A quantitative fluorescence analysis method for cobalt-based alloys

A cobalt-based alloy, fluorescence analysis technology, applied in the field of analysis, can solve the problems of short analysis period, long analysis period, complicated operation, etc., and achieve the effect of solving the problem of component detection, shortening the analysis period and improving the detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for quantitative fluorescence analysis of cobalt-based alloys, comprising the steps of:

[0029] (1), set the X-ray fluorescence spectrometer, adjust the instrument to adapt to the analysis of cobalt-based alloys, and set the parameters as follows:

[0030] Test equipment: Shimadzu XRF-1800 sequential spectrometer, 40Kw rhodium target.

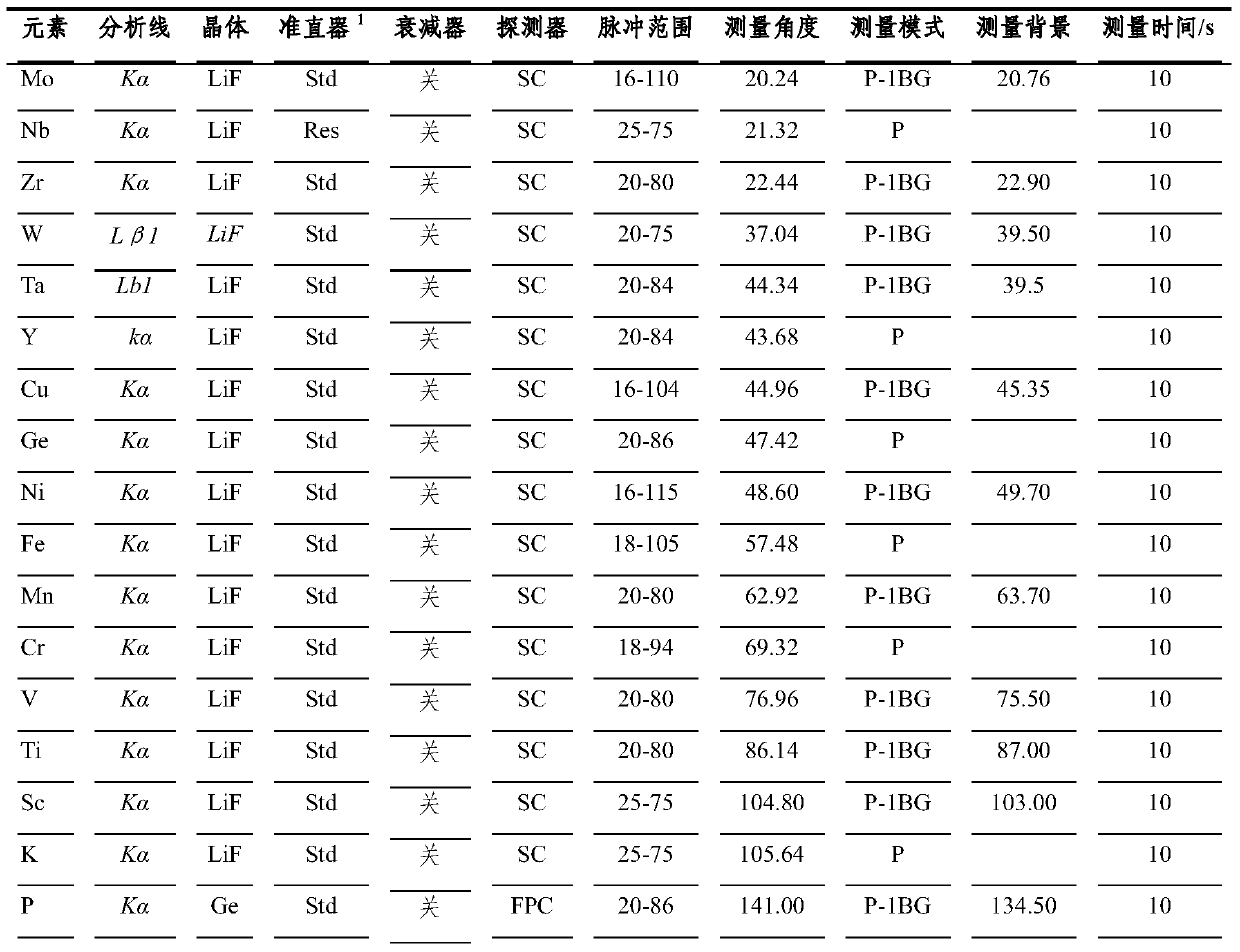

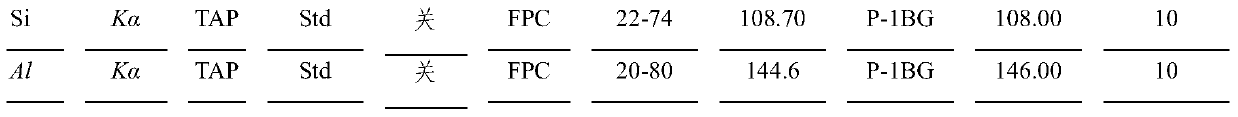

[0031] Condition setting: the diameter of the mask is 20mm, Cr and elements with larger atomic numbers, the voltage and current are selected as 60kVx55mA, the elements of P and below are selected as 30kVx110Ma, and other measurement parameters are shown in Table 1.

[0032] Table I

[0033]

[0034]

[0035] (2) Measure the standard substance, find out the correlation coefficient of the matrix correction between elements and the overlapping interference of spectral lines, and determine the linear relationship between the content of each element and the intensity of characteristic spectral lines. in:

[0036] The overla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com