Pulse energy storage ceramic material and preparation method thereof

A ceramic material and energy storage technology, which is applied in the field of pulse energy storage ceramic materials and its preparation, can solve the problems of low BDS and low energy storage density, and achieve the effects of stable performance, improved performance, and high electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0029] Embodiment 1-7 (does not contain modifying additive)

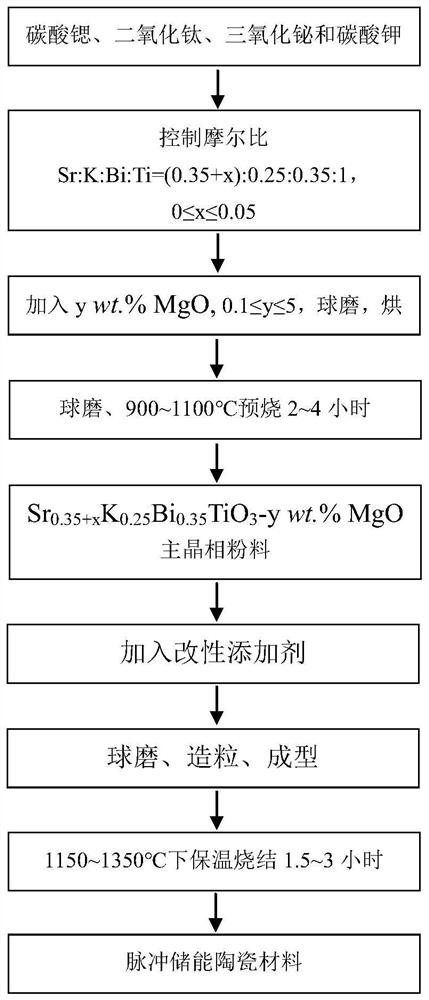

[0030] A preparation method of a pulse energy storage ceramic material, comprising the following steps:

[0031] first step:

