and liquid, washed once wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com