An expandable pressure-resistant pipe

A technology for pressure-resistant pipes and inner-layer pipes, applied in the field of expanded pressure-resistant pipes, can solve the problems of relieving internal pressure, pipe rupture, and brittleness of hard pipes, achieving high reliability and service life, preventing corrosion, avoiding cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

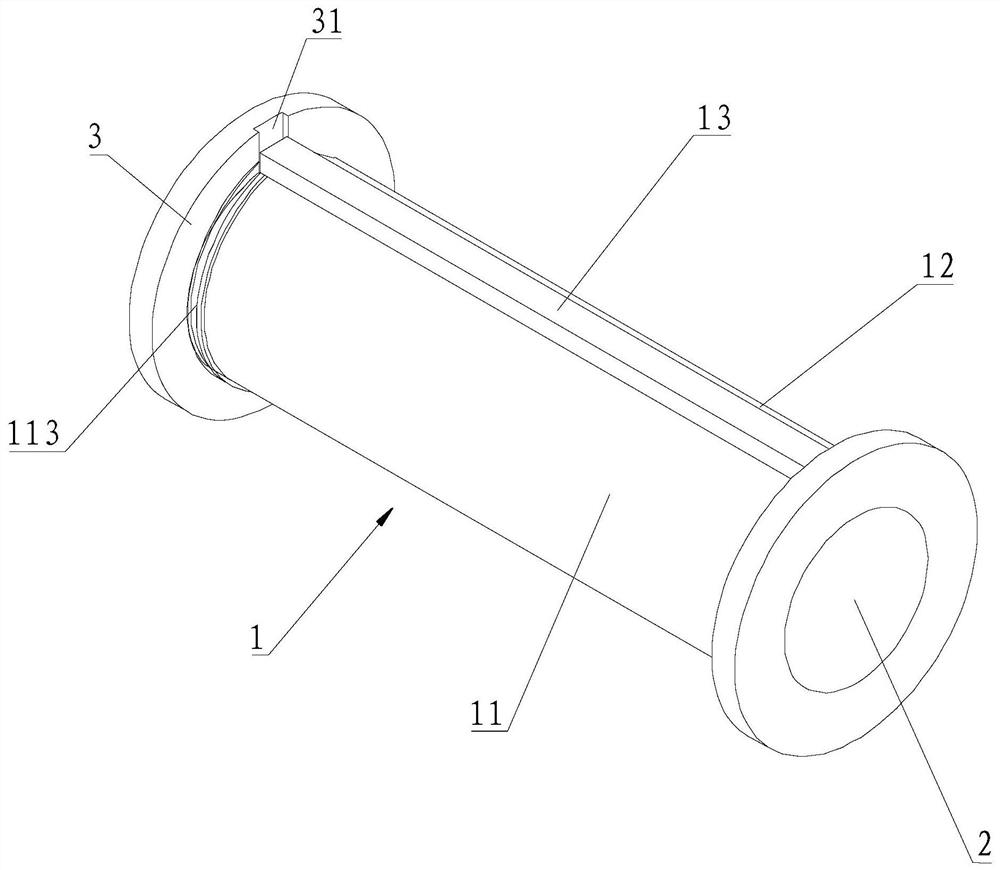

[0052] An expansion pressure-resistant pipe, comprising a hard outer pipe sleeve 1 and a flexible inner pipe 2;

[0053] Both ends of the inner layer tube 2 are respectively provided with a retaining ring 3, and the outer surface of the inner layer tube 2 is divided into a left half-arc surface and a right half-arc surface that are symmetrical to each other along any plane passing through the axis of the tube. , the right half arc surface is provided with a raised portion 21;

