Antibacterial composite fiber membrane and preparation method and application thereof

A technology of composite fiber membrane and mixed liquid, applied in the field of composite membrane, can solve the problems of oxidation temperature and light, volatile, sensitive, etc., achieve the effect of inhibiting Escherichia coli and Staphylococcus aureus, long action time, and broad antibacterial spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

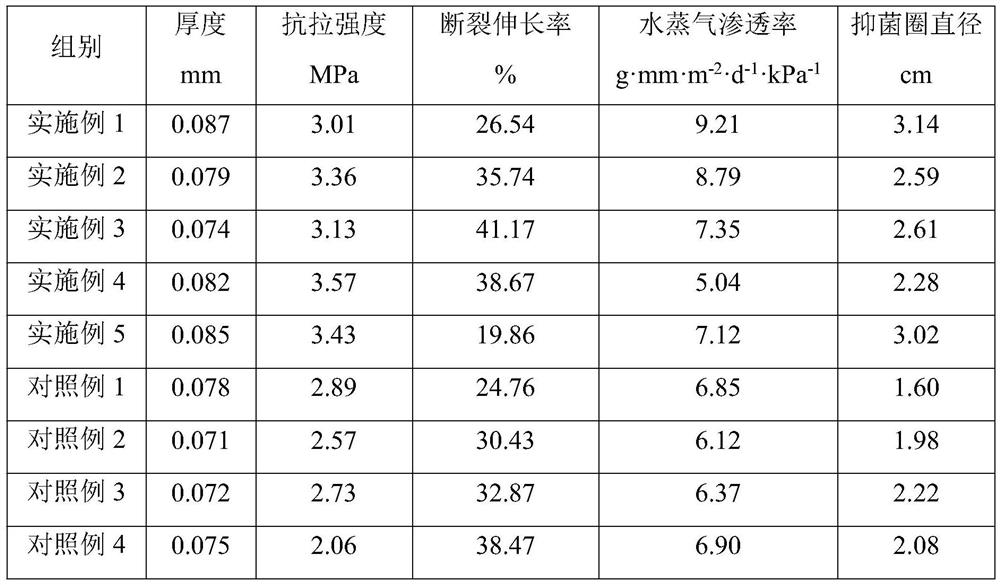

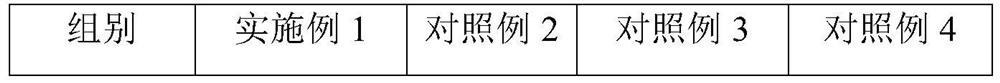

Examples

Embodiment 1

[0038] A preparation method for an antibacterial composite fiber membrane, comprising the following steps:

[0039] 1) Preparation of antibacterial microcapsules:

[0040] A1. The citronella essential oil of 1:4 (v:v) is mixed and dissolved with ethyl acetate to obtain a mixed solution;

[0041] A2. Mix and dissolve β-cyclodextrin and deionized water to obtain a supersaturated solution;

[0042] A3. Mix the 1:10 (v:v) mixture with the supersaturated solution, stir magnetically at 60°C for 120min, then freeze-thaw at -18°C for 4h, and filter with suction to obtain the precipitate;

[0043] A4. Heating and drying the precipitate to constant weight at 50° C. to obtain antibacterial microcapsules.

[0044] 2) Preparation of antibacterial composite fiber membrane:

[0045] B1. Take by weighing 3g of antibacterial microcapsules, 7g of tapioca starch, 2g of glycerin, 6g of gelatin and 100mL of deionized water;

[0046] B2. Mix tapioca starch and deionized water and stir for 20 mi...

Embodiment 2

[0050] A preparation method for an antibacterial composite fiber membrane, comprising the following steps:

[0051] 1) Preparation of antibacterial microcapsules:

[0052]A1. The citronella essential oil of 1:4 (v:v) is mixed and dissolved with ethyl acetate to obtain a mixed solution;

[0053] A2. Mix and dissolve β-cyclodextrin and deionized water to obtain a supersaturated solution;

[0054] A3. Mix the 1:10 (v:v) mixture with the supersaturated solution, stir magnetically at 60°C for 120min, then freeze-thaw at -18°C for 4h, and filter with suction to obtain the precipitate;

[0055] A4. Heating and drying the precipitate to constant weight at 50° C. to obtain antibacterial microcapsules.

[0056] 2) Preparation of antibacterial composite fiber membrane:

[0057] B1. Take by weighing 2g of antimicrobial microcapsules, 7g of tapioca starch, 2g of glycerin, 6g of gelatin and 100mL of deionized water;

[0058] B2. Mix tapioca starch and deionized water and stir for 20 min...

Embodiment 3

[0062] A preparation method for an antibacterial composite fiber membrane, comprising the following steps:

[0063] 1) Preparation of antibacterial microcapsules:

[0064] A1. The citronella essential oil of 1:4 (v:v) is mixed and dissolved with ethyl acetate to obtain a mixed solution;

[0065] A2. Mix and dissolve β-cyclodextrin and deionized water to obtain a supersaturated solution;

[0066] A3. Mix the 1:10 (v:v) mixture with the supersaturated solution, stir magnetically at 60°C for 120min, then freeze-thaw at -18°C for 4h, and filter with suction to obtain the precipitate;

[0067] A4. Heating and drying the precipitate to constant weight at 50° C. to obtain antibacterial microcapsules.

[0068] 2) Preparation of antibacterial composite fiber membrane:

[0069] B1. Take antibacterial microcapsule 2g, tapioca starch 5g, 3% glycerin 2g, gelatin 6g and deionized water 100mL;

[0070] B2. Mix tapioca starch and deionized water and stir for 20 minutes, heat to 100°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com