Automatic positioning device for movable plate feeder

An automatic positioning and feeding machine technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of major accidents such as belt corridor blockage, and achieve the effect of increased safety and reliability, improved reliability, and automatic dual positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

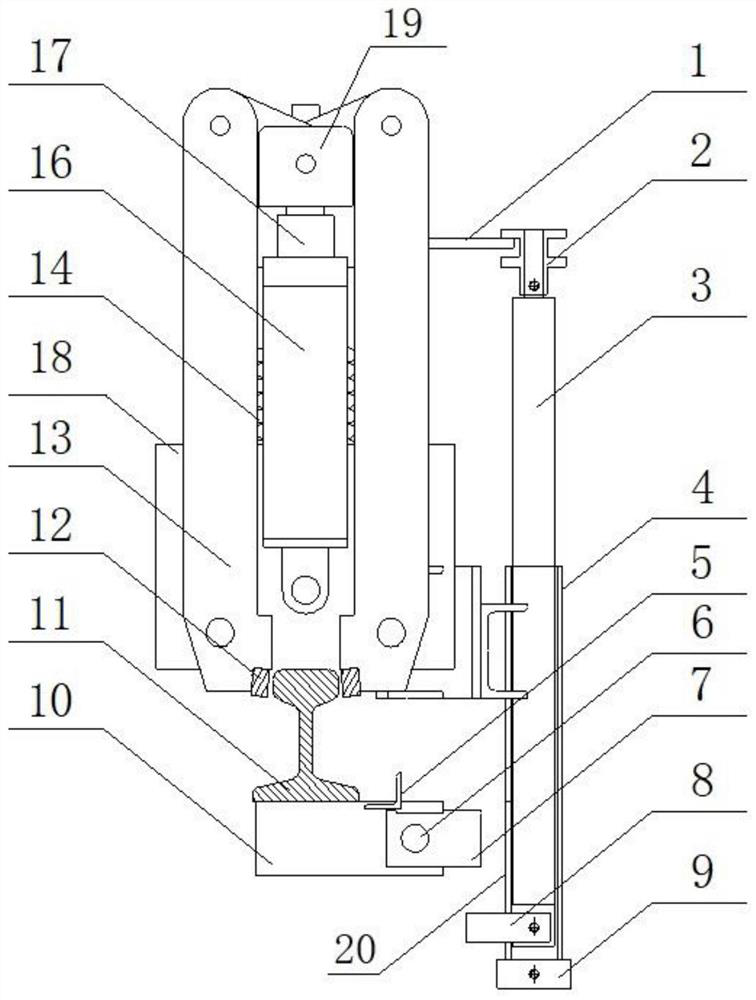

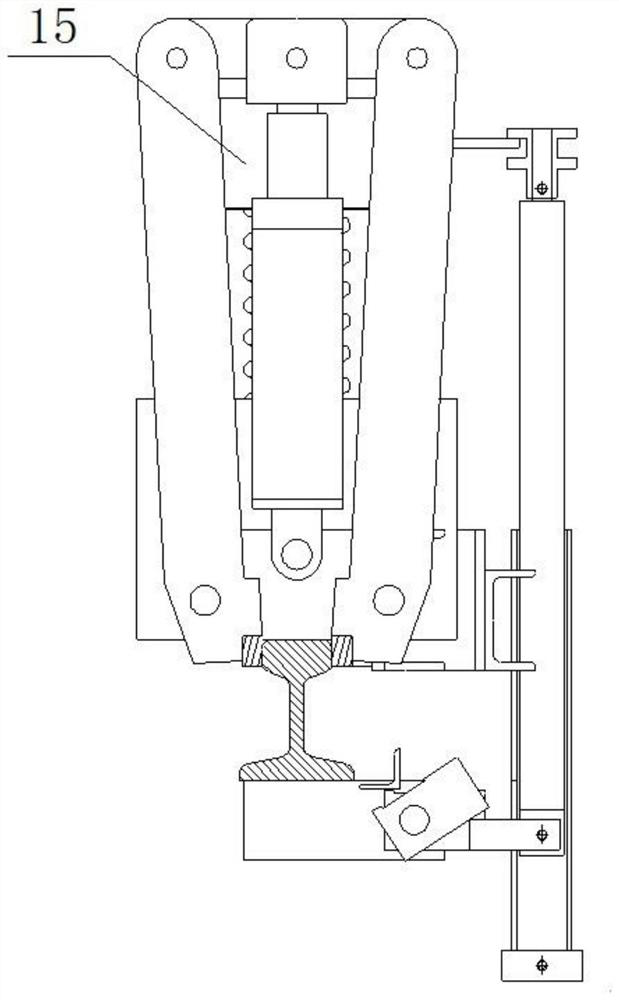

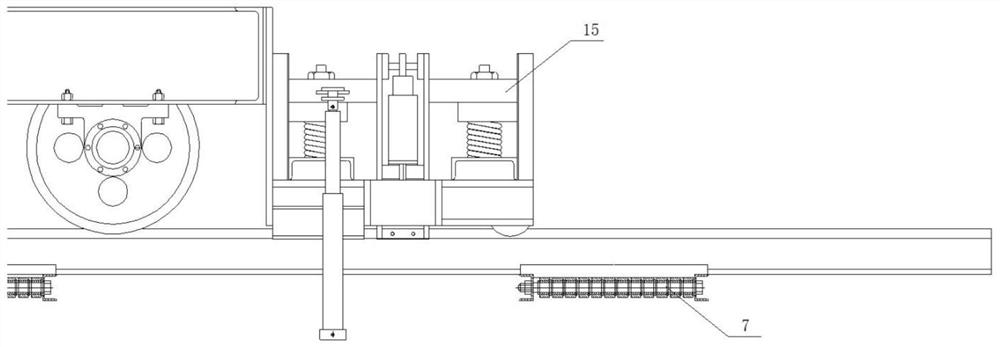

[0018] The present invention will be described in detail below in combination with specific embodiments.

[0019] Such as Figure 1-4 As shown, an automatic positioning device for moving the apron feeder, including a jaw thrust rod 13, the bottom of the jaw thrust rod 13 is equipped with a jaw 12 for clamping the transport rail, and the middle position of the top of the jaw thrust rod 13 is It is the lifting part 19, and the lifting part 19 drives it to move up and down through the piston 17 in the hydraulic thrust rod 16. The side of the lifting part 19 is connected with a spring upper pressing plate 15, and a spring 14 is fixed between the spring upper pressing plate 15 and the base 18, and the spring 14 The compression or release is realized by the movement of the piston 17 of the hydraulic thrust rod 16; the guide plate 1 is welded on the side of the spring upper pressure plate 15, and the guide limit 2 is set on the side of the guide plate 1, and the guide plate 1 moves u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com