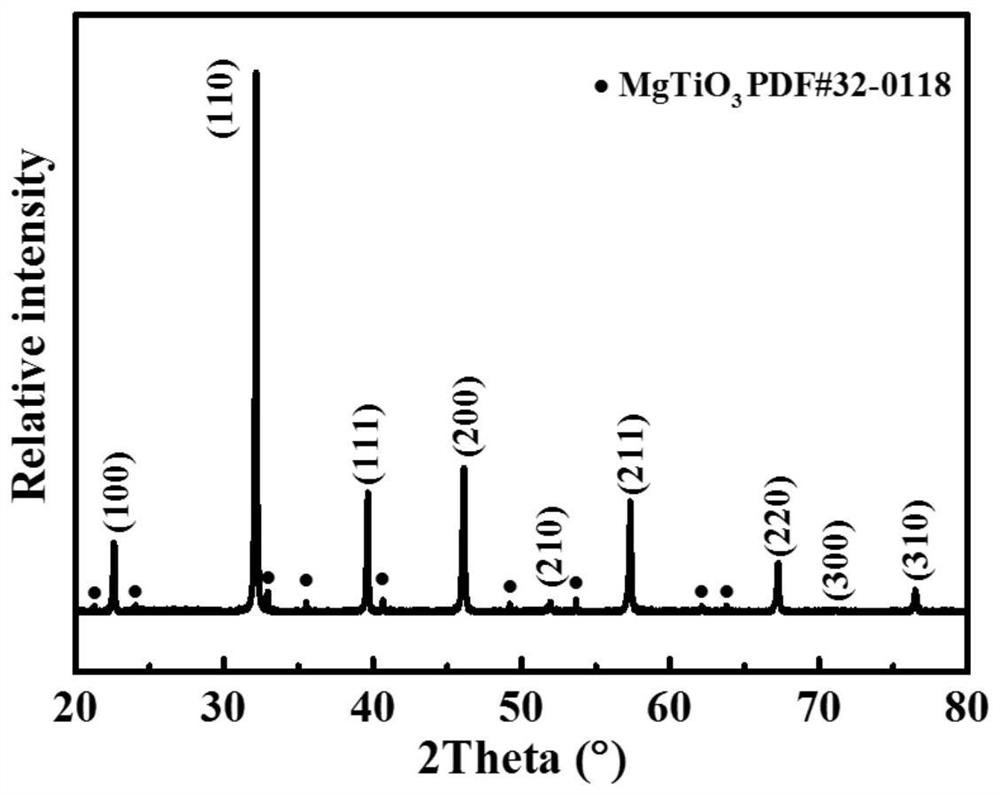

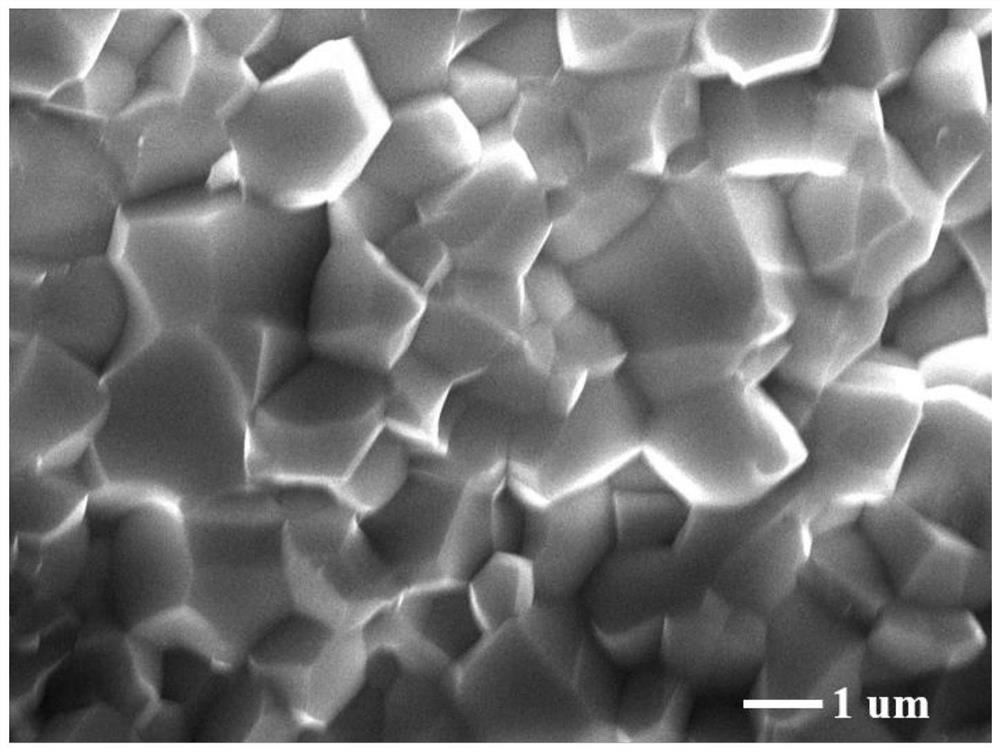

[0032] Sr 0.35+x K 0.25 Bi 0.35 TiO 3 Powder is synthesized; Be respectively 99% strontium carbonate, 99.5% titanium dioxide with purity, 99.5% bismuth trioxide, 99% salt of wormwood as starting material, accurately weigh each raw material of starting material according to the ratio in table 1, control The molar ratio between Sr, K, Bi and Ti is Sr:K:Bi:Ti=(0.35+x):0.25:0.35:1, where 0≤x≤0.05, after mixing uniformly by ball milling at 900~1100℃ Heat preservation and pre-fire for 2 to 4 hours, then cool down with the furnace to obtain Sr 0.35+x K 0.25 Bi 0.35 TiO 3 Powder; the ball milling process is as follows: use zirconia balls as the ball milling medium, use deionized water as the solvent, and carry out ball milling according to the weight ratio of material, balls and water as 1:...

Embodiment 8-17

[0044] Embodiment 8-17 (containing modification additive)

[0045] first step:

[0046] Step 1: Sr 0.35+x K 0.25 Bi 0.35 TiO 3 Synthesis of powder: with the purity of 99% strontium carbonate, 99.5% titanium dioxide, 99.5% bismuth trioxide, and 99% potassium carbonate as starting materials, 45.843g of strontium titanate, 68.919g of titanium dioxide, and bismuth trioxide 70.336g, potassium carbonate 14.902g, control the molar ratio between Sr, K, Bi and Ti to be Sr:K:Bi:Ti=(0.35+x):0.25:0.35:1, wherein x=0.01, ball mill and mix uniformly Afterwards, heat preservation and pre-calcination at 900-1100°C for 2-4 hours, and cool down with the furnace to obtain Sr 0.36 K 0.25 Bi 0.35 TiO 3 Powder;

[0047] The ball milling process is as follows: use zirconia balls as the ball milling medium, use deionized water as the solvent, and perform ball milling for 3 to 12 days according to the weight ratio of material, balls and water as 1:(3~5):(0.5~1). Hour;

[0048] Step two:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com