Optimization method and optimization device for phosphoric acid production process

An optimization method and production process technology, applied in chemical instruments and methods, phosphorus compounds, chemical process analysis/design, etc., can solve problems such as high operating costs, difficult control, low utilization rate of phosphoric acid industry resources, etc., to improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

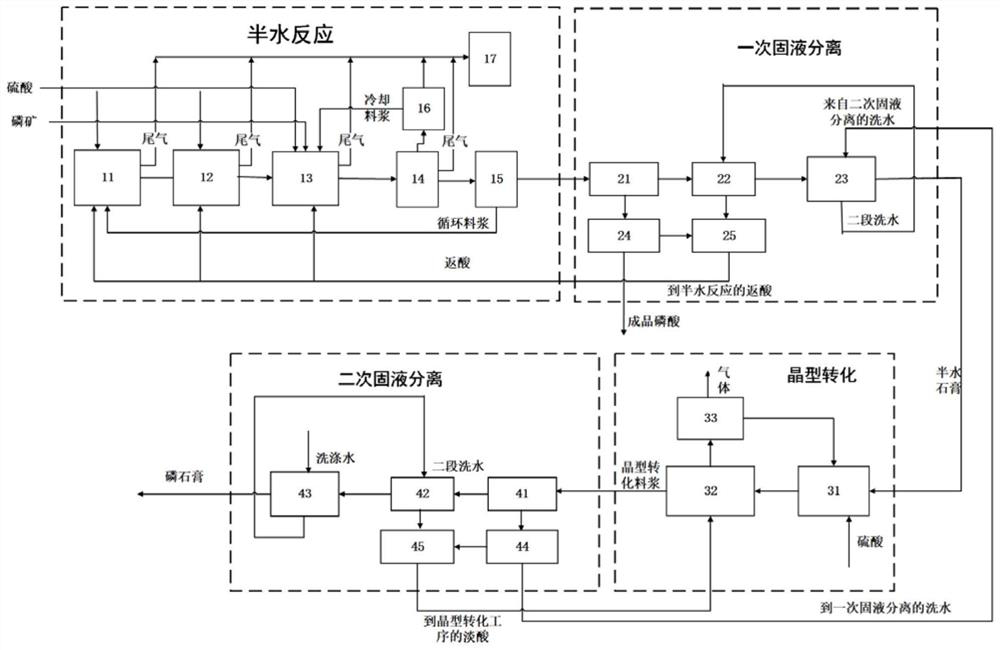

[0272] The present embodiment provides a kind of optimization method of phosphoric acid production process, and described optimization method comprises the steps:

[0273] (1') Obtain process data in wet-process phosphoric acid production;

[0274] The production process data includes raw material data, equipment parameters, process control indicators, operating parameters and product parameters; the raw material data includes raw material flow, raw material composition and raw material properties; the raw material composition includes phosphate rock composition and sulfuric acid concentration; The composition of phosphate rock includes P 2 o 5 content, CaO content, F content and SiO 2 content, etc.; the raw material properties include phosphate rock particle size and phosphate rock density; the equipment parameters include equipment flow, equipment structure and equipment characteristic parameters; the equipment characteristic parameters include the size parameters of the r...

Embodiment 2

[0456] This embodiment provides an optimization device for the production process of phosphoric acid. The optimization device includes the following modules: a data module, a mechanism model module, a model correction module, and a decision variable optimization module; the data module is used to obtain process data for phosphoric acid production; The mechanism model module is used to build and / or call the mechanism model of phosphoric acid production; the model correction module uses the process data in the data module to correct the mechanism model; the decision variable optimization module constructs a mechanism model with Constraint conditions, oriented by the optimization goal, optimize the optimization model for the decision variables, and solve the optimization model; the optimization device also includes a scheme execution module for applying the optimized decision variables to phosphoric acid production.

[0457] The optimization device can implement the optimization m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com