Method for detecting content of components in slurry or glue solution in regenerated viscose

A detection method, viscose fiber technology, applied in the direction of weighing, analyzing materials, and measuring devices by removing certain components, can solve problems such as difficult to obtain spectra, poor fluidity, and quantitative model prediction performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

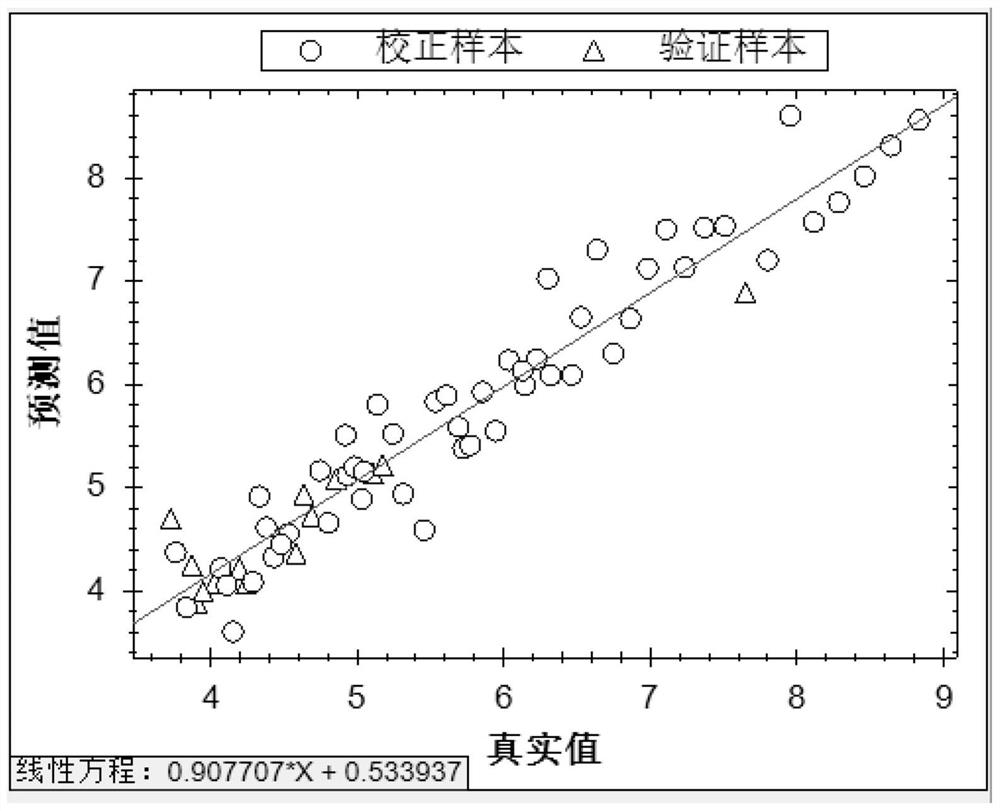

[0034] This example illustrates the preparation of calibration porridge samples with different component contents and the determination process of quality indicators water content, 4-methylmorpholine-N-oxide (NMMO), and water content calibration values.

[0035] 1) Preparation of calibration pulp porridge samples

[0036] The minimum value of cellulose content in the prepared 75 calibration pulp samples was 3.728%, and the maximum value was 9.031%. The minimum NMMO content is 45.157%, and the maximum is 48.001%. The minimum value of water content is 45.811%, and the maximum value is 48.271%.

[0037] 2) Determination of the calibration value of the component content of the calibration pulp porridge sample

[0038] The cellulose content, NMMO content and water content were selected as the key quality control indicators of the porridge and glue samples, and the calibration values of the three components were determined by spectrophotometer and difference method after cooking...

