Settlement slowing structure for soft soil foundation shield tunnel and using method

A technology for shield tunneling and soft soil foundation, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as water leakage and continuous settlement of segments, and achieve the effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

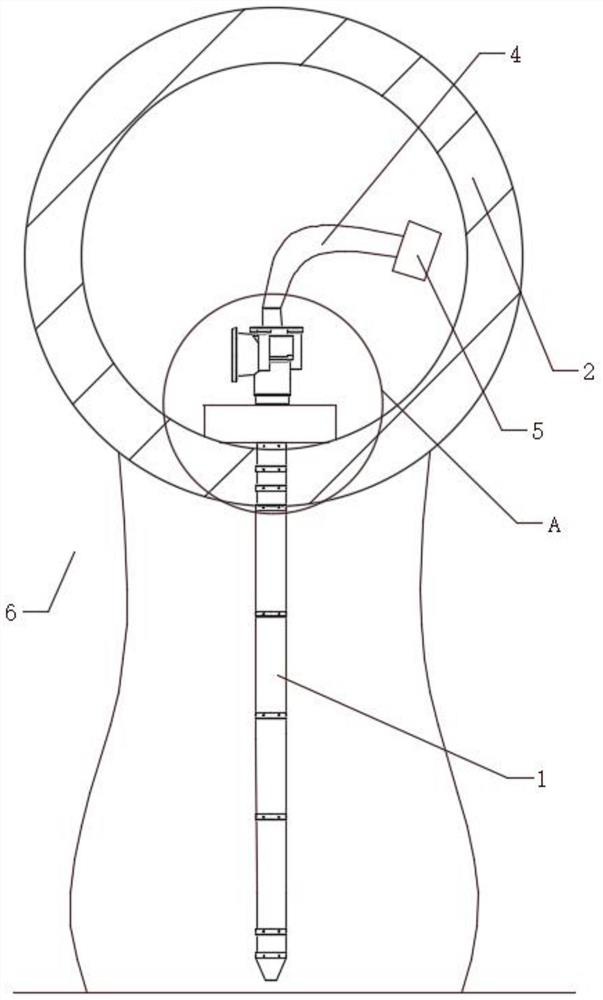

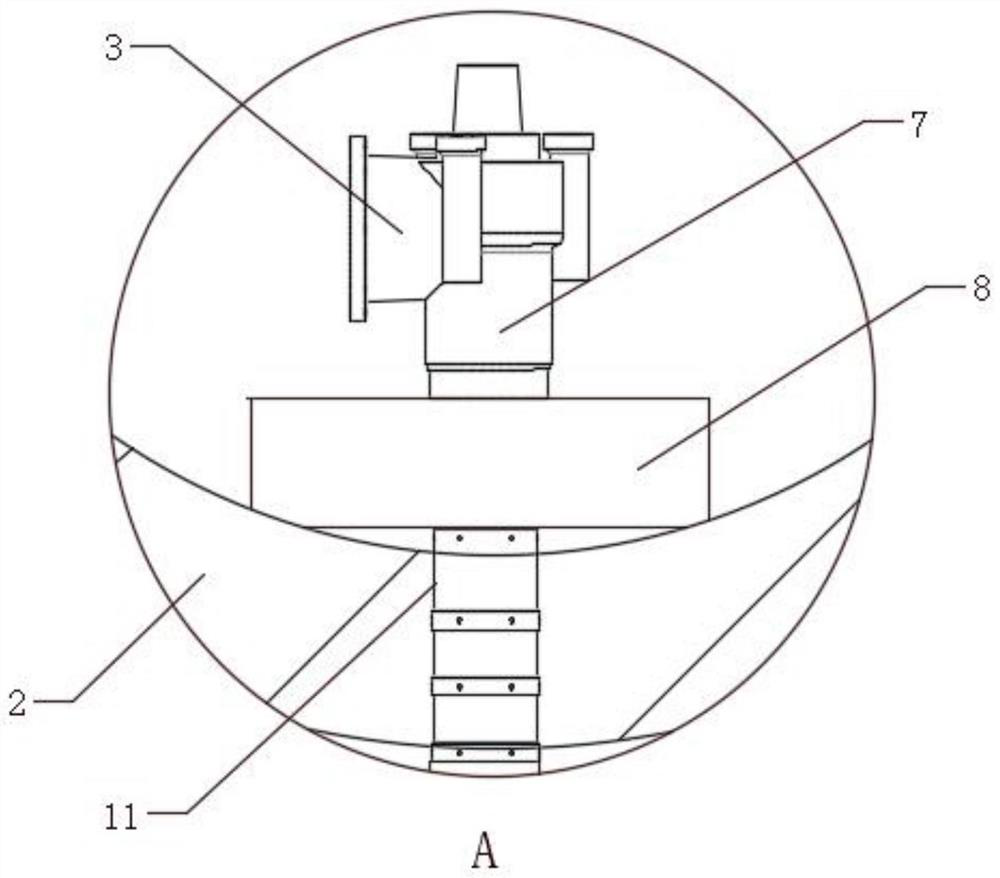

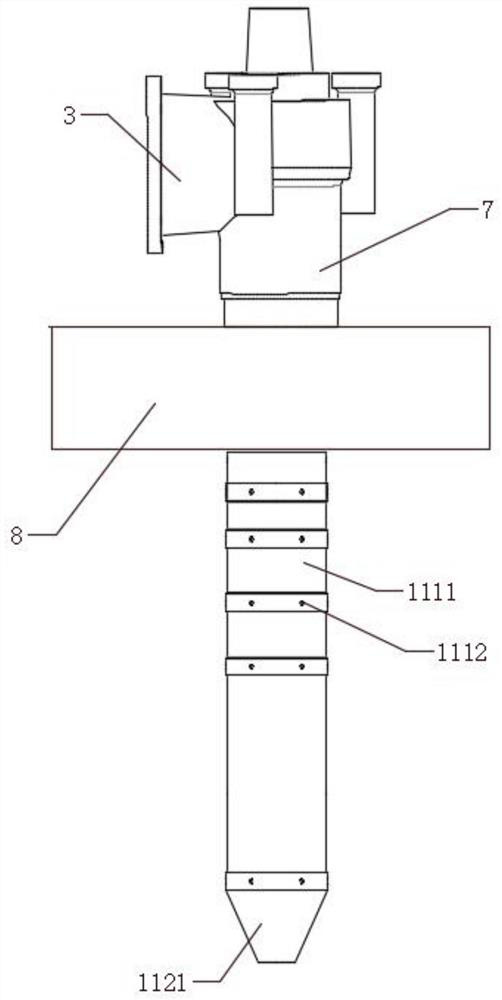

[0040] Such as Figure 1-6 As shown, a settlement slowing structure for shield tunnels on soft soil foundations of the present invention includes a mortar spraying mechanism 1, shield tunnel segments 2, grouting connection parts 3, grouting pipes 4, grouting equipment 5 and The power unit 7, the front part of the mortar spraying mechanism 1 penetrates the shield tunnel segment 2 and extends into the soft soil 6, the tail of the mortar spraying mechanism 1 is rotationally connected with the power unit 7, and the grouting connection part 3 is opened on the power unit 7 On the outside, the grout connection part 3 communicates with the mortar spraying mechanism 1 , and the grouting connection part 3 is connected with the grouting equipment 5 through the grouting pipe 4 . Due to the effect of grouting in the construction of the tunnel anti-settlement structure in the prior art, the uneven spraying of mortar will generate excess pore water pressure in the formation, and the formatio...

Embodiment 2

[0045] Such as Figure 1-6 As shown, a settlement slowing structure for shield tunnels on soft soil foundations of the present invention includes a mortar spraying mechanism 1, shield tunnel segments 2, grouting connection parts 3, grouting pipes 4, grouting equipment 5 and The power unit 7, the