Sphingomonas and technology of sphingomonas to produce high-quality welan gum

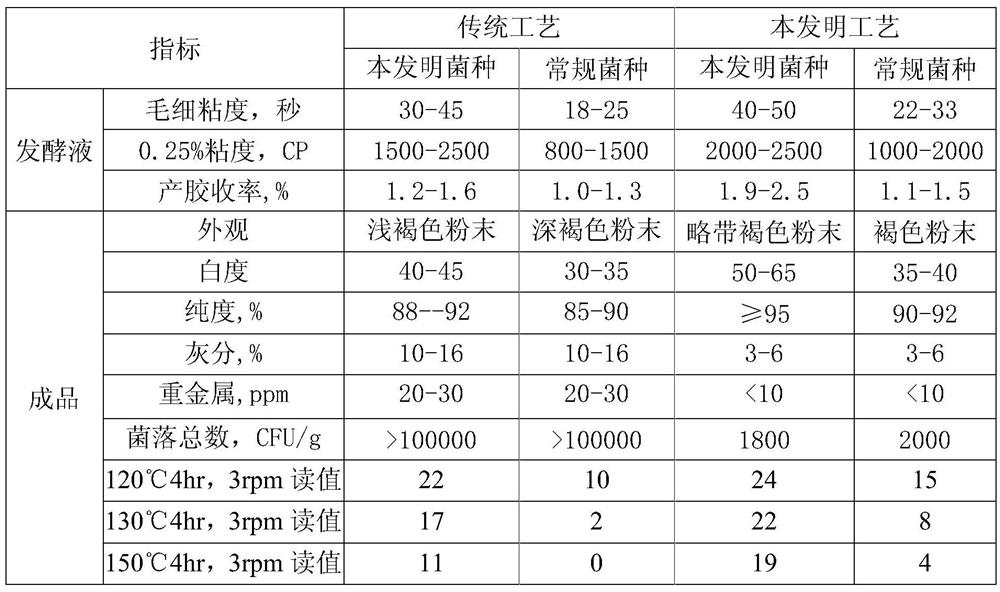

The technology of sphingomonas and warm wheel glue is applied in the field of sphingomonas and its production of high-quality warm wheel glue, which can solve the problem that the temperature resistance of warm wheel glue is not outstanding, the dehydration is difficult, and the temperature resistance time is poor. It can improve the high temperature stability of product whiteness and viscosity, the strong ability of isopropanol to dissolve pigments, and the stable improvement of output and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