example 2

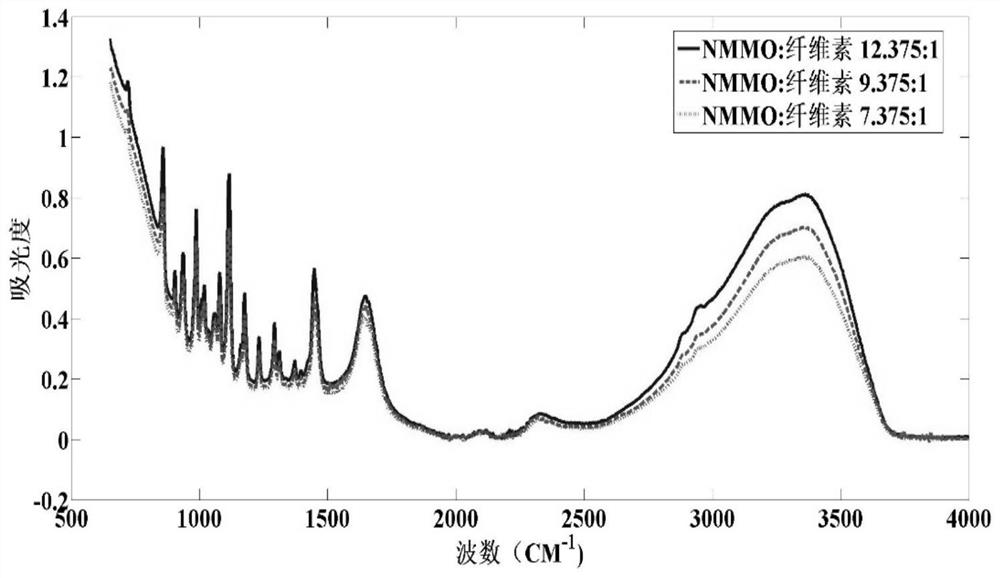

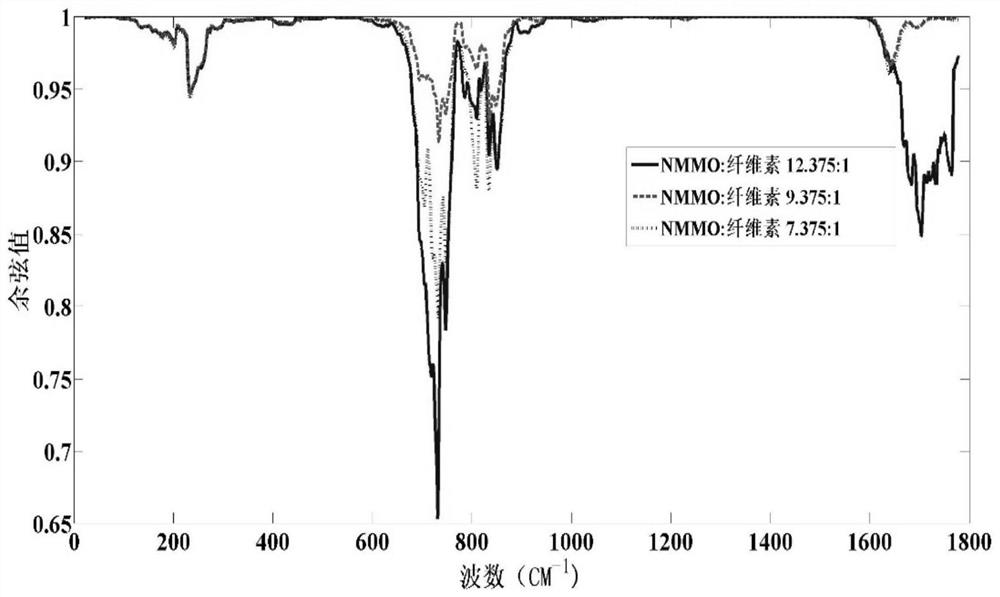

[0048] This example shows that the pretreatment method of the conversion angle spectrum can significantly eliminate the phenomenon that the accuracy of the measurement spectrum is reduced caused by the sample being too viscous and entrained air bubbles, and combined with the partial least squares method to determine the internal index components (cellulose, NMMO) of the calibration glue sample and moisture) content.

[0049] 1) Preparation of Calibration Glue Samples

[0050] The above-mentioned pulp and porridge samples were stirred under vacuum at 90°C for 120 minutes to prepare glue samples. A total of 75 glue samples were prepared. Among them, the cellulose content is 6.309%-14.778%. The NMMO content value is 73.888%-81.230%. The water content is 12.461%-11.335%.

[0051] 2) Adopt the same spectrometer and spectral measurement conditions as the pulp porridge sample in Example 2, and the same measurement method and measurement conditions for the calibration value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com