front part of the mortar spraying mechanism 1 penetrates the shield tunnel segment 2 and extends into the soft soil 6, the tail of the mortar spraying mechanism 1 is rotationally connected with the power unit 7, and the grouting connection part 3 is opened on the power unit 7 On the outside, the grout connection part 3 communicates with the mortar spraying mechanism 1 , and the grouting connection part 3 is connected with the grouting equipment 5 through the grouting pipe 4 . Due to the effect of grouting in the construction of the tunnel anti-settlement structure in the prior art, the uneven spraying of mortar will generate excess pore water pressure in the formation, and the formatio...

Embodiment 3

[0053] Such as Figure 1-6 As shown, a settlement slowing structure for shield tunnels on soft soil foundations of the present invention includes a mortar spraying mechanism 1, shield tunnel segments 2, grouting connection parts 3, grouting pipes 4, grouting equipment 5 and The power unit 7, the front part of the mortar spraying mechanism 1 penetrates the shield tunnel segment 2 and extends into the soft soil 6, the tail of the mortar spraying mechanism 1 is rotationally connected with the power unit 7, and the grouting connection part 3 is opened on the power unit 7 On the outside, the grout connection part 3 communicates with the mortar spraying mechanism 1 , and the grouting connection part 3 is connected with the grouting equipment 5 through the grouting pipe 4 . Due to the effect of grouting in the construction of the tunnel anti-settlement structure in the prior art, the uneven spraying of mortar will generate excess pore water pressure in the formation, and the formatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com