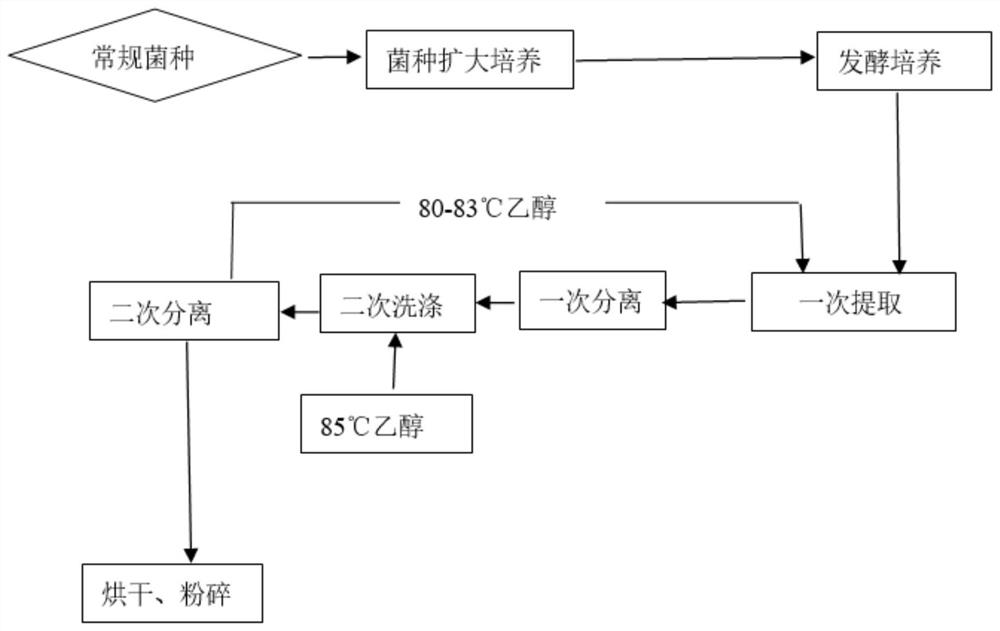

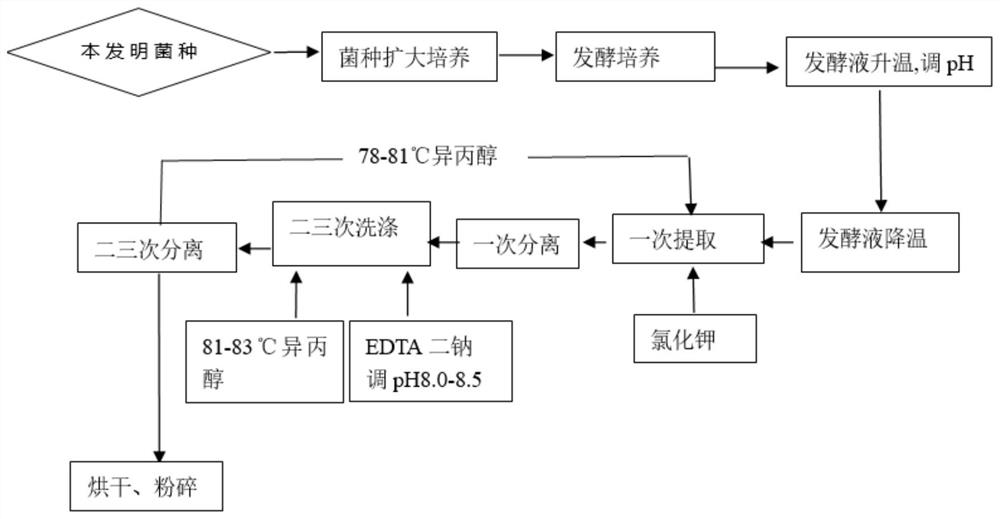

Method used

Image

Examples

Embodiment 1

[0029] Sphingomonas screening process:

[0030] 1. Material preparation

[0031] 1. Incline medium: 1.5% sucrose, 0.8% sodium chloride, 1.5% peptone, 0.3% beef extract, 0.65% yeast extract, 2.5% agar pH7.1;

[0032] 2. Fermentation medium: 2.5% glucose, 0.25% soybean protein powder, 0.05% NaCl, CaCO 3 0.2%, adjust the pH to 6-8.

[0033] 2. Breeding of strains

[0034] The original strains were subjected to plasma mutagenesis, and 50 strains were selected, and the selected strains were inoculated into the culture medium of the triangular flask, and after one, two, and three generations of subculture, the yield and quality indicators were analyzed, and the strain number DS320519 was found. Yield increased the most, product quality index improved significantly. DS320519 was subjected to multiple passage shake flask experiments, and the yield and quality indicators of the strain were stable.

[0035] For the evaluation of genetic stability, DS320519 was subjected to multipl...

Embodiment 2

[0039] A process for producing high-quality warm rubber, comprising the following steps:

[0040] (1) Preparation of fermentation strains: Sphingomonas DEOSEN-DS320519 stored at 4°C was inoculated into the seed medium, cultured at 30-32°C, and cultured for 24-36 hours.

[0041] The formula of 100ml seed medium: peptone 1g, glucose 0.5g, yeast powder 0.05g, salt 0.1g, calcium carbonate 0.02g, water 100g;

[0042] Fermentation medium: glucose 3.5-4.5%, soybean protein 0.8-1.0%, salt 0.01-0.05%, CaCO 3 0.1-0.3%, adjust the pH to 6.8-8.2.

[0043] (2) Liquid fermentation:

[0044] The seed liquid is cultivated at 30°C for 24-36 hours, then connected to the seed tank for expanded cultivation, the temperature is 30-32°C, the ventilation ratio is 0.9-1.0, and the cultivation is 36-48 hours; the fermentation conditions are: temperature 30-32°C; ventilation ratio 0- 0.2-0.3 in 24 hours, 0.4-0.5 in 24-48 hours, 0.7-1.0 after 48 hours; pH maintained at 6.8-8.2; fermentation time 65-72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com