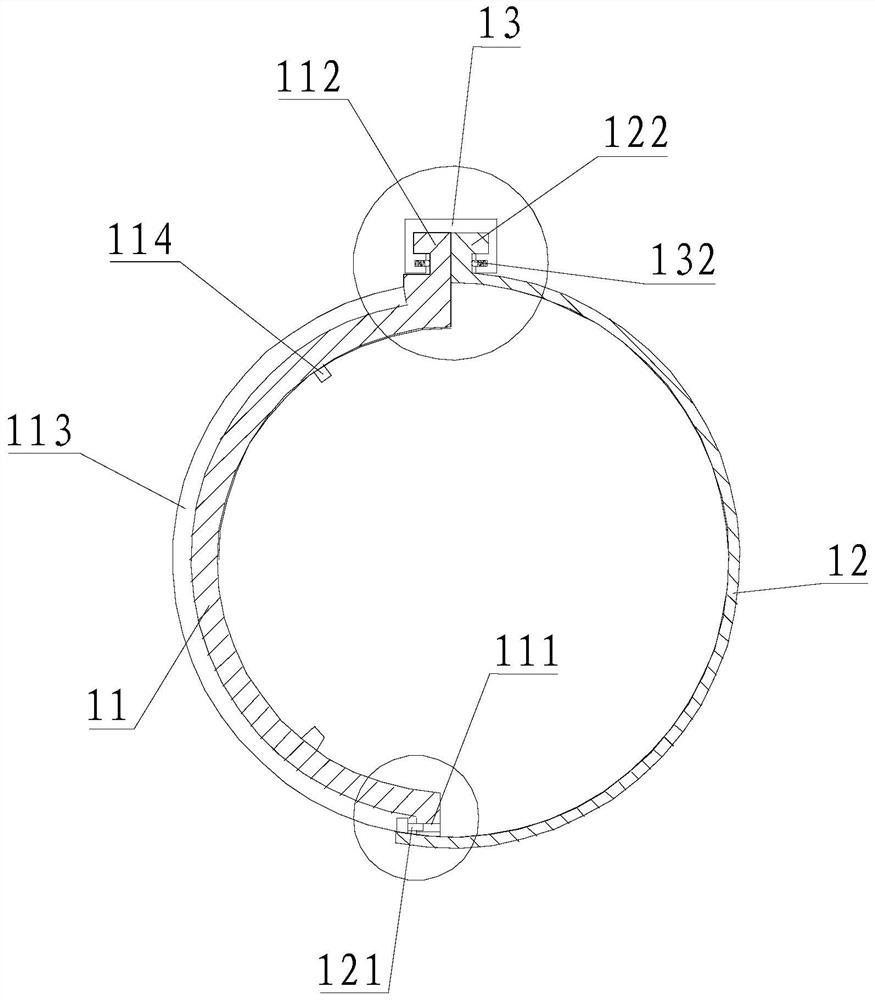

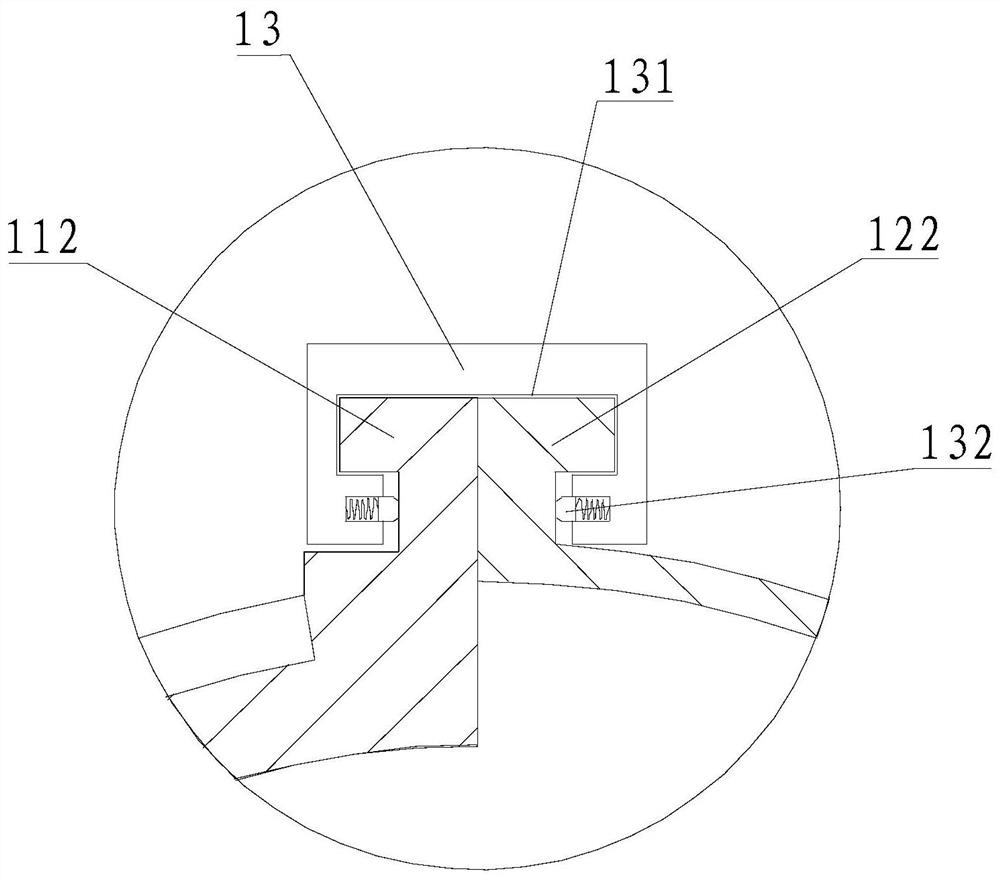

[0054] The outer tube sleeve 1 includes a left half sleeve 11, a right half sleeve 12 and a sliding sleeve 13;

[0055] The right half sleeve 12 is slidably connected to the outer wall of the left half sleeve 11 along the direction around the axis of the pipe;

[0056] The left half-sleeve 11 is attached to the left half-arc surface, the left half-arc is provided with a plurality of positioning holes 22 , and the inner wall of the left half-sleeve 11 is provided with a plurality of corresponding positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com